Maintenance

Repair

434 MagneMotion

Rockwell Automation Publication MMI-UM002F-EN-P - October 2022

Required Tools and Equipment

• Screwdriver, Phillips #1.

• Loctite 243, Thread locker Anaerobic Adhesive, Blue.

• 68 viscosity EP mineral oil (Kluber 4 UH1-68N).

• Syringe or other injector.

Procedure

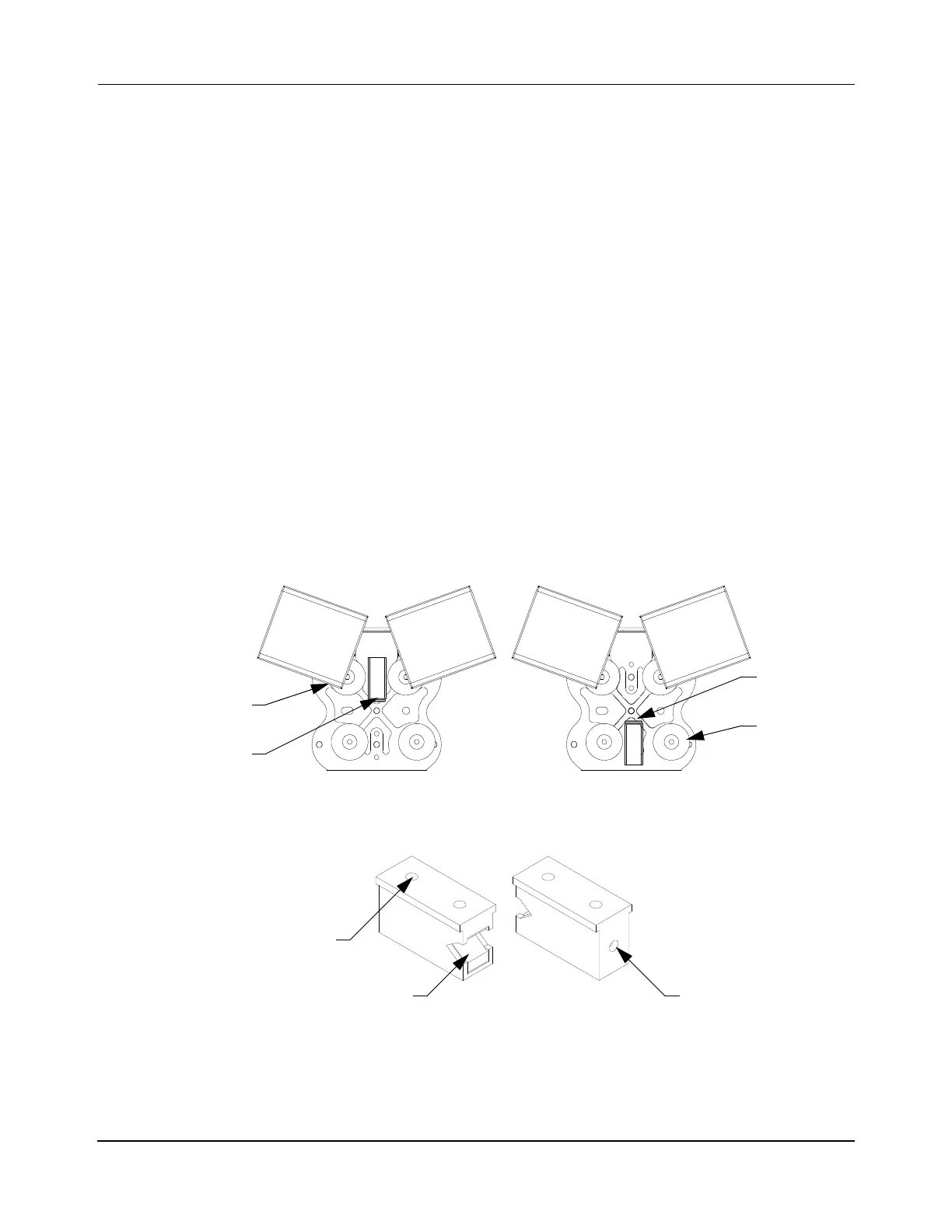

The lubricators are attached to the underside of the vehicle between either the concentric bear-

ings or the eccentric bearings as shown in Figure 7-39. Some systems can have lubricators

that are mounted in both locations on the same vehicle. The end of the felt applicator in the

lubricator always points inwards toward the rail with the refill access portal at the opposite

end of the reservoir. See Figure 7-40 for illustration of lubricator housing.

To maintain consistency between vehicles, and to apply lubricant evenly to both sides of the

rail system, MagneMotion recommends that half the vehicles be installed with the lubricator

between the concentric bearings and the other half between the eccentric bearings.

NOTE: When installing the vehicles on the rails, alternate the vehicles so that two consecu-

tive vehicles do not have the lubricator on the same side.

Figure 7-39: Precision Rail Vehicle Lubricator Locations

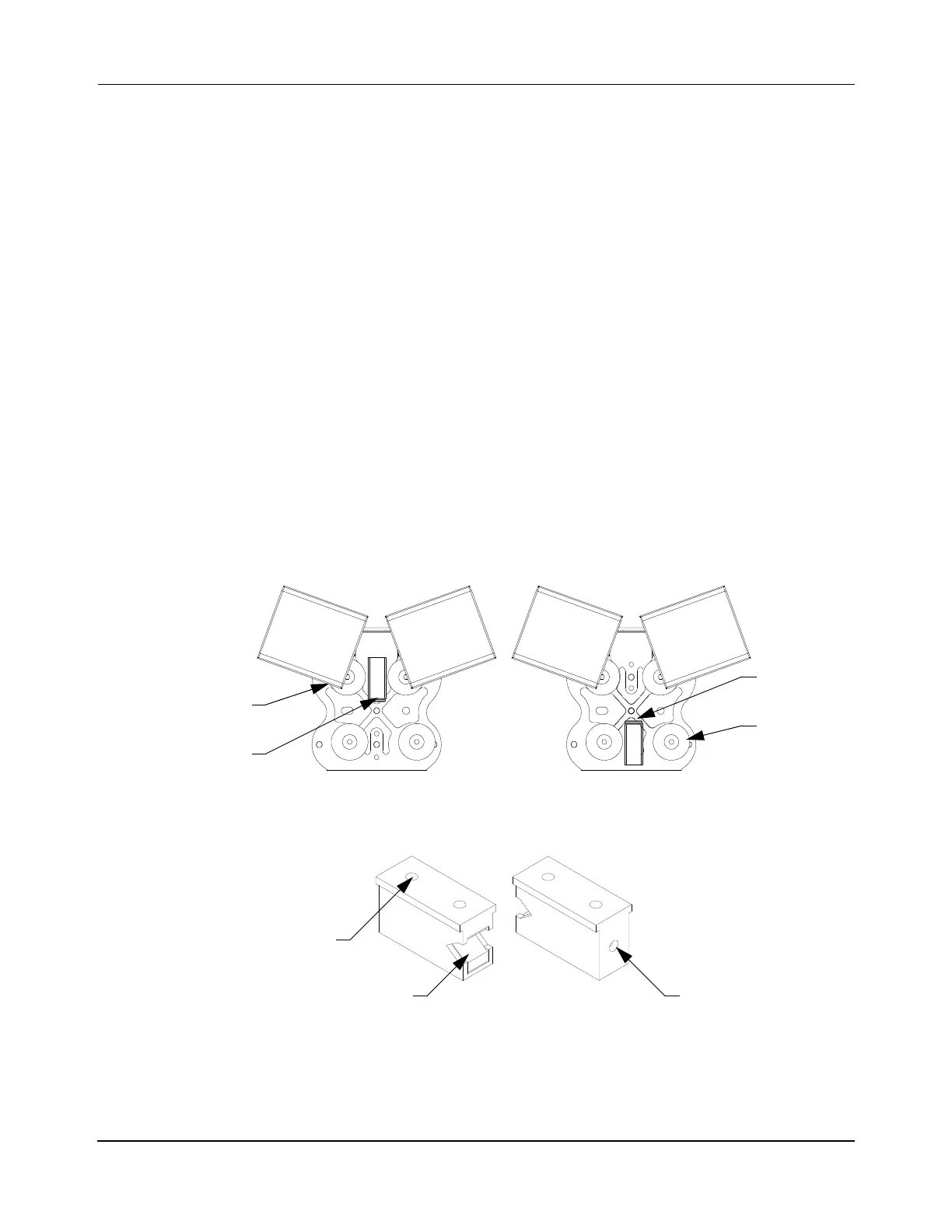

Figure 7-40: Precision Rail Vehicle Lubricator

NOTE: The felt tip contains a v-groove that must be oriented correctly to the rail. If the

v-groove does not align with the rail, excess drag is created and the vehicle cannot

move freely along the rail.

Concentric

Bearings

Lubricator

Lubricator

Eccentric

Bearings

Felt Tip

Felt Tip

Felt Tip

Mounting Holes

Oil Refill Port

(2X)

Loading...

Loading...