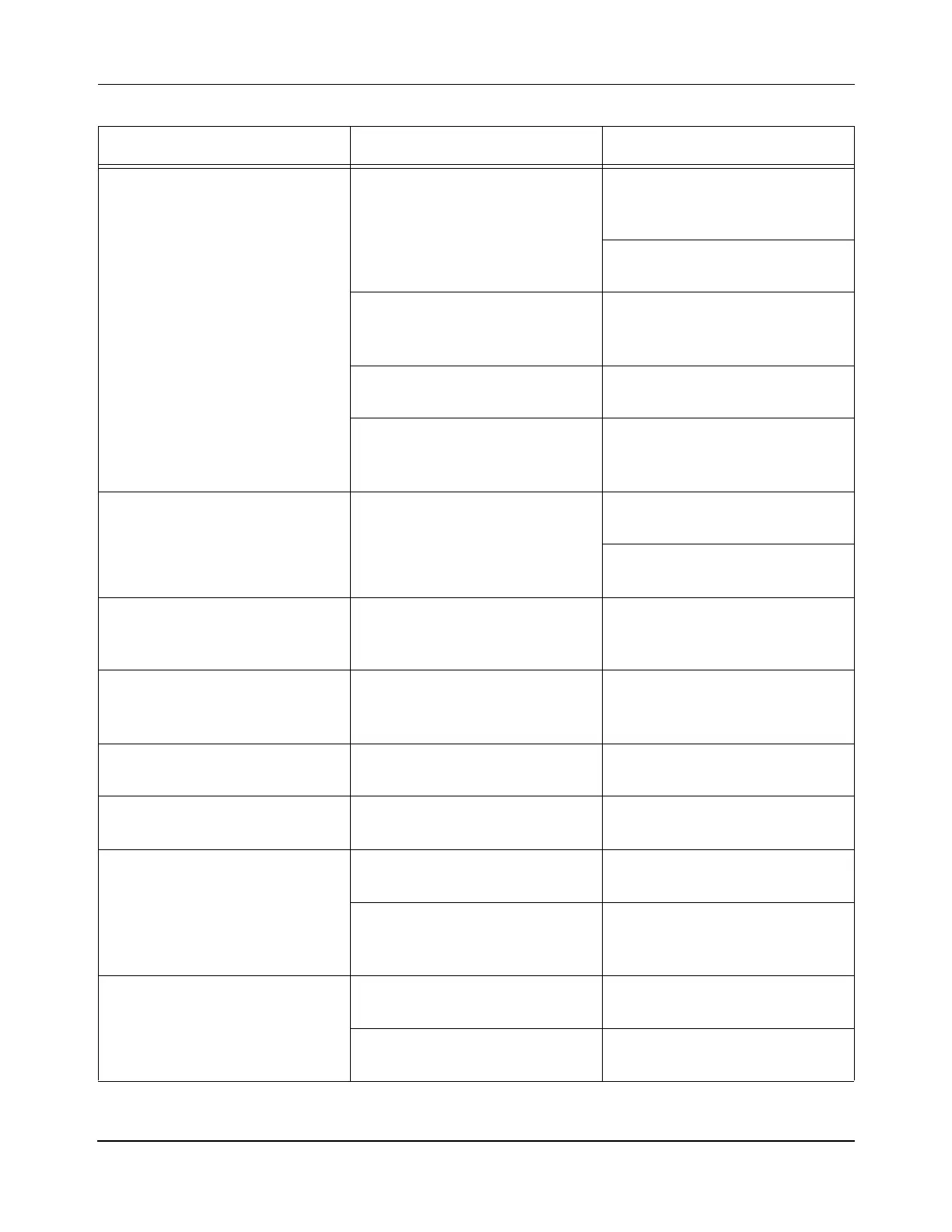

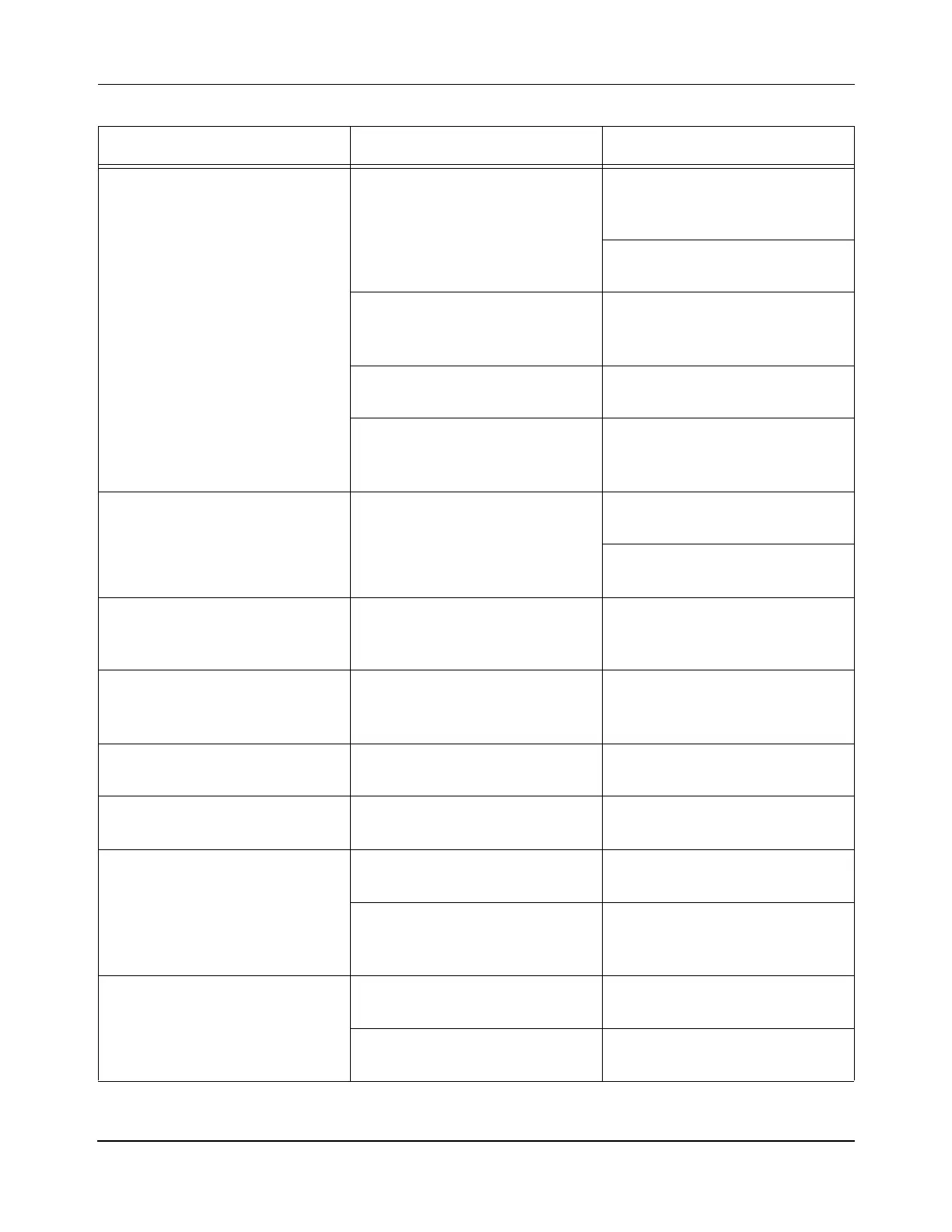

Maintenance

Troubleshooting

378 MagneMotion

Rockwell Automation Publication MMI-UM002F-EN-P - October 2022

Vehicles are loosing thrust. Misalignment or wear of sections

of the guideway.

Make sure that the vehicle gap is

consistent at all locations in the

transport system.

Make sure that the vehicle and/or

track wear is within tolerance.

Thrust lost when the vehicle

moves from motor to motor.

Make sure that the downstream

gap does not exceed 10% of the

magnet array length.

Glide puck surfaces have become

worn due to extended use.

Check wear surfaces. Replace as

necessary.

Wheeled puck suspension or lat-

eral guide wheels have high rotat-

ing friction.

Check wheel set. Replace as nec-

essary.

Damage to the frog rail in the

standard switch.

There is damage to the septum in

a wheeled puck or bogie.

Inspect and replace frog if neces-

sary.

Inspect and replace the wheeled

puck or bogie if necessary.

Tandem vehicles slow signifi-

cantly in turns.

Pivot points between bogie and

linkage plate on tandem puck

have high rotating friction.

Inspect and replace as necessary.

Tandem vehicles slow signifi-

cantly in standard switch.

Pivot points between bogie and

linkage plate on tandem puck

have high rotating friction.

Inspect and replace as necessary.

Wheeled puck slows signifi-

cantly in turns.

Suspension or lateral guide

wheels have high rotating friction.

Check wheel set. Replace as nec-

essary.

Wheeled puck slows signifi-

cantly in standard switch.

Suspension or lateral guide

wheels have high rotating friction.

Check wheel set. Replace as nec-

essary.

Wheeled puck slows signifi-

cantly in high payload switches.

Suspension or lateral guide

wheels have high rotating friction.

Check wheel set. Replace as nec-

essary.

Pivot points between bogie and

linkage plate on tandem puck

have high rotating friction.

Inspect and replace as necessary.

Wheeled puck has difficulty mov-

ing through switches.

There is damage to the suspension

or lateral guide wheel.

Check wheel set. Replace as nec-

essary.

There is damage to the septum on

a wheeled puck or bogie.

Inspect and replace the wheeled

puck or bogie if necessary.

Table 7-7: Motion Control Related Troubleshooting (Continued)

Symptom Problem Description Corrective Action

Loading...

Loading...