ReferenceModification no.

- 0 -

Page

127

Date

1997 02 01

Main

914 F

01478

13.1.2.4) Diaphragm

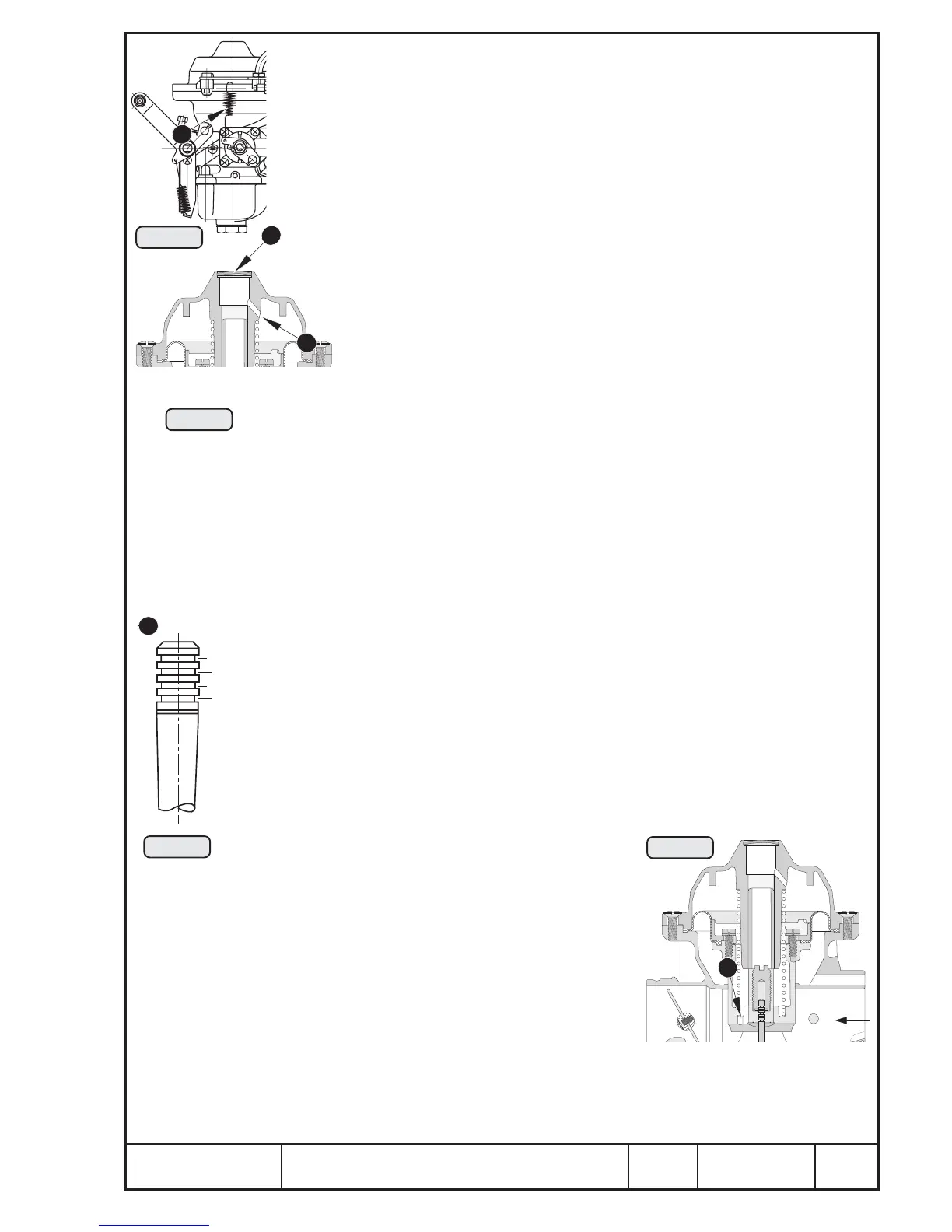

See Pic. 63/64 and 65.

Unhook spring Q of choke from start lever W and chamber top E.

◆ NOTE: The diaphragm R is linked to the plunger (carburetor

piston). Depending on the pressure prevailing, the plunger

is moved up or down.

For checking, remove the 2 countersunk screws T M5x12 and Allen screw

Y M5 along with nut and shim, remove the chamber top E and the spring

U. Check tight fit of the cover I on chamber top.

Wash chamber top with cleaning agent and blow the inside

venting bore O with compressed air, then check visually. See Pic.

65.

◆ NOTE: The diaphragm R is fixed by the retaining ring P to

the carburetor piston {.

Remove plunger from the carburetor housing and remove 4 Allen screws }

M4x12.

■ ATTENTION: The position of the carburetor piston is controlled via the

diaphragm. On the diaphragm there are 2 positioning

noses. The nose q fits exactly in the recess in the plunger,

nose w must engage in the recess in the carburetor hous-

ing.

Check diaphragm for cracks or brittleness, replace if necessary.

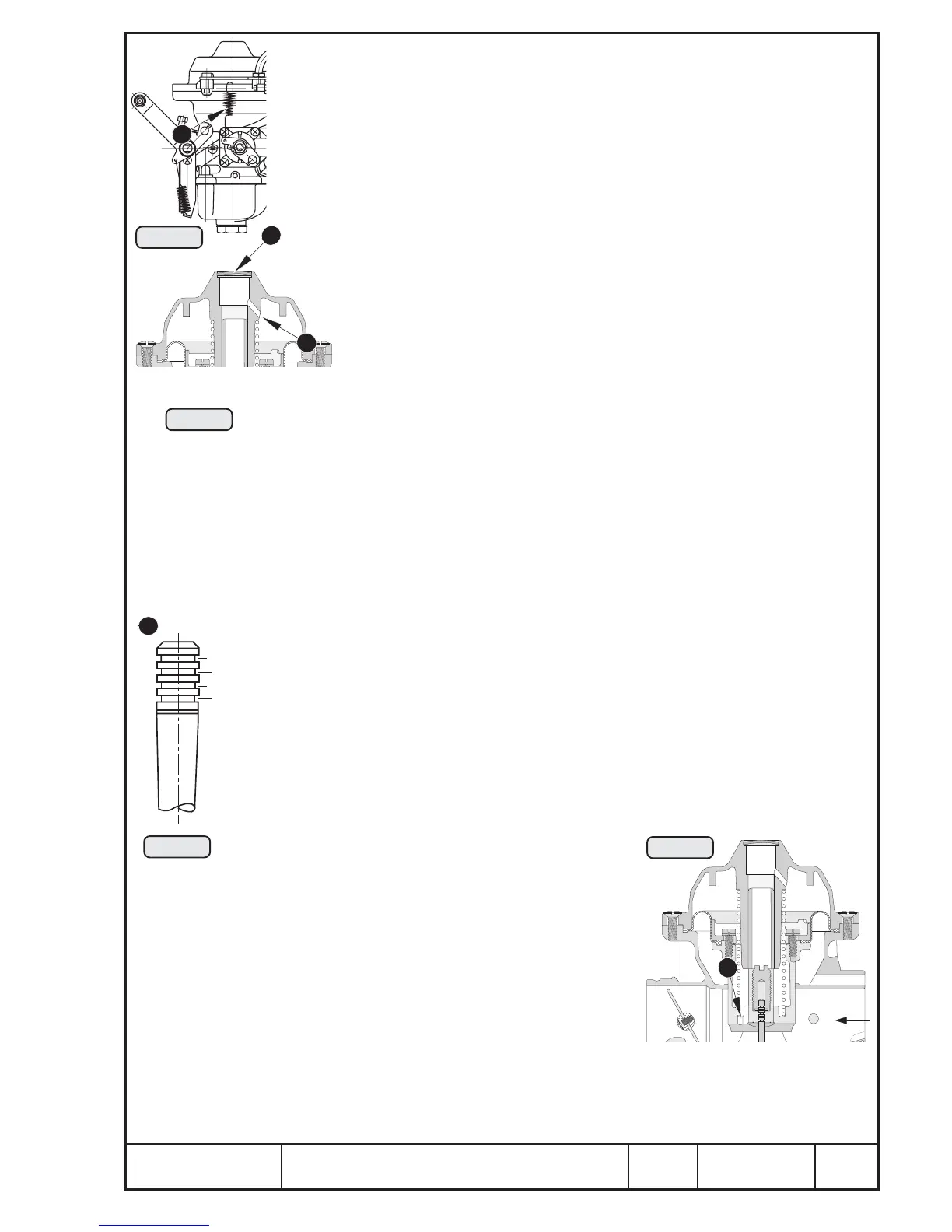

13.1.2.5) Jet needle, carburetor piston

See Pic. 63/66 and 67.

The jet needle e controls the fuel consumption at part load. It may be

regulated by choosing position of jet needle between 1 and 4.

Modifications are allowed only after consultation with the engine manufac-

turer.

◆ NOTE: A higher position causes "deeper plunging" of the jet

needle into the needle jet r ➍ smaller flow diameter ➍

leaner mixture.

Lower position ➍ richer mix-

ture.

Remove fixation screw t and check jet nee-

dle e with circlip y for wear. Pay special

attention to the grooves and the taper of the

needle. At visible wear the jet needle must be

exchanged and refitted in the same position.

■ ATTENTION: The jet needle fitted must

move freely.

Visually check outside of plunger { and the

two inside compensation bores u.

00032

Nadelposition

(needle position)

1

4

3

2

00033

Pic. 65

Pic. 66

00032

Pic. 67

1

00025

Pic. 64

8

9

15

19

Loading...

Loading...