0

10

20

30

40

50

60

70

80

90

0.01mm

1

2

3

4

5

6

7

8

9

0

Maß/dim.

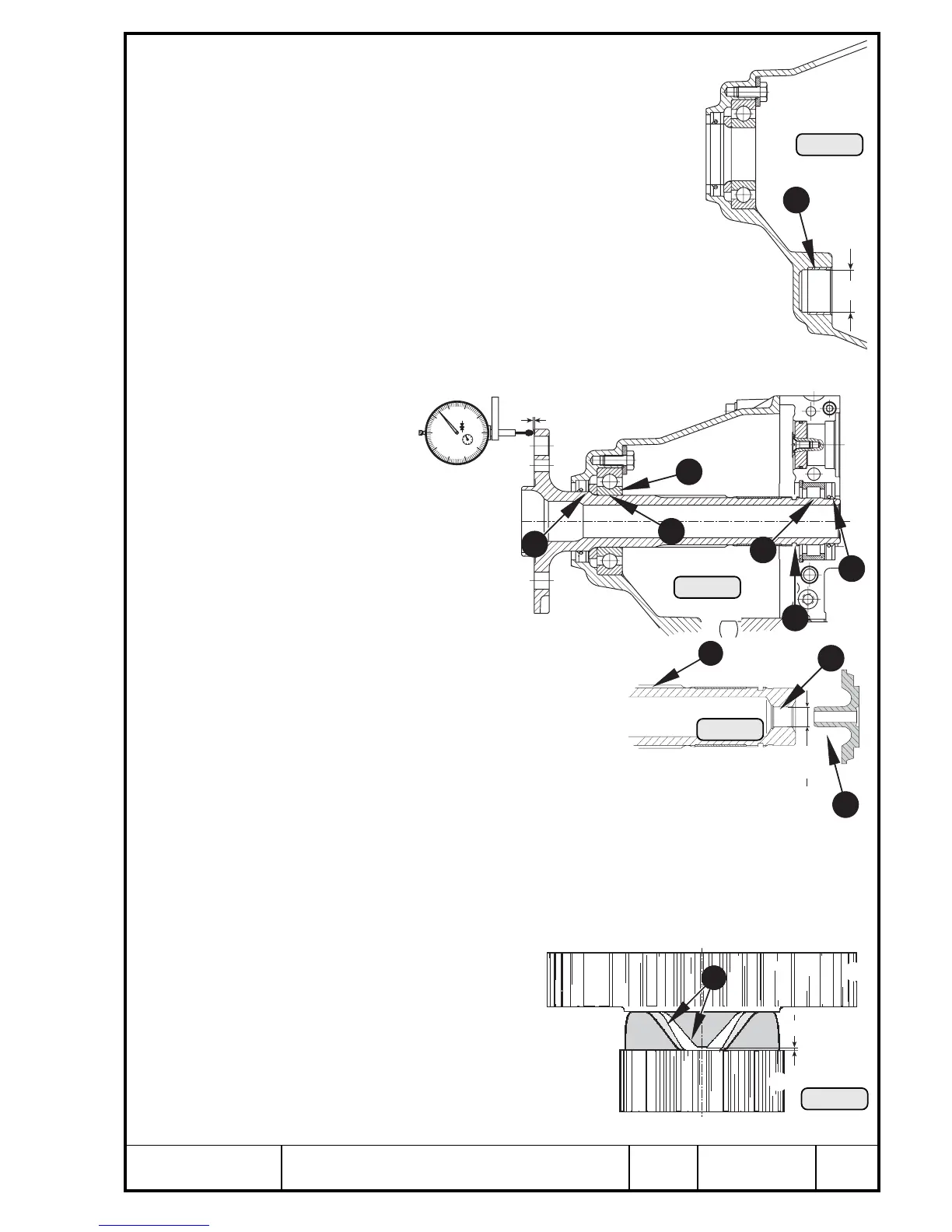

14.4.12)Gearbox components — checking

See Pic. 232, 233, 234, 235, 236 and 237.

Clean disassembled gearbox with kerosine or gaso-

line and check the following components:

➪ Check crankshaft bearing bush Q fitted in gear

cover for tight fit, check dimension {, see Chapter

15).

➪ Check both bearing seats W and E on propeller

shaft. See dimensions } and q in Chapter 15).

Check oil seal contact surfaces R and T. Check

propeller flange for out of true, see dimension w in

Chapter 15).

➪ Propeller shaft must be without corrosion on bearing seats

W and E. The ball bearing Y 6207 E (35-72-17) must be a

press fit on its outer

race in gear

cover and its

inner race on

propeller shaft.

Check groove U for ring

halves and teeth I for

wear or damage.

On version F3 check the

inner diameter O in the

area of the oil inlet flange

P, see dimension e in

Chapter 15).

Inspect propeller shaft for cracks by mag-

netic particles inspection method

(Magnaflux), see Chapter 11.4). Check

tangential intensity of magnetic field with

test instrument DEUTROMETER 3870.

Nominal value is 10 ÷ 50 A/cm. At indication of cracks renew

the respective part. Clean and demagnetize the part. The

maximum remaining magnetism must not exceed 1,2 A/cm.

Register the results of the magnetic particle inspection in the

respective Form Sheet, see Chapter 16.4).

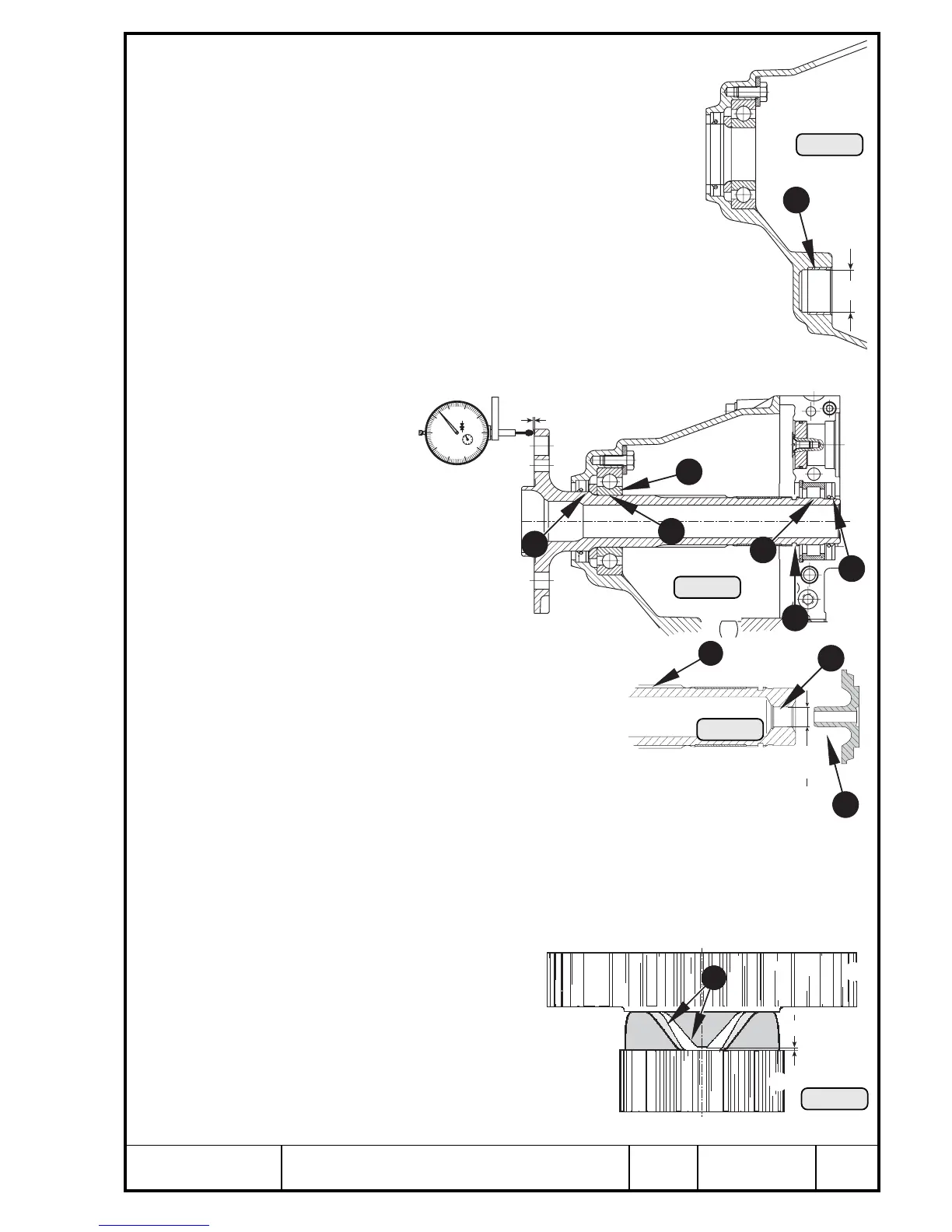

➪ Visually check dog gear { and dog hub } for pitting on gear teeth and

sliding ramps q of dogs. Ensure that ramp tops of the dog gear are

clearing ramp valleys of dog hub. Check clearance, dimension r in

Chapter 15). Slight wear and

pitting on the dogs is permissi-

ble.

3

2

5

4

6

7

Pic. 233

1

Maß

dim.

Pic. 234

9

8

10

Loading...

Loading...