Reference

Modification no.

- 0 -

Page

255

Date

1997 02 01

Main

914 F

01480

14.7) Hydraulic valve tappets

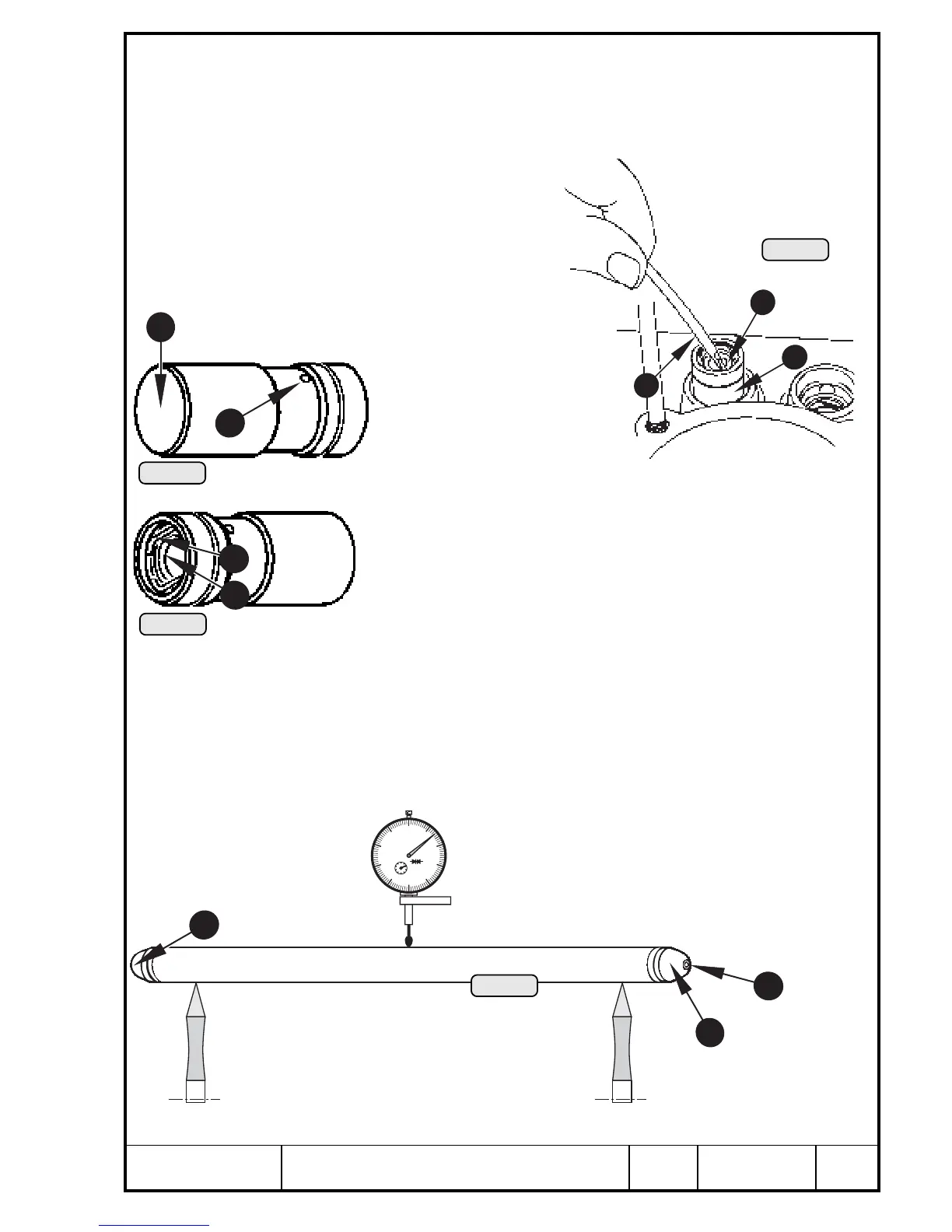

See Pic. 264, 265 and 266.

Remove valve tappet Q from crankcase using a specially shaped screwdriver W.

Never engage at circlip E. This could cause valve tappet to fall apart.

■ ATTENTION: Lay aside tappets in a

manner to ensure refitting

in their initial place.

Check valve tappet visually. The tappet

rotates during operation. Therefore the cam

contact surface R is worn evenly. If the

tappet does not rotate, the contact face will

be worn unevenly. In case of uneven wear

replace the tappet. The tappets are not allowed

to be ground on their face!

If a valve tappet must be re-

placed, check carefully the

respective cam on camshaft.

Taking apart valve tappets is

not planned and not neces-

sary.

The new valve tappet is supplied dry and will fill itself full with oil

during starting procedure. Oil enters the valve tappet through bore

T. The securing ring E keeps the valve tappet plunger Y in

position when the tappet is removed.

■ ATTENTION: The first cranking of a repaired engine should be

without ignition, until the required oil pressure is built up.

14.8) Push rods

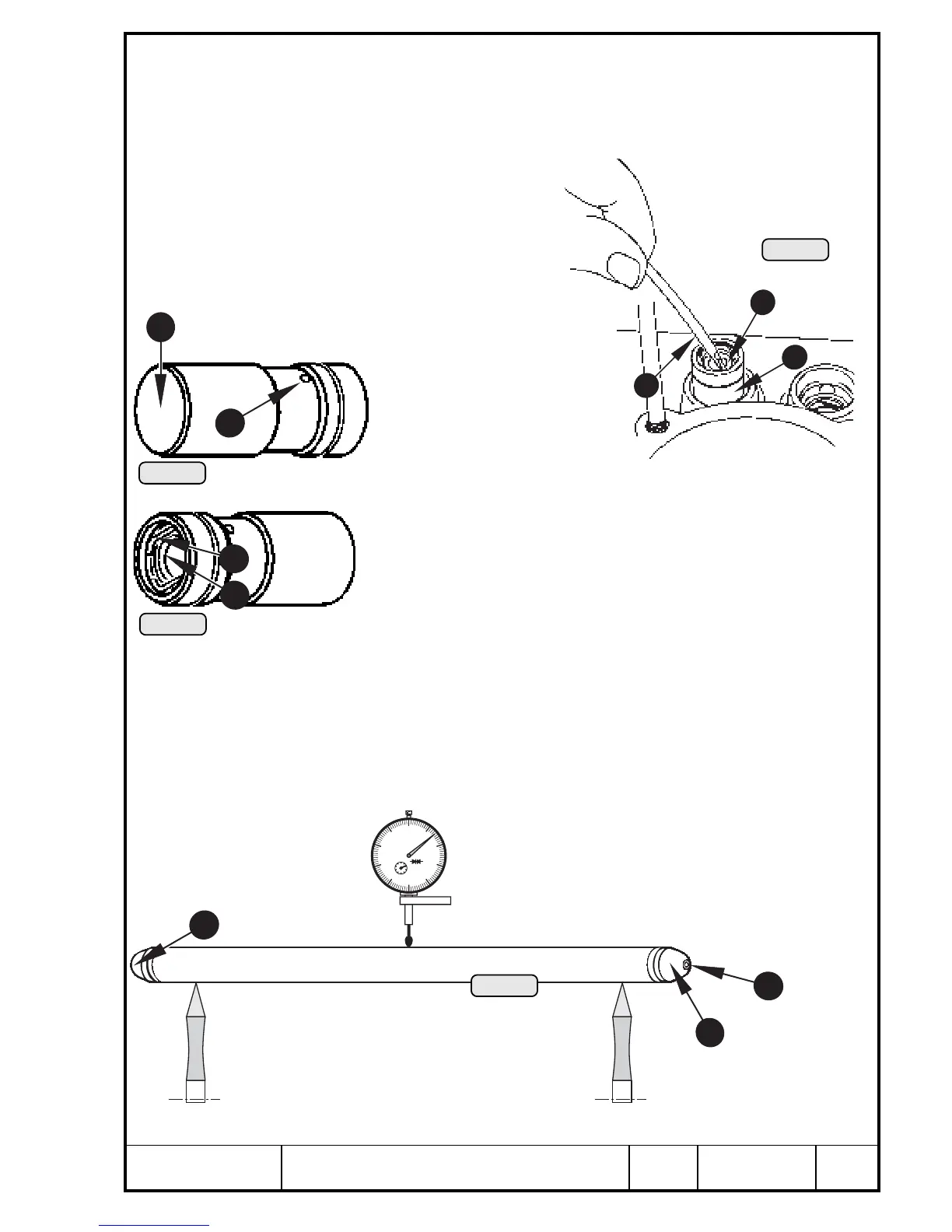

See Pic. 267.

Clean push rods Q and inspect them visually. Pay attention to tight fit of the two ball

heads W pressed into the rod. Excessive engine speed may have caused bending

of the push rods. Check push rods for straightness. Through the bores E oil passes

from the valve tappet to the rocker arm.

5

Pic. 266

Pic. 265

4

2

Pic. 264

6

3

3

1

0

10

20

30

40

50

60

70

80

90

0.01mm

1

2

3

4

5

6

7

8

9

0

2

Pic. 267

Q

3

2

00301

00300

00302

00299

Loading...

Loading...