Reference

Modification no.

- 0 -

Page

238

Date

1997 02 01

Main

914 F

01480

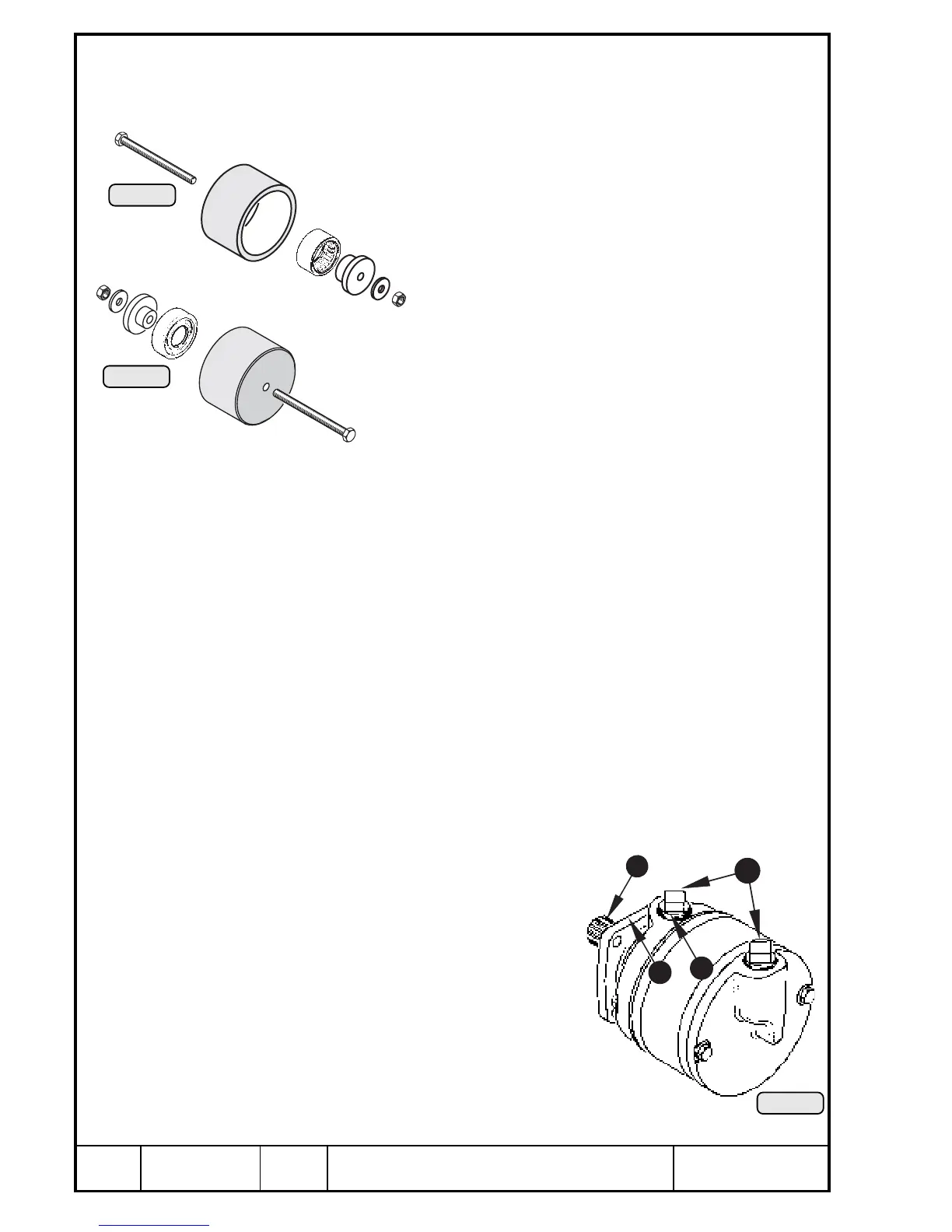

14.4.6) Drive for vacuum pump and propeller governor - re-fitting

See Pic. 219, 220 and 221

Lubricate new needle sleeve E. Position puller cap P, part no. 876 489 on

gearbox side, place press-in tool, part no. 877 579 { onto the needle sleeve

and fix with hex. nut }. Turning the hex. screw q clockwise, the needle

sleeve is pressed in completely.

The ball bearing W is pressed in with same procedure,

however, the puller cap P part no. 876 489 is fitted on

pump flange side, and the press-in tool w, part no.

877 595, is used.

Then press in new oil seal O with assembly punch,

part no. 877 276 and grease it. Apply LOCTITE 221

to countersunk screw U M5x12 and washer I for

ball bearing fixation and tighten.

Fit vacuum pump gear R and fix drive sleeve T

with holder, part no. 242 660. Apply LOCTITE 221

on Allen screw Y M8x14 and turn in.

■ ATTENTION: The length of Allen screw Y M8x14 must be absolutely

respected as otherwise the screw will collide with the drive

shaft of vacuum pump.

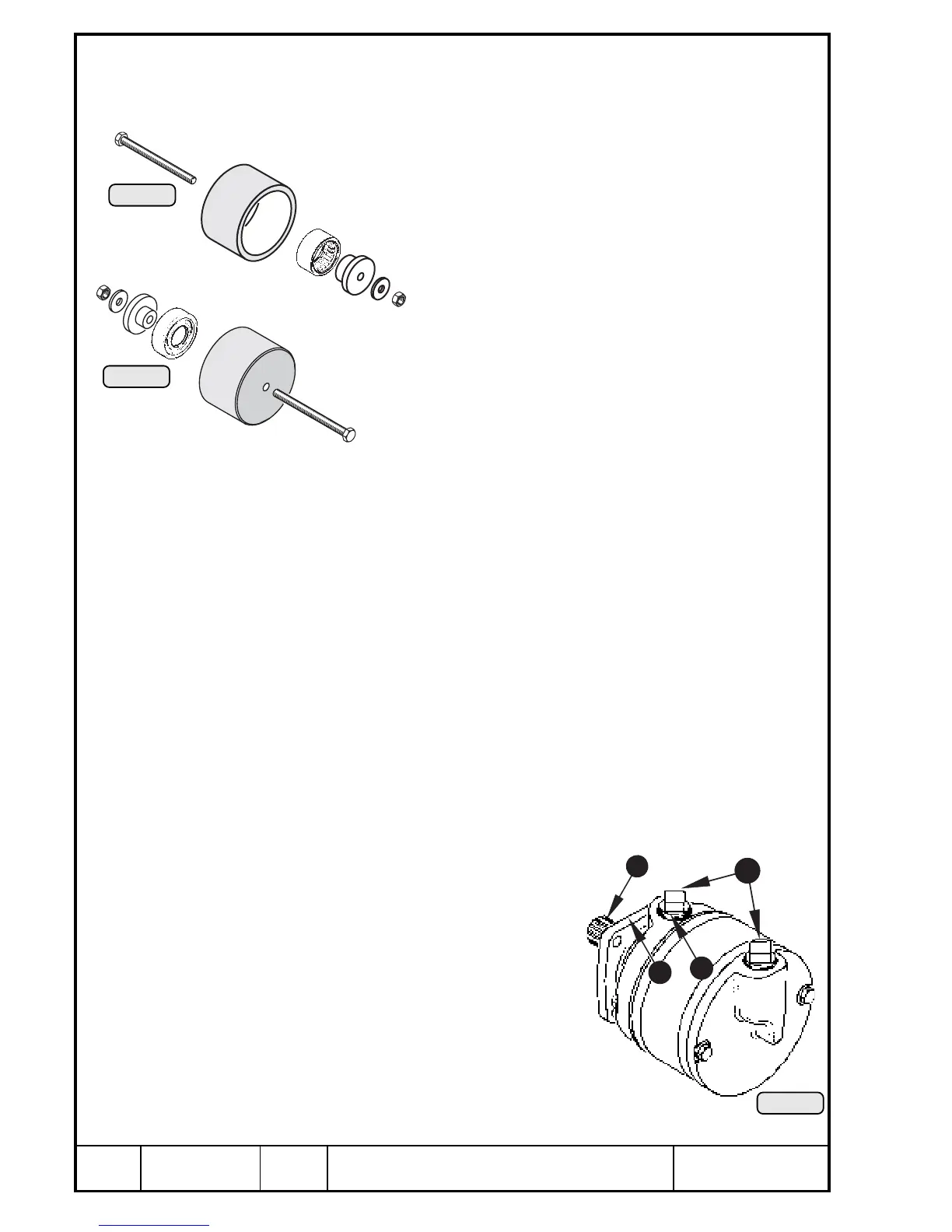

14.4.7) Vacuum pump

See Pic. 222.

The vacuum pump serves as drive of pneumatic inertial navigation instru-

ments.

◆ NOTE: The vacuum pump must not be taken apart and must be

renewed as complete unit, if necessary. Renewal during

overhaul at the latest.

Check teeth Q. Remove connections or plugs W from used vacuum pump. If

still in good condition they can be re-used. Renew damaged connections. For

fitting of hose connections, the pump can be clamped in a vice with drive

downward, using protective jaws.

■ ATTENTION: Only clamp on flange E. Never clamp the pump directly on

pump housing as this would damage the pump rotor. Never

install a pump that has been

dropped!

Spray connection threads R 3/8" NPT with

silicon and let dry. Do not use Teflon tape,

hose sealing lacquer or thread grease on the

connections. Only tighten connections with

ring- or socket wrench and bring them to

correct position. Retighten by max. 1,5 turn.

E

{

}

P

Pic. 220

q

P

}

w

W

Pic. 221

4

3

q

2

1

Pic. 222

00253

00254

00255

Loading...

Loading...