Reference

Modification no.

- 0 -

Page

256

Date

1997 02 01

Main

914 F

01480

14.9) Fitting of piston and cylinder assembly

14.9.1) Fitting of hydraulic valve tappets

Lubricate bearing bore for valve tappets in crankcase. Apply LOCTITE Anti-

Seize to the contact surfaces of the valve tappets, lubricate their outside and

insert them according to the recorded position

into the crankcase. The valve tappet must

be able to turn in the crankcase with-

out resistance.

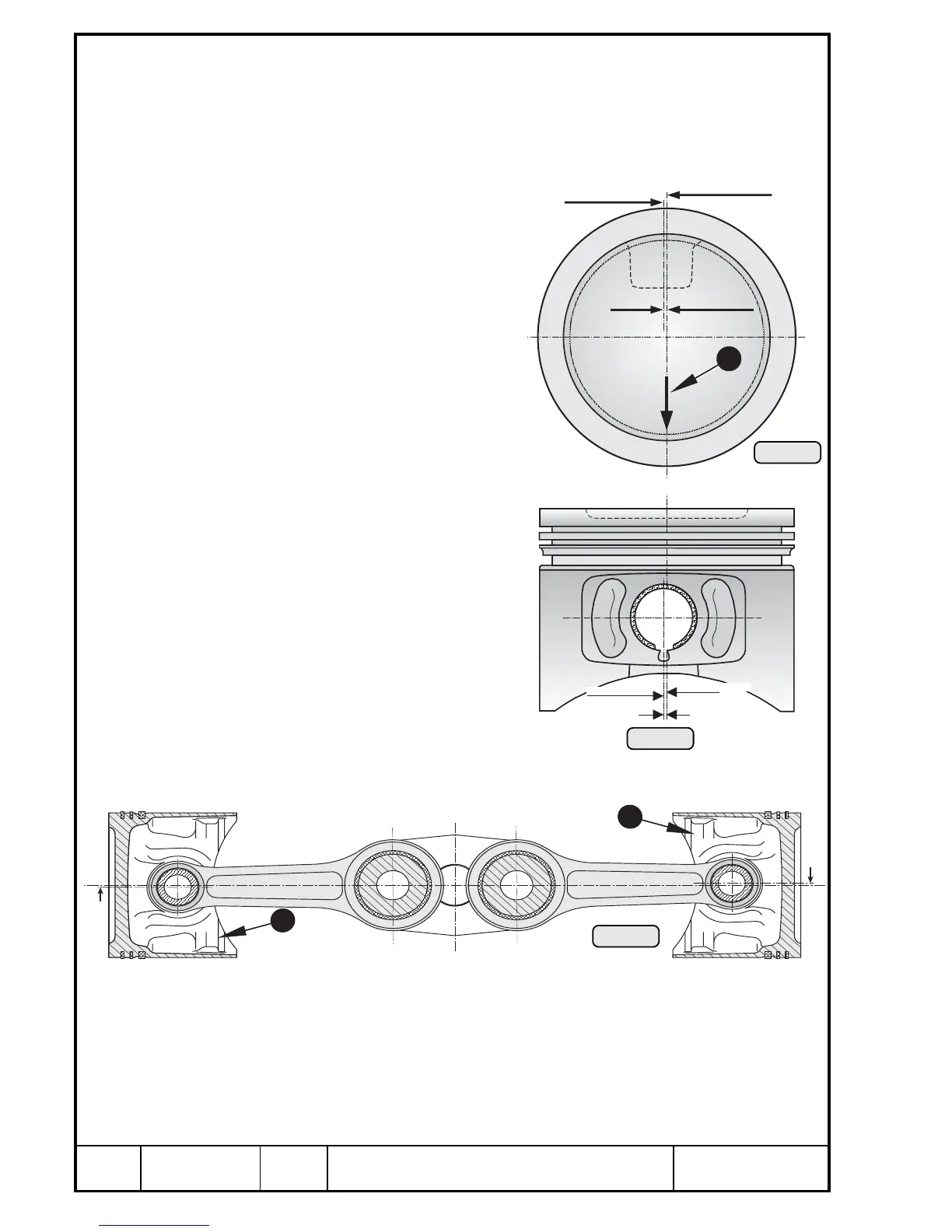

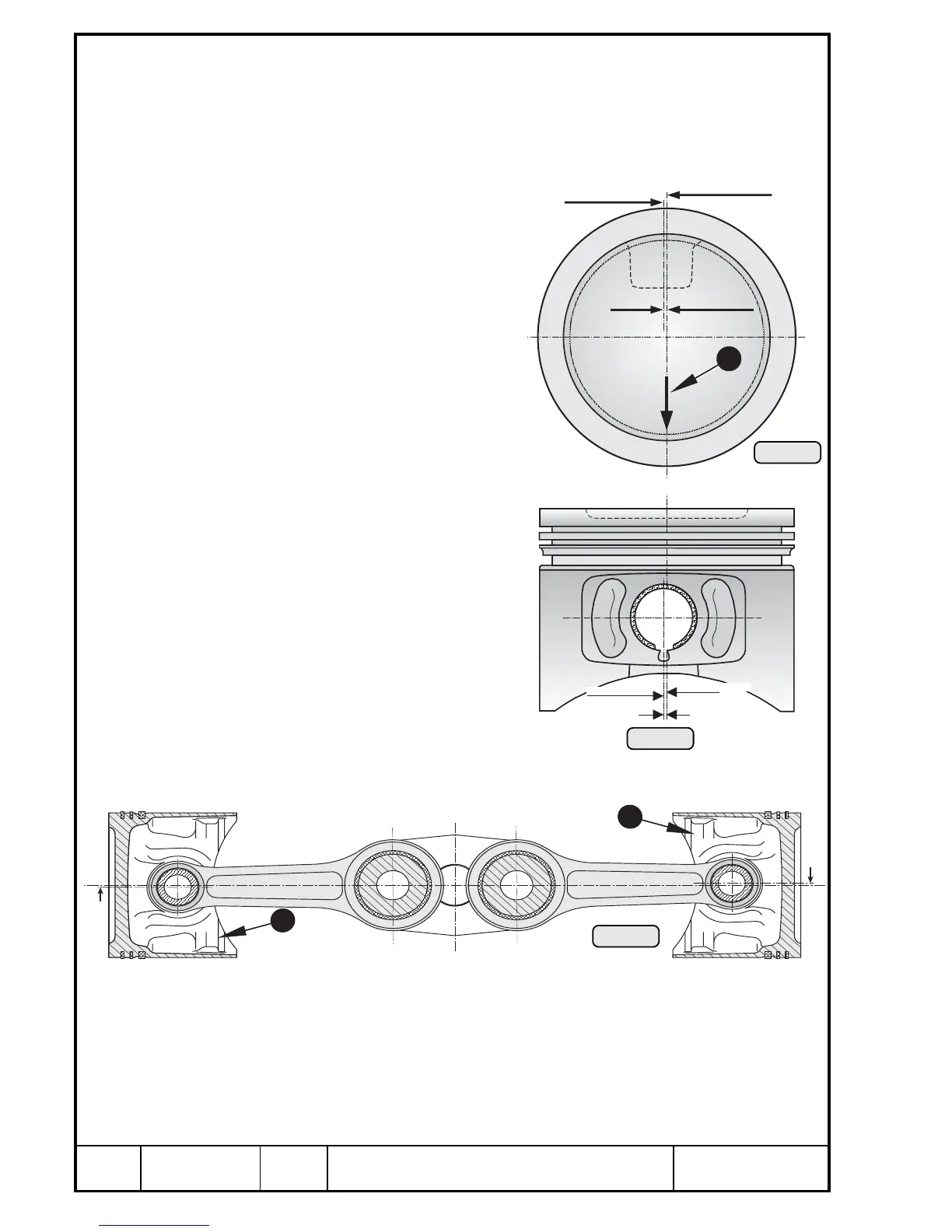

14.9.2) Fitting of pistons

See Pic. 268, 269, 270, 271, 272

and 273.

The piston pin centre is offset from

piston centre. At installation of the

pistons the arrow Q on the piston

crown has to point toward prop

shaft. Therefore on the pistons for

cylinder no. 1 and 3 the offsetting

(narrower side W) of piston faces

downwards, on cylinders 2 and 4

the offsetting (narrower side E)

faces upwards.

Install the piston as shown on Pic.

beside. The offsetting of piston pin

bore is 1 mm (.039 in.).

If the arrow Q on piston crown is

no more visible, the piston must be

measured.

1 mm

Kolbenachse

Bolzenachse

piston axis

pin axis

0,0394 in

1

piston centre

Nullhakenring /

circlip

Kolbenmitte /

1mm / 0,394 in

Bolzenmitte

pin centre

Loading...

Loading...