Reference Modification no.

- 0 -

Page

144

Date

1997 02 01

Main

914 F

01478

Check sealing faces of both oil pump housings and pump cover, plane on an

even plate if necessary.

Check pump shaft on the bearing seats I.

Remove plug screw O, spring P and ball {, clean and check ball seat }

in pump housing. The shim q is only fitted if required to reach specified oil

pressure.

Clean all parts and clear oil bores with compressed air.

Dimensions New Wear limit

See Chapter 15.

12

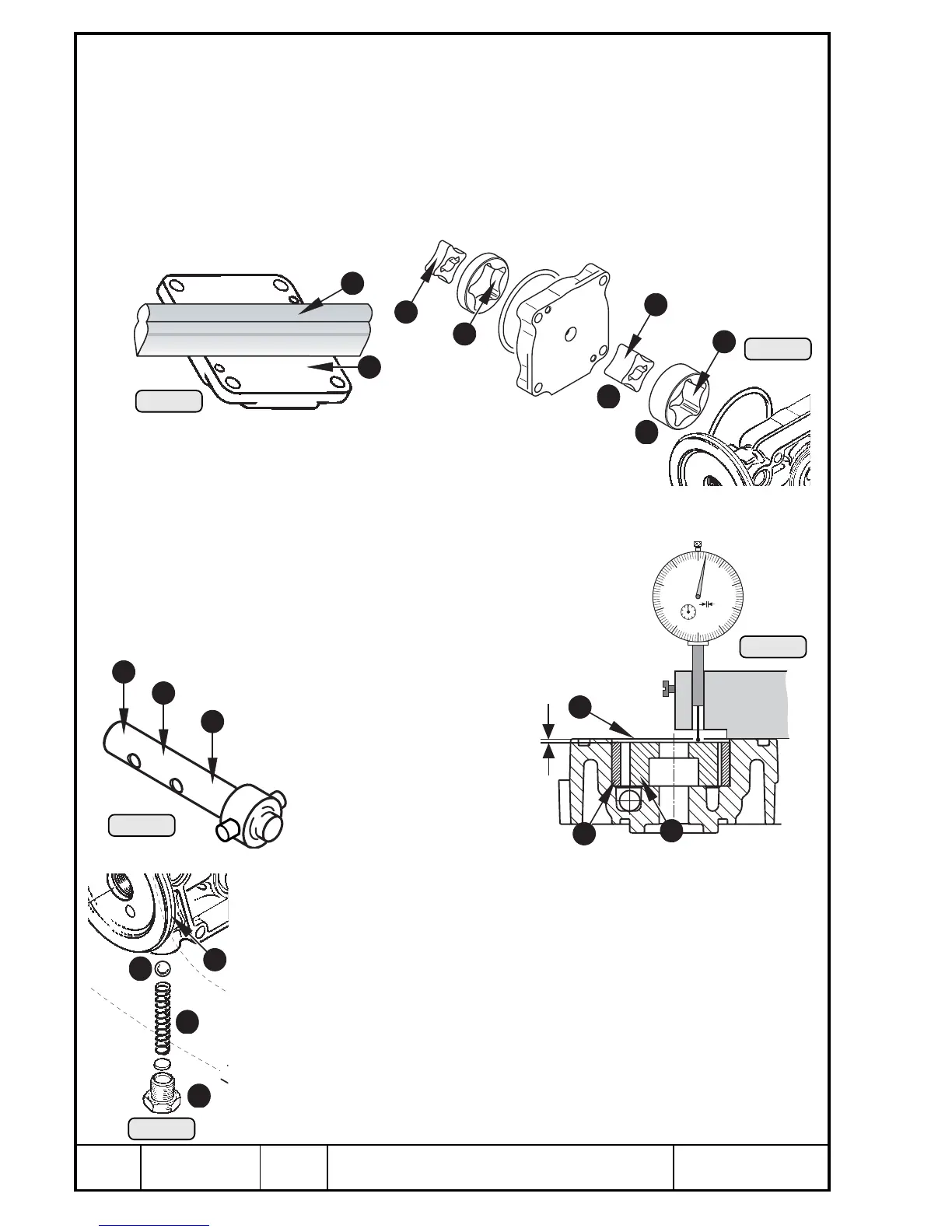

13.2.1.3) Oil pump checking

See Pic. 93/94/95/96 and 97.

Visually check all components of oil pump.

Check inside Q of oil pump cover with a straightedge W for wear.

Check all revolving pistons and rotors of pump. At noticeable furrows on

mating faces of rotor inside E and revolving piston outside R renew both

components.

2

1

Pic. 93

0

10

20

30

40

50

60

70

80

90

0.01mm

1

2

3

4

5

6

7

8

9

0

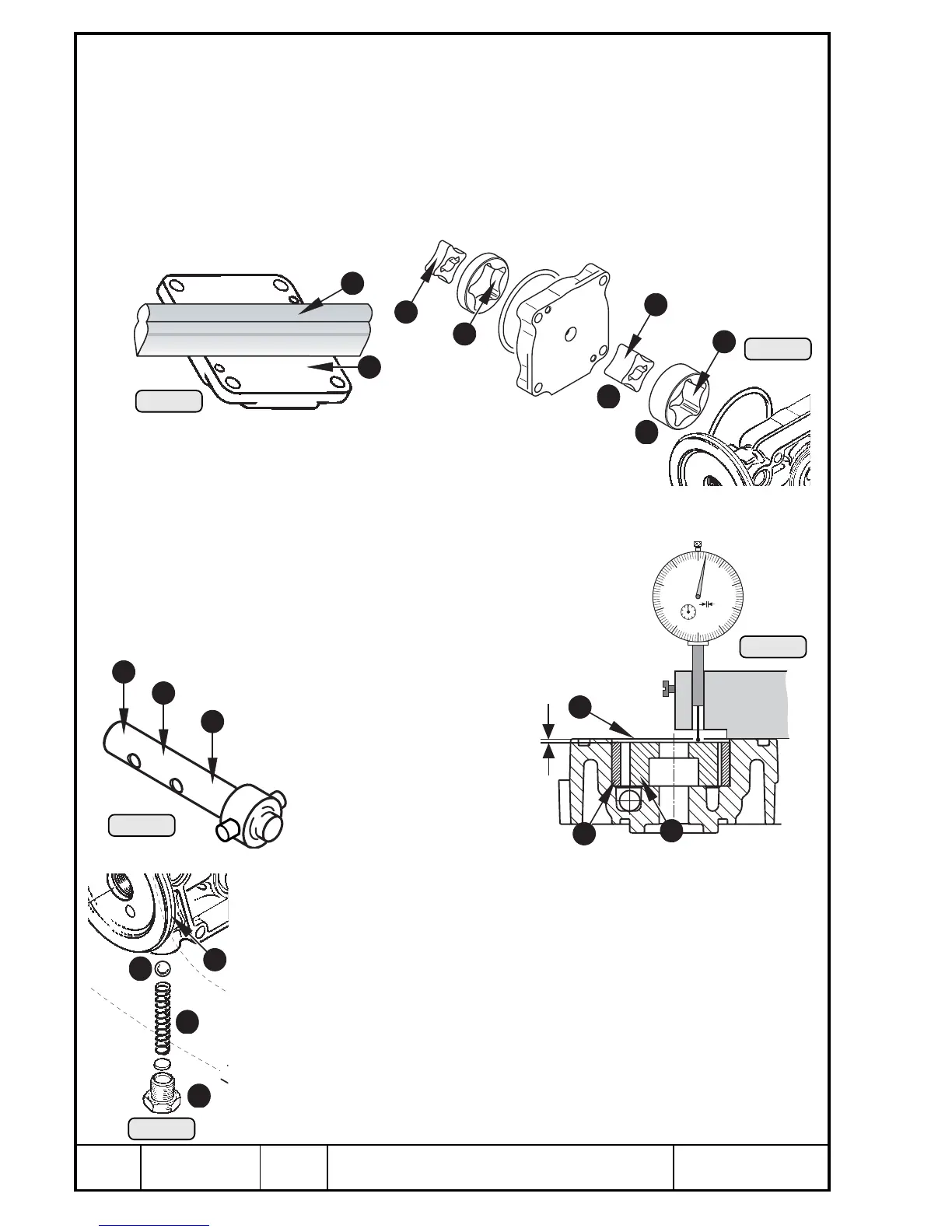

Pic. 96

W

00073

00074

00076

Pic. 94

Insert revolving pistons and rotors into their respective housings.

Check gap W (suction oil pump) between

crankcase flange surface — revolving piston

crankcase flange surface — pump rotor

Check gap W (main oil pump) between

crankcase flange surface T — revolving piston Y

crankcase flange surface T — pump rotor U

A bigger gap greatly reduces

pump capacity.

00076

Pic. 95

00071

Pic. 97

6

7

3

4

3

4

8

8

8

6

7

5

9

10

11

Loading...

Loading...