Reference

Modification no.

- 0 -

Page

80

Date

1997 02 01

Main

914 F

01476

11.8) Securing elements

See. Pic. 36

■ ATTENTION:Self-locking nuts, cotter pins, tab washers and safety wires must be

replaced each time they have been removed.

Respect without fail all additional indications regarding securing and sealing means

and lubrication of fixation elements. Adhere to specified tightening torques.

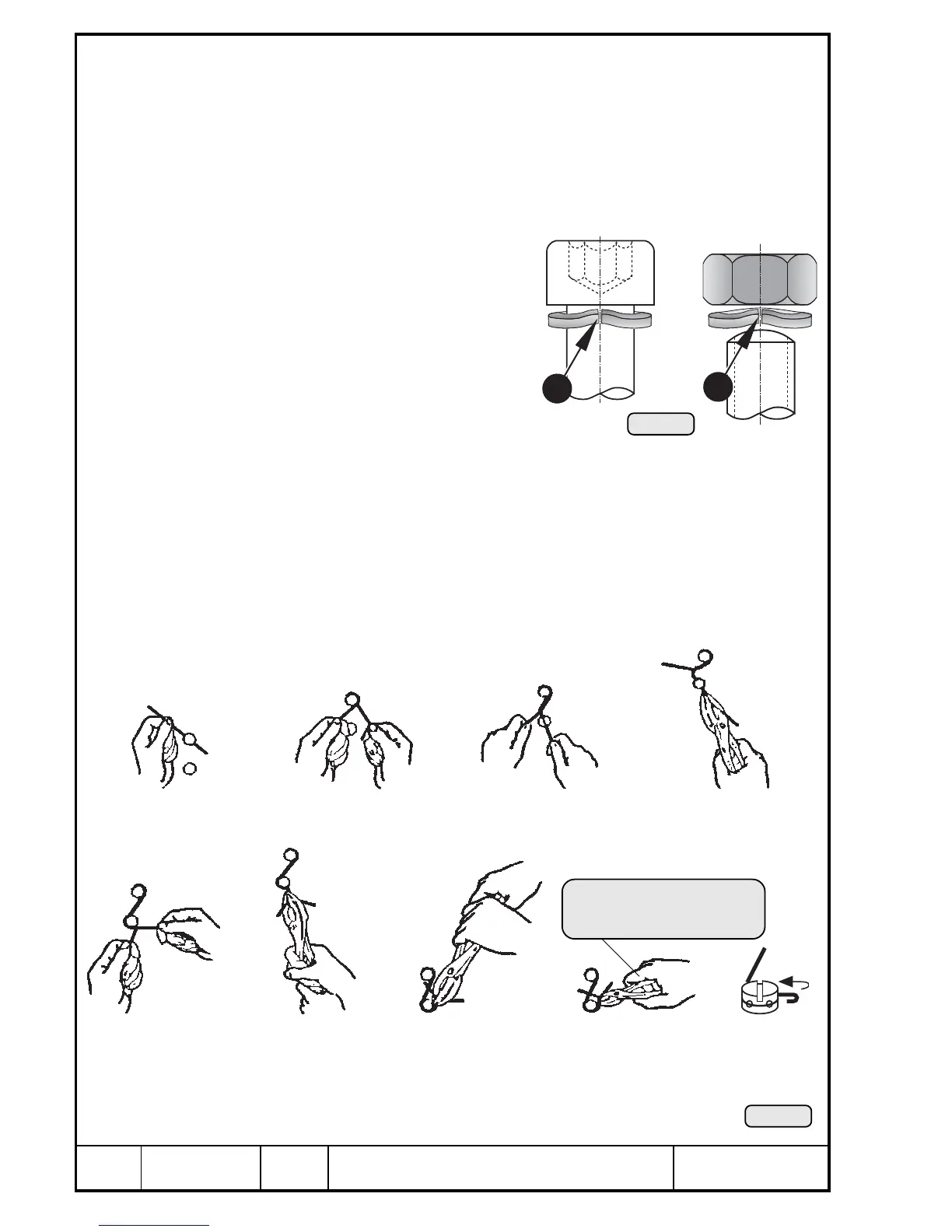

■ NOTE: Fit the lock washers with the

bent up ends Q facing the

screw head or nut.

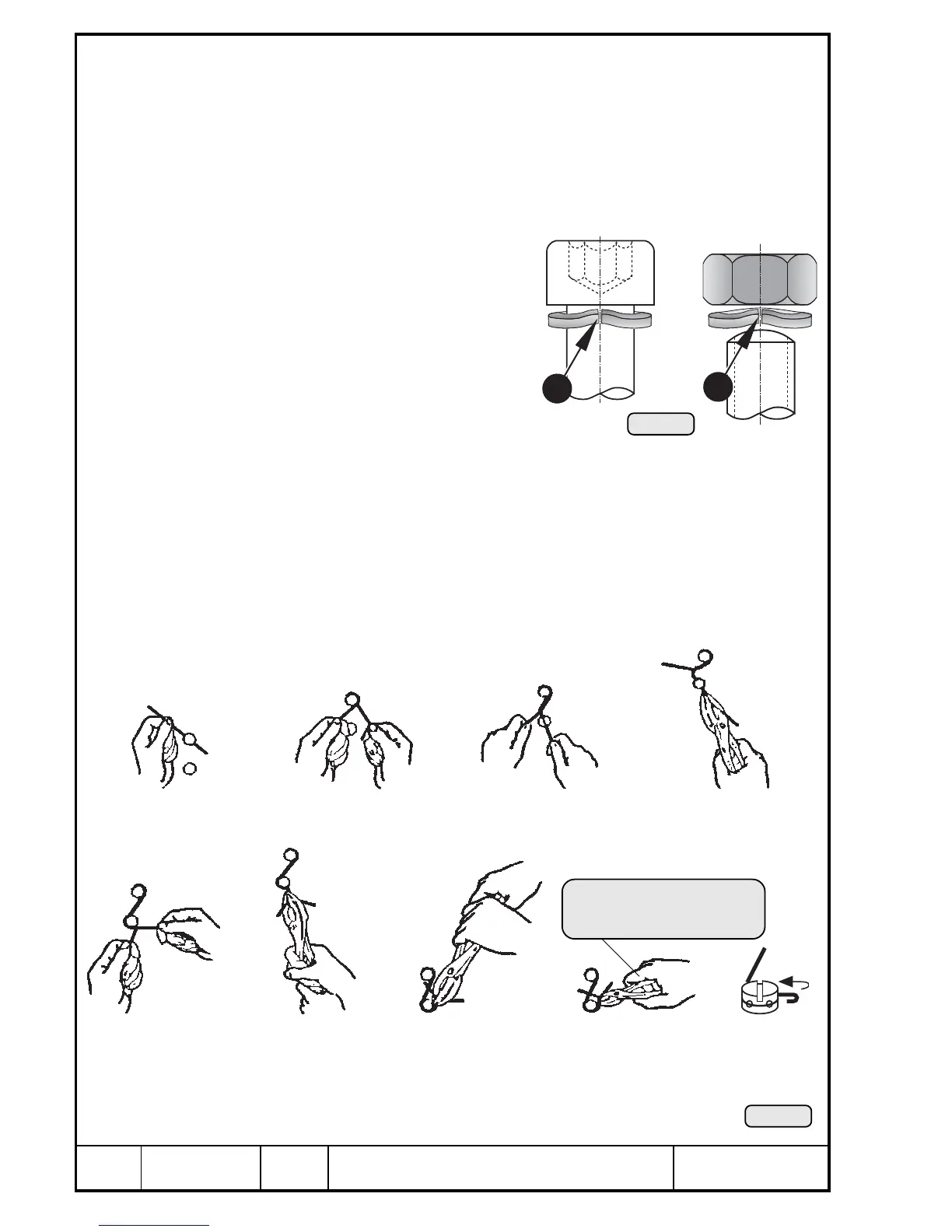

11.8.1) Wire securing

See Pic. 36 and 37.

Safety wiring serves to secure screws

or nuts to prevent unintended loosen-

ing. The screws or nuts are secured by

a 0,8 mm (.0315 in.) safety wire twisted

3 to 4 turns per 10 mm (.4 in.). The wire

must by no means be overstretched.

▲ WARNING: As a principle, all external engine components and acces-

sories must be wire-secured for safety reasons.

Turn twisted wire

end around screw

Stretch wires

and twist

approx. 4 times

Twist wire several times

up to next screw

Pass through

safety wire

Wind wire end around

the screw

Pass wire through and

stretch it with pliers

FINAL CHECK

Safety wiring between screws

must not be loose!

Bend wire end

and press it

towards screw

Cut off excess

length or wire

Twist wire around

the screw

1

1

Pic. 21

Pic. 37

00144

00145

Loading...

Loading...