Reference

Modification no.

- 0 -

Page

245

Date

1997 02 01

Main

914 F

01480

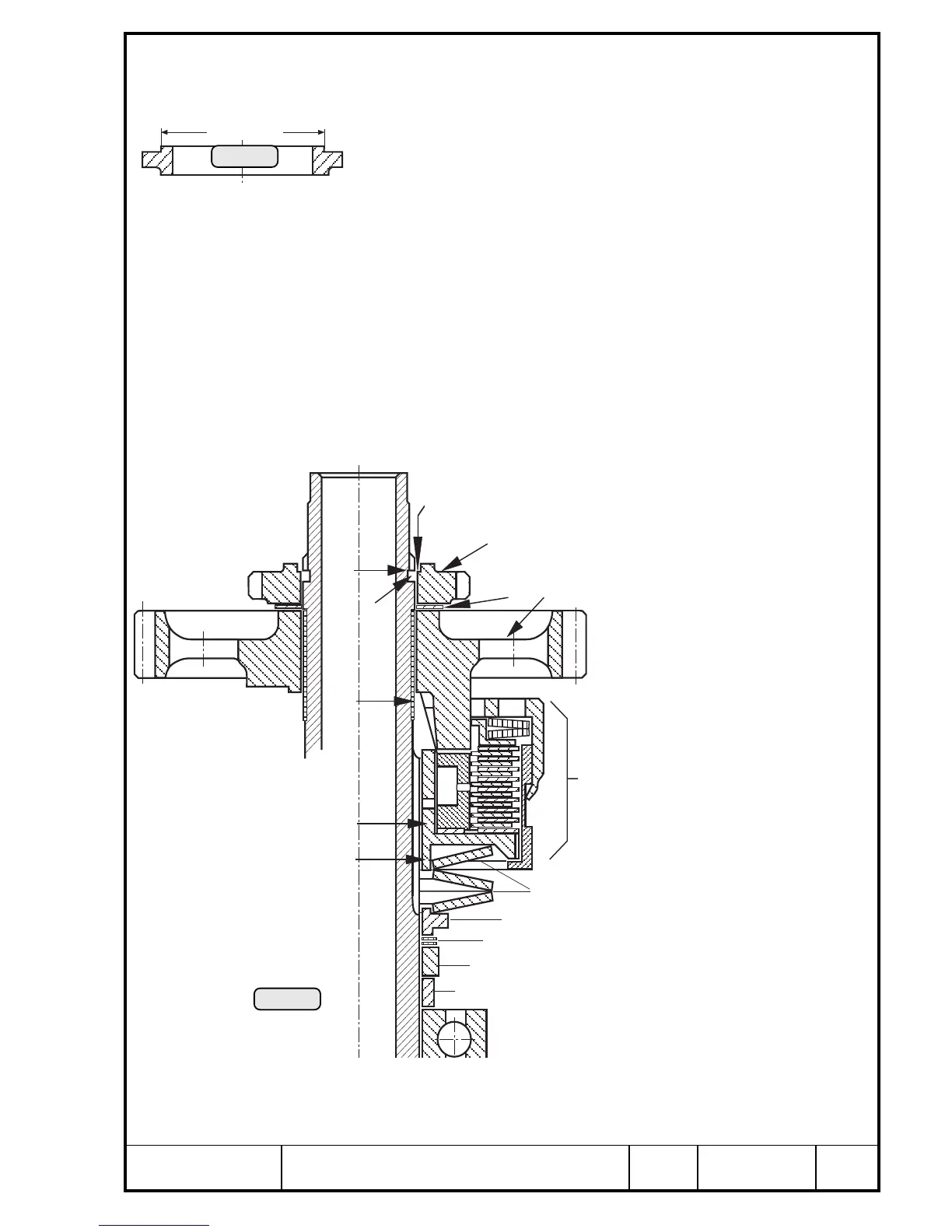

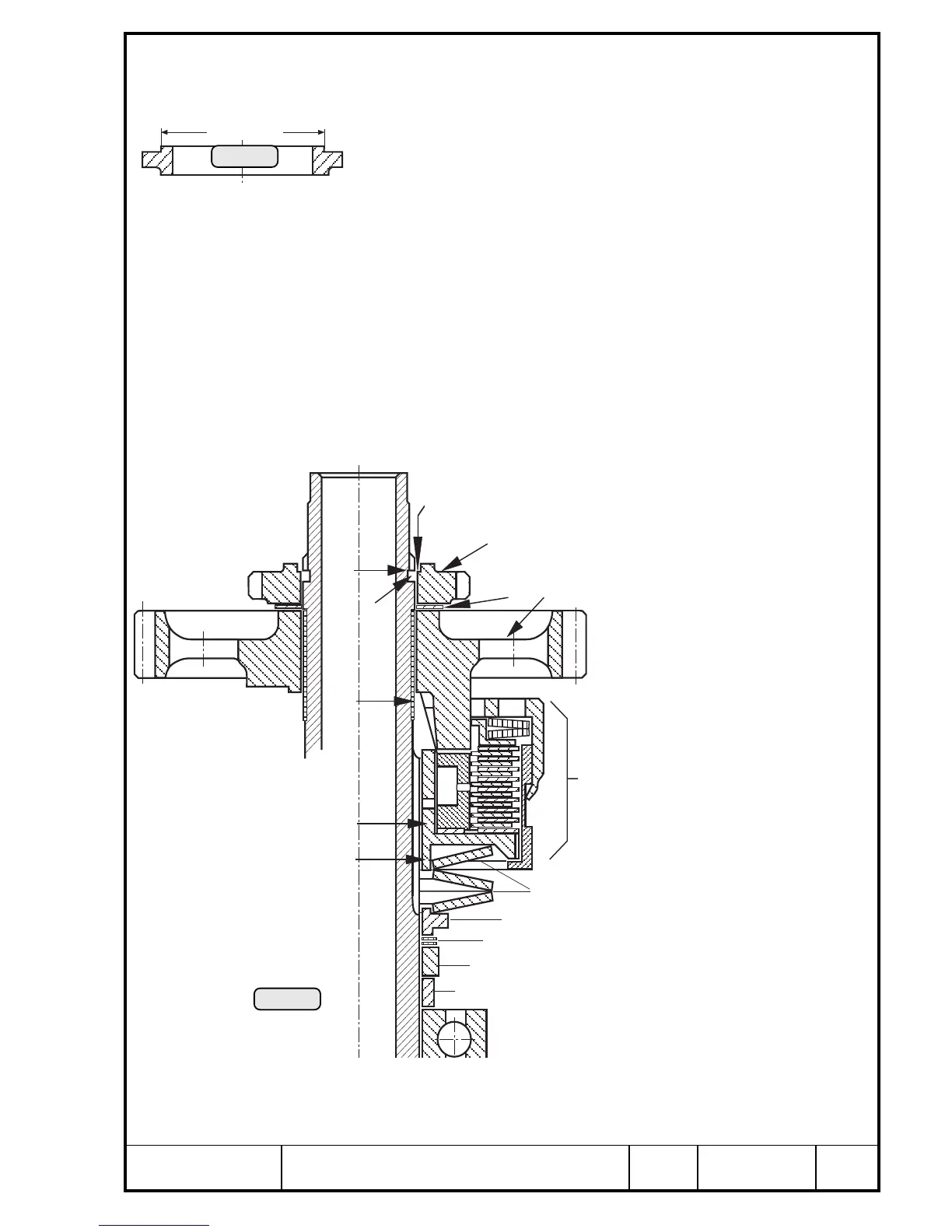

Turn gear cover. Next to fit are distance sleeve q 35,2/42/8 and eccenter w

for fuel pump. Then fit step collar e with dia. 40,8 mm towards disk spring, 2

disk springs r placed against each other and the 3

rd

disk spring t with it's

back to the previous disk spring. Take care that the disk springs rest

on the centering collar y of the hub. Apply LOCTITE Anti-Seize to

teeth of pre-assembled overload clutch u and slide into position on

propeller shaft. Carefully fit pre-oiled bearing bush i using circlip

pliers. Slide on dog gear o, plastic thrust washer p 33,2/51/1,2 coated on

both sides with LOCTITE Anti-Seize, and drive gear [.

■ ATTENTION: If the disk springs are not placed well centered, the dog gear

cannot be depressed sufficiently to allow inserting of ring

halves. Do not increase the pressure, but disassemble the

clutch again and center the disk springs more accurately.

◆ NOTE: Coat contact surfaces of disk springs and dogs as well as the

tooth profile of propeller shaft with LOCTITE Anti-Seize.

14.4.14)Adjustment of disk spring pre-tension

See Pic. 240 and 227.

With springs in the released state,

the face ] for the ring half must

be in line with the upper edge A

of the groove in propeller shaft.

Compensate the difference by

shims S placed without fail be-

tween eccenter w and step col-

lar e.

After pre-tensioning of disk

springs, depress gear o with

assembly ring, part no. 876 885,

until the ring halves can be in-

serted. Insert ring halves. Re-

lease disk springs (see also

Chapter 14.4.10).

■ ATTENTION:Never depress

springs flat, otherwise clutch

drum of overload clutch will dam-

age the gear cover. The ring

halves must be completely in-

serted in the groove on propeller

shaft!

Loading...

Loading...