Reference

Modification no.

- 0 -

Page

250

Date

1997 02 01

Main

914 F

01480

Maß

dim.

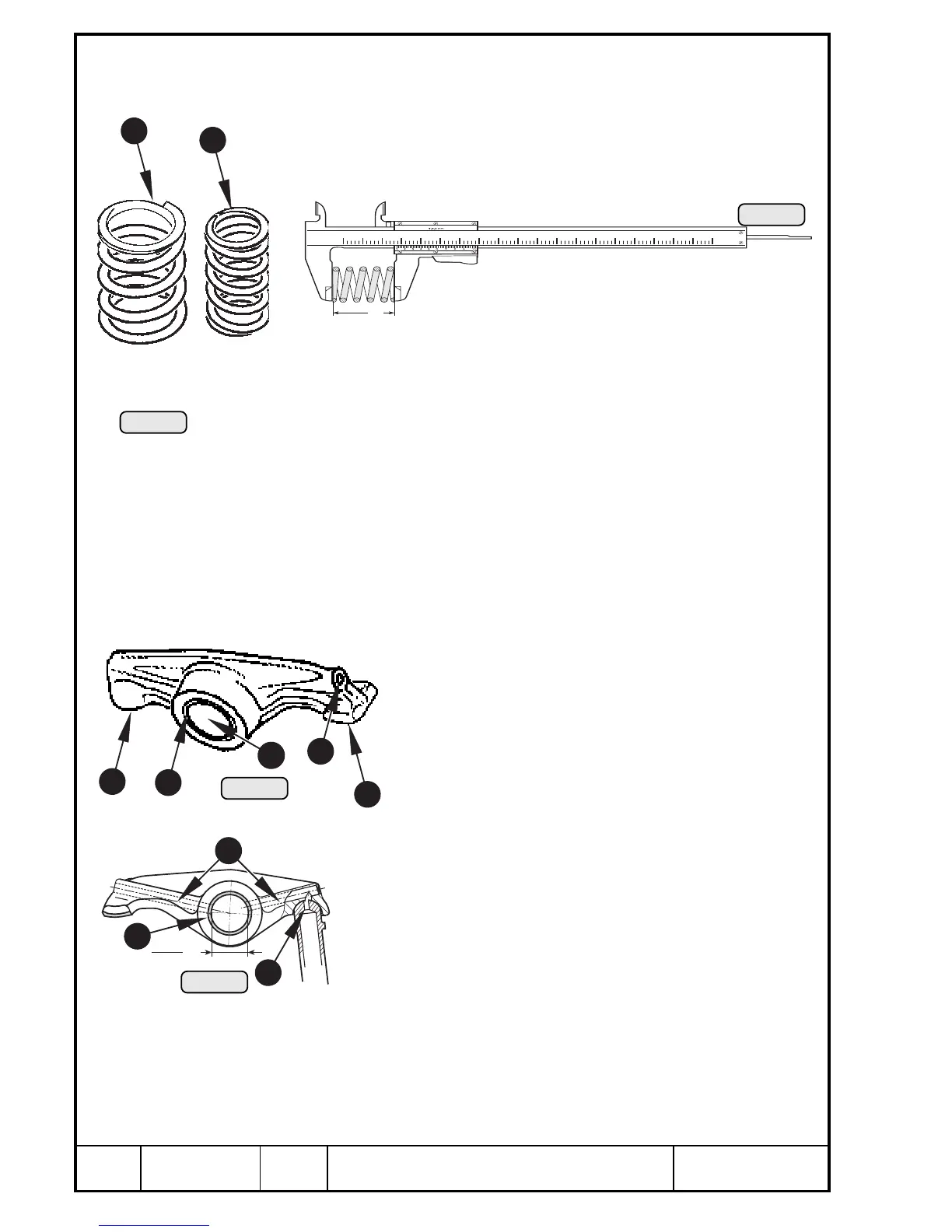

14.5.5) Valve springs

See Pic. 250 and 251.

2 springs per valve are fitted. The inner spring Q is of 2,3 mm thick wire, the

outer spring W is of 3,5 mm thick wire. The same springs are on inlet and

exhaust valves. Spring rate non-progressive. Visually check springs for

fracture and deformation.

Check free length of both springs, see dimension A in Chapter 15). Renew

valves shorter than the minimum length.

◆ NOTE: Actual spring length ought to be as equal as possible on

inlet- and outlet side. If need be, renew.

Dimensions new wear limit

See Wear Limits, Chapter 15).

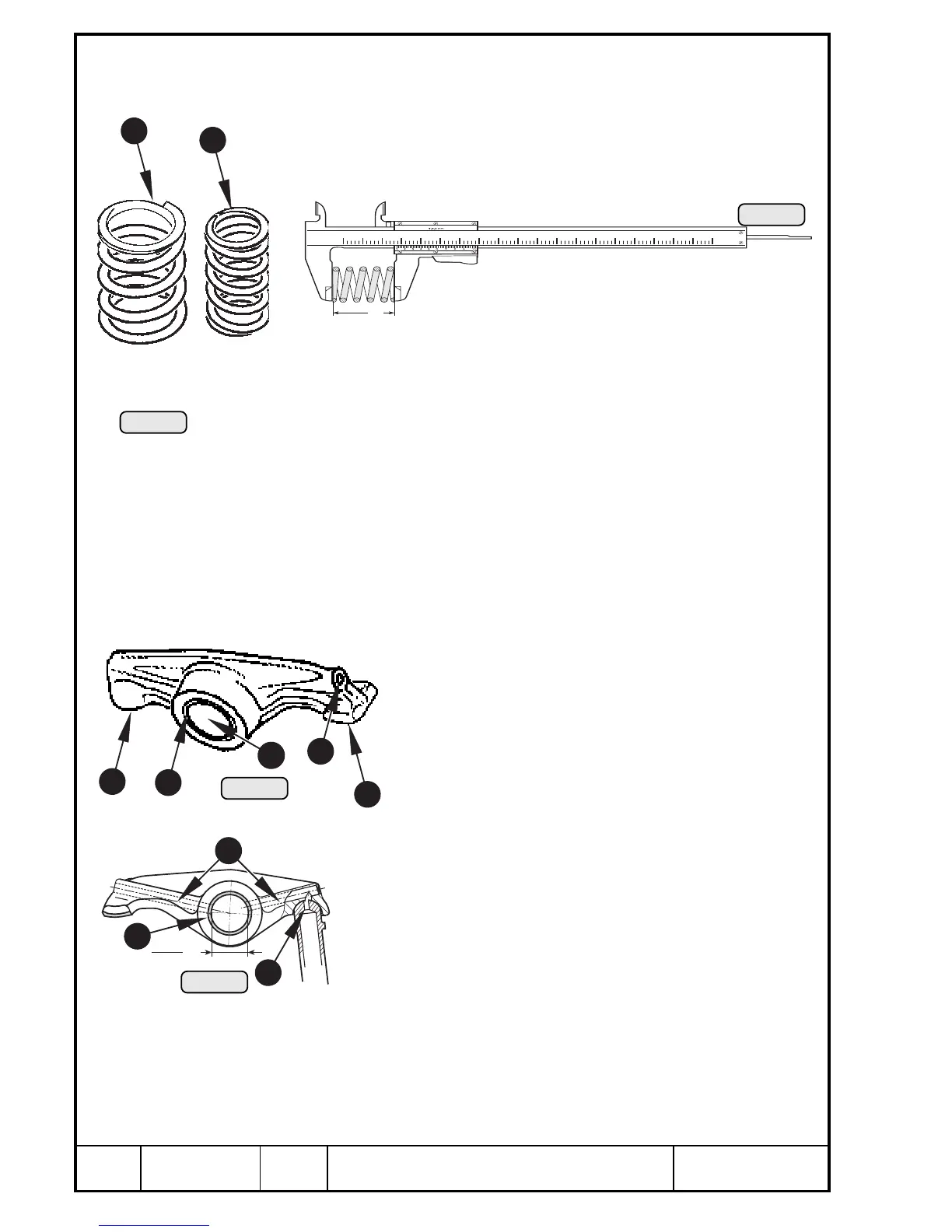

14.5.6) Rocker arms

See Pic. 252 and 253.

The rocker arm bearing surface Q is lubricated via the hollow push rod W to

the ball cup E. The oil flows through the bores R in the rocker arm. The oil

exit and in consequence the splash oil lubrication of the complete valve

mechanism is via bore T. The rocker arms for inlet and outlet

are different.

Check surface of rocker arm shaft and bearing bush Y for

wear. Visually check valve stem contact area U and ball

cup E of rocker arm. Excessive signs of wear indicate

lack of oil. Slight rework of contact area U on rocker arm

is allowed. Check oil bore R for free passage.

The bearing bush Y can be renewed. Knock out old

bearing bush with a suitable punch, clean both oil ducts R and

check for free passage with compressed air. Press in new bush

so that the oil ducts in rocker arm and bearing bush align. After

fitting of bearing bush, ream to dimension S, see Chapter 15).

Deburr bores and clean oil ducts with compressed air.

Dimension new wear limit

See Wear Limits, Chapter 15).

Pic. 251

1234567891011121314151617181920

Maß

dim.

1

2

1

5

3

6

Pic. 252

7

2

4

Pic. 253

6

Pic. 250

00283

00282

00286

00287

Loading...

Loading...