Reference

Modification no.

- 0 -

Page

244

Date

1997 02 01

Main

914 F

01480

16

14

15

17

18

Pic. 236

11

➪ Check teeth w of gear set.

➪ Inspect eccenter for fuel pump and

fuel pump plunger for wear, see

Chapter 13.1.7).

➪ Check step collar for wear in the

area of disk spring contact surface.

➪ Measure plastic thrust washer r

between dog gear { and drive gear

e, see dimension t in Chapter 15).

➪ Check dog gear bush t of hardened

steel for wear.

➪ Visually check ring halves y, renew as required.

➪ At visible wear of disk springs

u in the contact area i they

have to be renewed. Check

dimension y of the released

disk spring, see Chapter 15).

Dimensions of new

wear limit

See Wear Limits, Chapter 15).

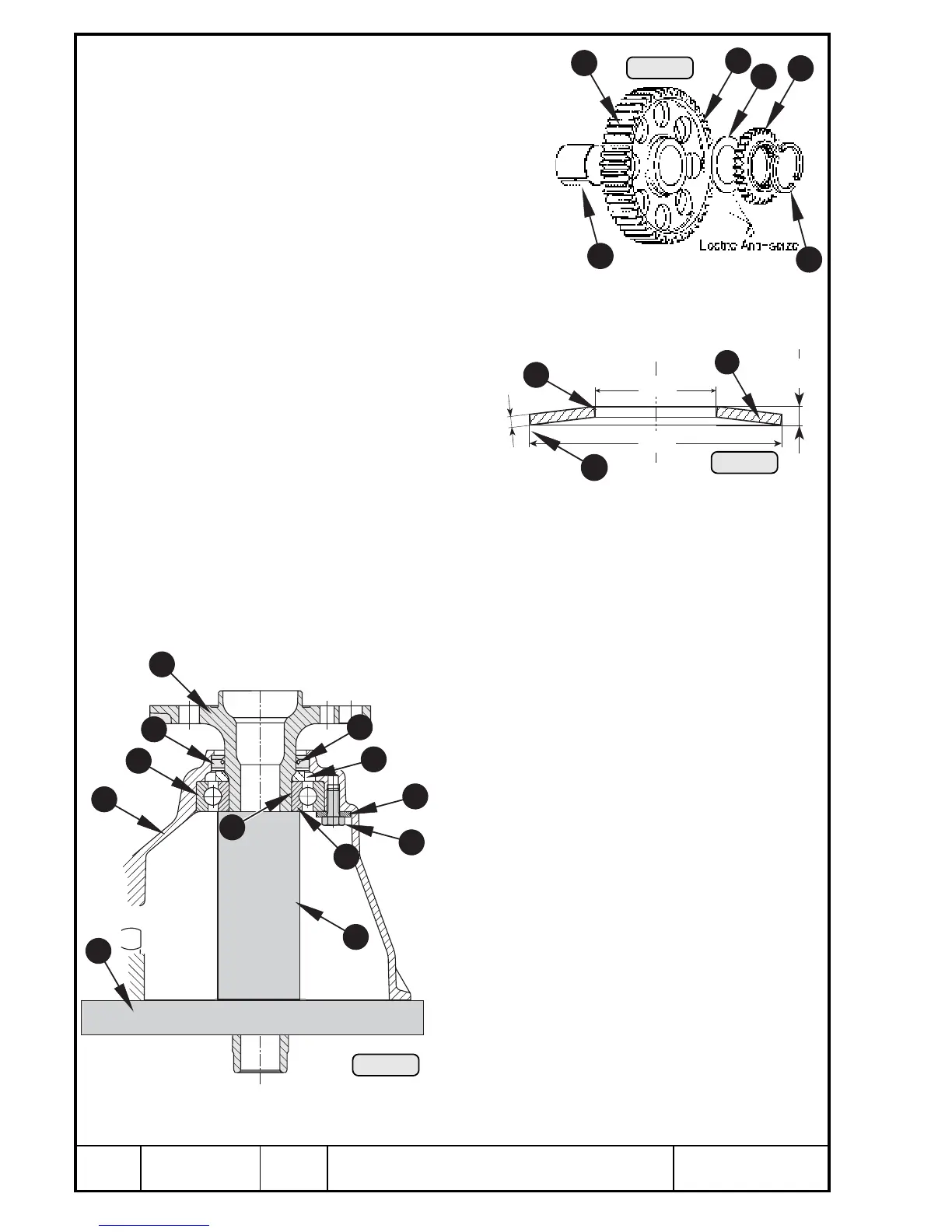

14.4.13) Gearbox — Re-assembly

See Pic. 238, 239 and 240.

Heat gear cover Q with hot air gun to approx. 100° C (215° F). Insert oil seal

W 40-55-7 from the inside, using punch, part no. 876 518, and grease sealing

lips E. Add distance ring R 36/50/5,5 with rounded side towards oil seal.

Press in ball bearing T, utilizing press-ring, part no. 877

320 and insertion punch, part no. 877 275. Fix bearing

in position, using 4 hardened washers Y 7,2/18,8/3

and hex. screws U M7x16.

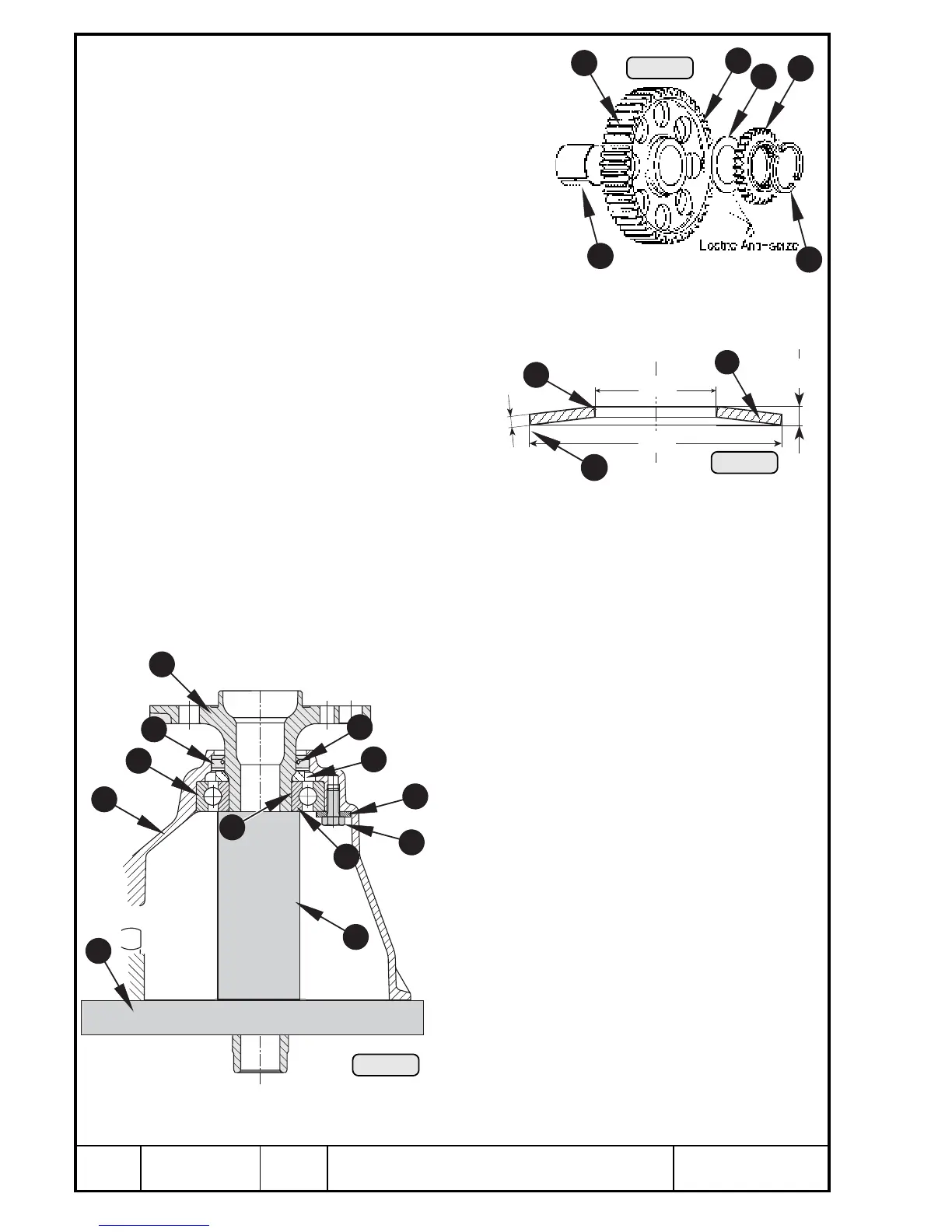

◆ NOTE: Secure screws with LOCTITE 221 and

tighten to 10 Nm (90 in.lb).

Place gear cover on a suitable plate I with a bore

for propeller shaft. Apply LOCTITE Anti-Seize to

bearing seat P 35 mm (1,4 in.) dia. and press

propeller shaft O carefully from outside into gear

cover.

■ ATTENTION: Do not tap!

Make absolutely sure to support the inner ring { of

the bearing with suitable tube }. It is an advan-

tage if gear cover is still warm at this stage.

9

2

5

1

3

4

6

7

8

10

11

12

Loading...

Loading...