Reference

Modification no.

- 0 -

Page

253

Date

1997 02 01

Main

914 F

01480

2

2

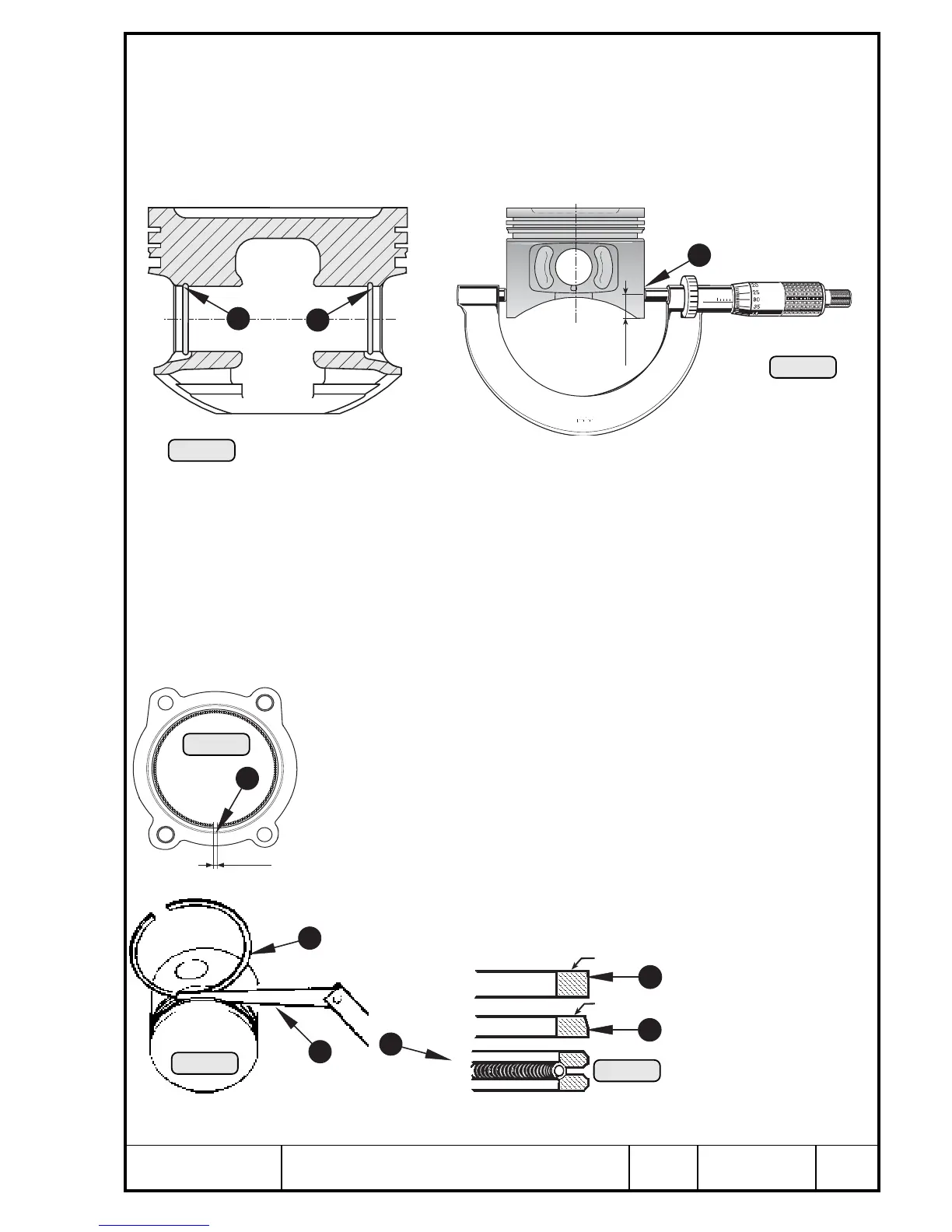

Visually check and measure piston. Piston and/or cylinder must be renewed

if piston to wall clearance exceeds 0,1 mm (.004 in.). To determine this

clearance, measure cylinder bore by internal caliper with dial gauge, to find

the biggest piston dia. use micrometer (most probably found at the position

Q depicted), see dimension D in Chapter 15).

Comparing the 2 dimensions — smallest cylinder dia. less biggest piston

skirt dia. — is the piston to cylinder wall.

Maß

dim.

Pic. 260

top

top

Kompressionsring/compression ring

Minutenring/bevel-edged ring

Ölabstreifring /

oil scraper ring

Pic. 261

5

5

1

2

3

Pic. 257

75

75—100 mm

1/100 mm

Maß

dim.

1

4

Pic. 259

Check the groove W for piston pin securing. At presence of a burr remove it

carefully. If the groove is excessively worn (> 0,3 mm = .012 in.), renew piston.

There are 2 tolerance groups, red and green (piston marked with a red or

green colour dot). Difference is 0,01 mm. The "red" piston is the smaller one.

Oversize pistons are not planned. The piston is supplied only complete with

3 rings.

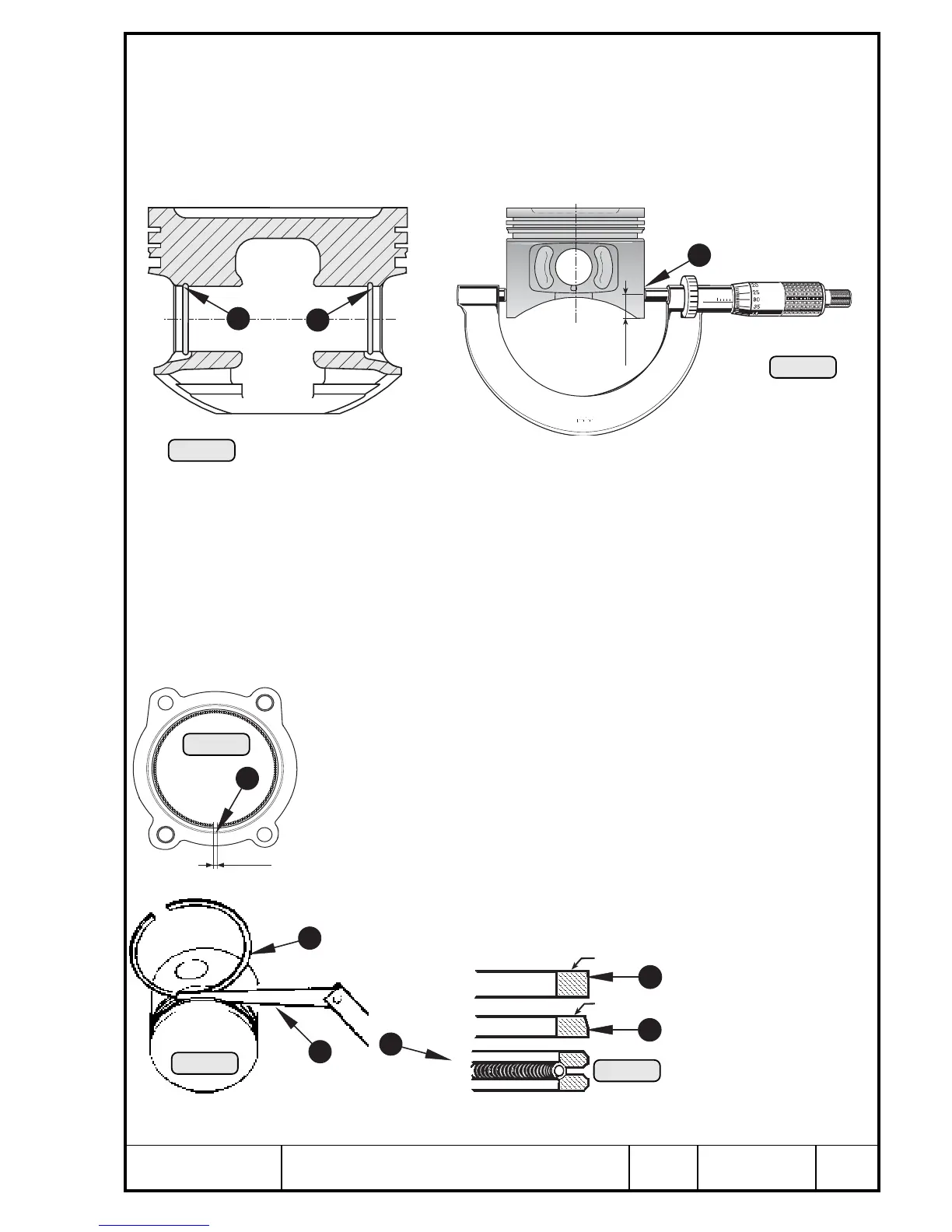

14.6.2) Piston ring checking

See Pic. 259, 260 and 261.

Check cleaned piston rings for correct end gap and flank clearance. With the

rings Q fitted on piston, measure flank clearance with a feeler gauge W.

Increased amount of residues in the spiral spring E of oil scraper ring

indicates use of AVGAS 100LL.

To determine ring end gap R, remove ring from the piston using piston ring

pliers, insert cleaned ring into a new cylinder. Use a piston as pusher to

align piston squarely in cylinder. Push ring down to approx. 10 mm (3/8 ")

from top rim of cylinder, measure ring end gap R by feeler gauge W, see

dimension F in Chapter 15).

At inspection of ring surface T the portion of surface contact can be seen

and indicates the wear.

Fit piston rings using piston ring pliers, with marking Y "TOP" or the dot mark

towards piston crown.

Pic. 258

00294

00292

00295

00296

00293

Loading...

Loading...