Reference

Modification no.

- 0 -

Page

230

Date

1997 02 01

Main

914 F

01480

Maß

dim.

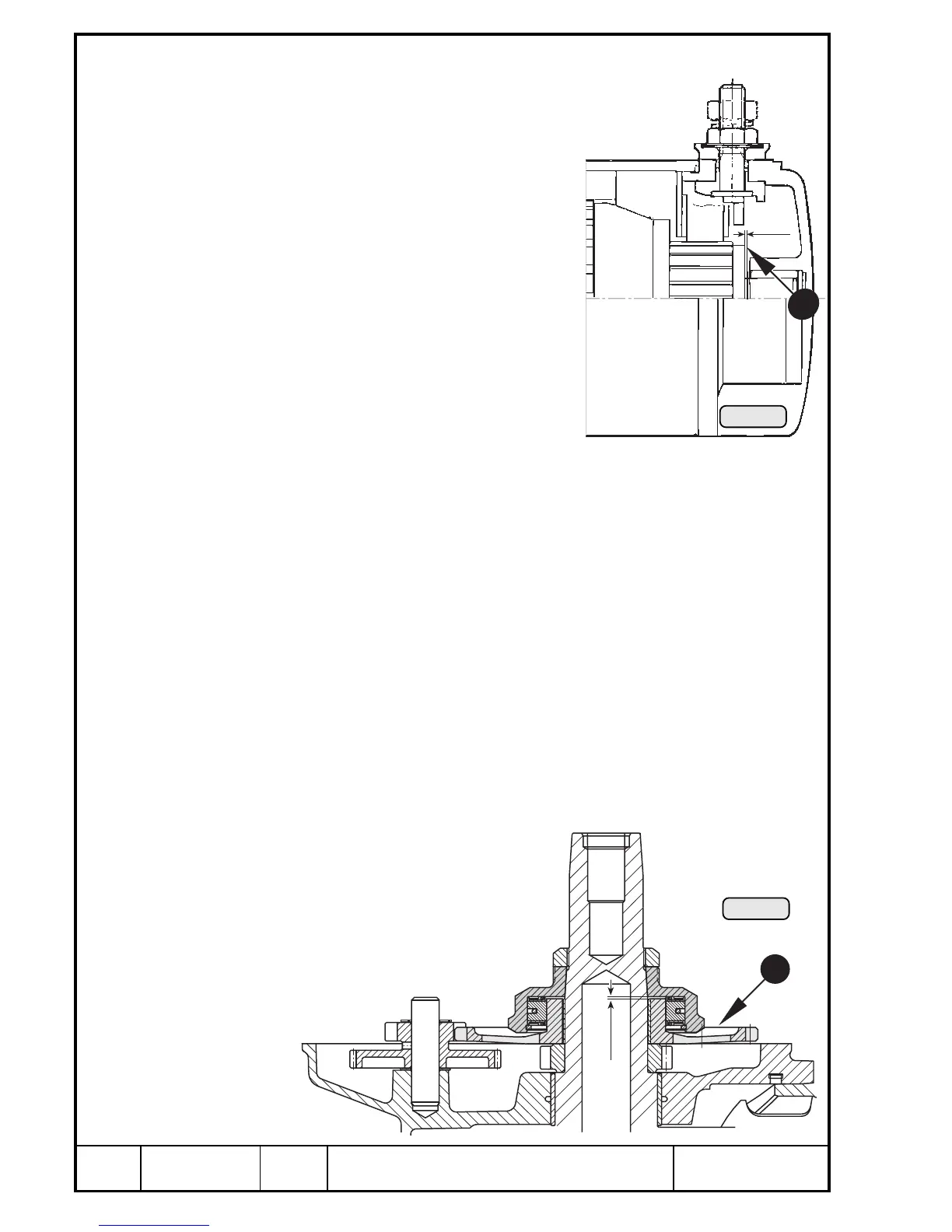

14.1.3) Electric starter — Re-assembly

See Pic. 197, 198 and 201.

Define the necessary number of shims Y to achieve the

axial clearance (see dimension 9 in Chapter 15) of the

armature T. Grease oil seal i, the ball

bearing P and bearing bush q. Insert

armature into the bearing support T, fit

new O-ring 62x1,5 and put starter housing

W over armature.

Install carbon brush holder R with springs.

Place the necessary number of shims Y

onto armature shaft and fit the complete

commutator support E with new O-ring

62x1,5 on starter housing.

◆ NOTE: Take care for correct positioning and

engagement of the positioning noses.

14.1.4) Electric starter — installation

See Pic. 204.

Grease bearing U slightly. Insert complete electric starter E with new O-

rings T 4,7x1,4 and distance sleeves R into the ignition housing Y.

◆ NOTE: Take care that the electric starter is not coming apart.

Tighten electric starter with lock washer A5 W and hex. nut M5 Q and fix

it with strap clamp 76 on ignition housing.

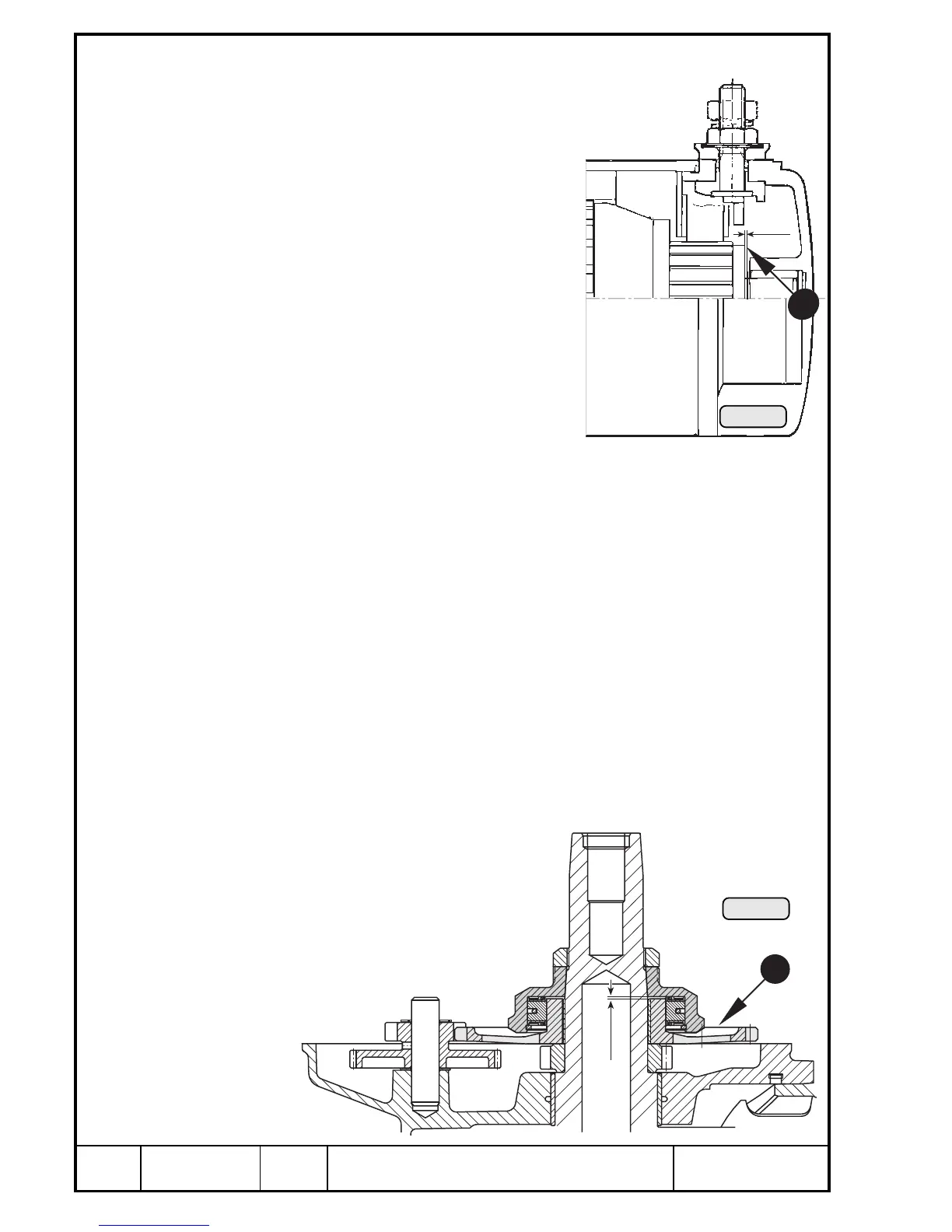

14.2) Sprag clutch

See Pic. 119 and 121.

After removal of flywheel hub and ignition housing, see chapter 13.3.3) and 13.3.4),

the sprag clutch can be removed. Withdraw idle gear shaft Q and idle gear W and

both thrust washers 12,5/21,5/1 E from both sides of the idle gear.

Check the axial clearance of the sprag clutch housing. It should be dimension P in

Chapter 15). At no or too little axial clearance the sprag clutch may not disengage

and the electric starter will be damaged.

Remove hex. nut R M34x 1,5 with socket

wrench 46 a/f, part no. 877 450, from crank-

shaft.

◆ NOTE: Hex. nut R with left hand

thread!

Maß

dim.

Pic. 201

6

6

Pic. 202

00235

00234

Loading...

Loading...