ReferenceModification no.

- 0 -

Page

129

Date

1997 02 01

Main

914 F

01478

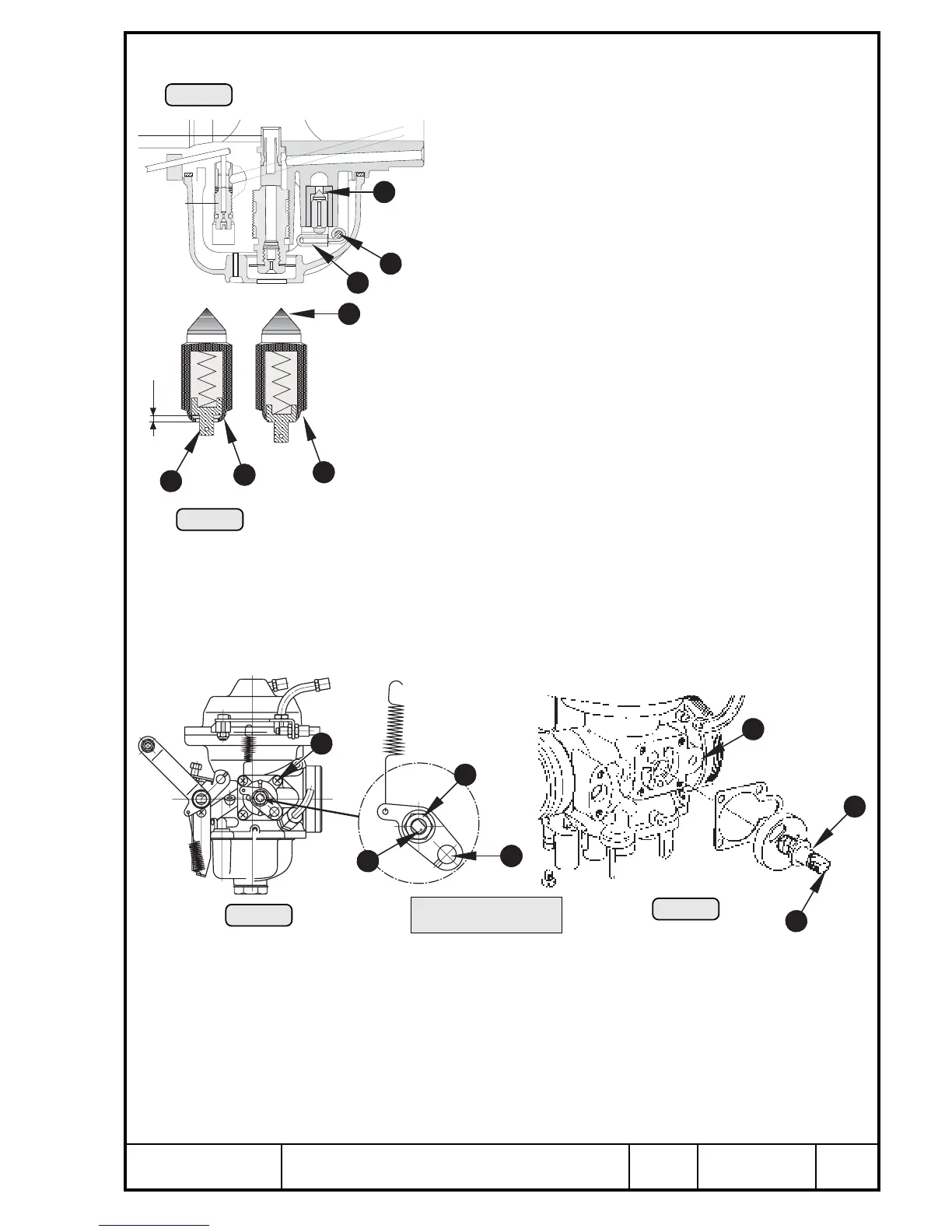

13.1.2.9) Check of float needle valve

See Pic. 70 and 71.

Drive out peg Q with a pin punch and remove float suspension W

and float needle.

Check float needle E and its seat for wear and the inlet

for contamination.

Check fuel inlet for free passage.

Inspect Viton tip R. At visible wear of the beaded edge T

at the sprung pin Y the valve has to be renewed. If the

distance becomes less than 0,5 mm (.02 in.) the float level

will be affected, leading even to interruption of the fuel

flow.

Insert float needle valve into the needle seat. Engage float needle

clip into float bracket, place it in position and fix float bracket with

pin.

Fit float chamber and fix it with plug screw Q and sealing ring 16/

22/1. Apply safety wiring.

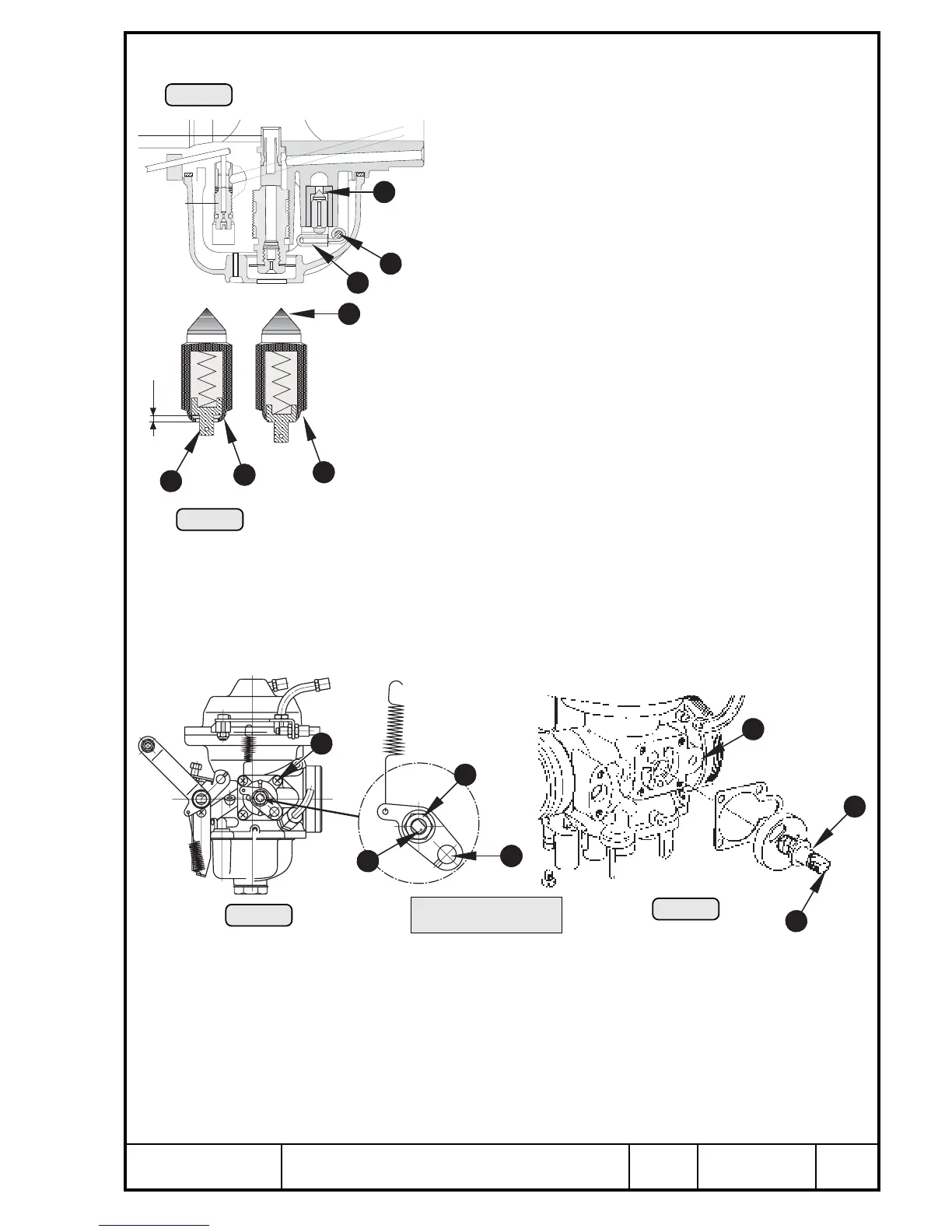

13.1.2.10) Starting carburetor (choke)

See Pic. 72 and 73.

Remove 4 countersunk screws Q M4x14 and remove the complete choke

housing. Remove hex. nut W and complete fuel choke valve from the

housing. Clean all parts and check.

◆ NOTE: The choke shaft E has a mark R. This mark has to point

towards cable engagement T or to bore Y.

00026

Pic. 71

3

2

1

Clean all parts and blow all bores and ducts with compressed air. Check all

parts and replace imperfect ones.

13.1.2.11) Carburetor reassembly

Reassembly of the carburetor with new O-rings and gaskets in reversed

sequence.

gut

good

schlech

Loading...

Loading...