Reference Modification no.

- 5 -

Page

162

Date

2003 03 01

Main

914 F

d03050

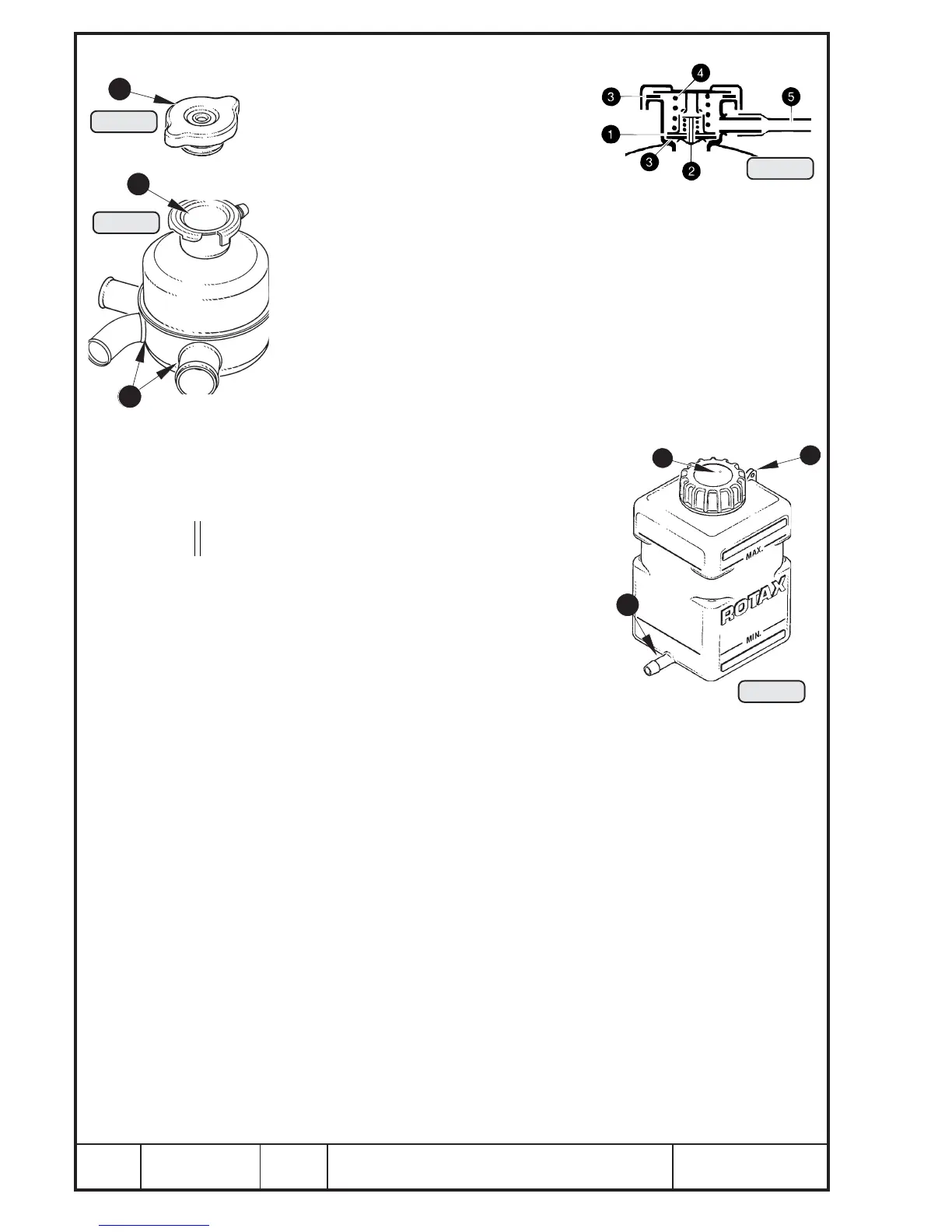

13.3.11) Expansion tank

See Pic. 125/126 and 127.

To allow pressure compensation in the cool-

ing system, an expansion tank is required.

When due to heating of the coolant the pres-

sure in the cooling system rises above 0,9 bar

(13 p.s.i.), the excess pressure valve Q opens and

the coolant can escape to the overflow bottle. When the liquid cools

down, the return valve W opens and the coolant is sucked back into the

expansion tank.

Check seal E, spring R and both valves of the radiator cap. If neces-

sary, replace radiator cap to assure 0,9 bar (13 p.s.i.) Y opening

pressure. T = connection to overflow bottle.

Check sealing surface U and hose connections I of the expansion

tank. Check for possible damages or chafing marks. A rubber plate is

glued to the bottom side of the expansion tank. Attach expansion tank

so that no scouring with neighbouring parts is possible.

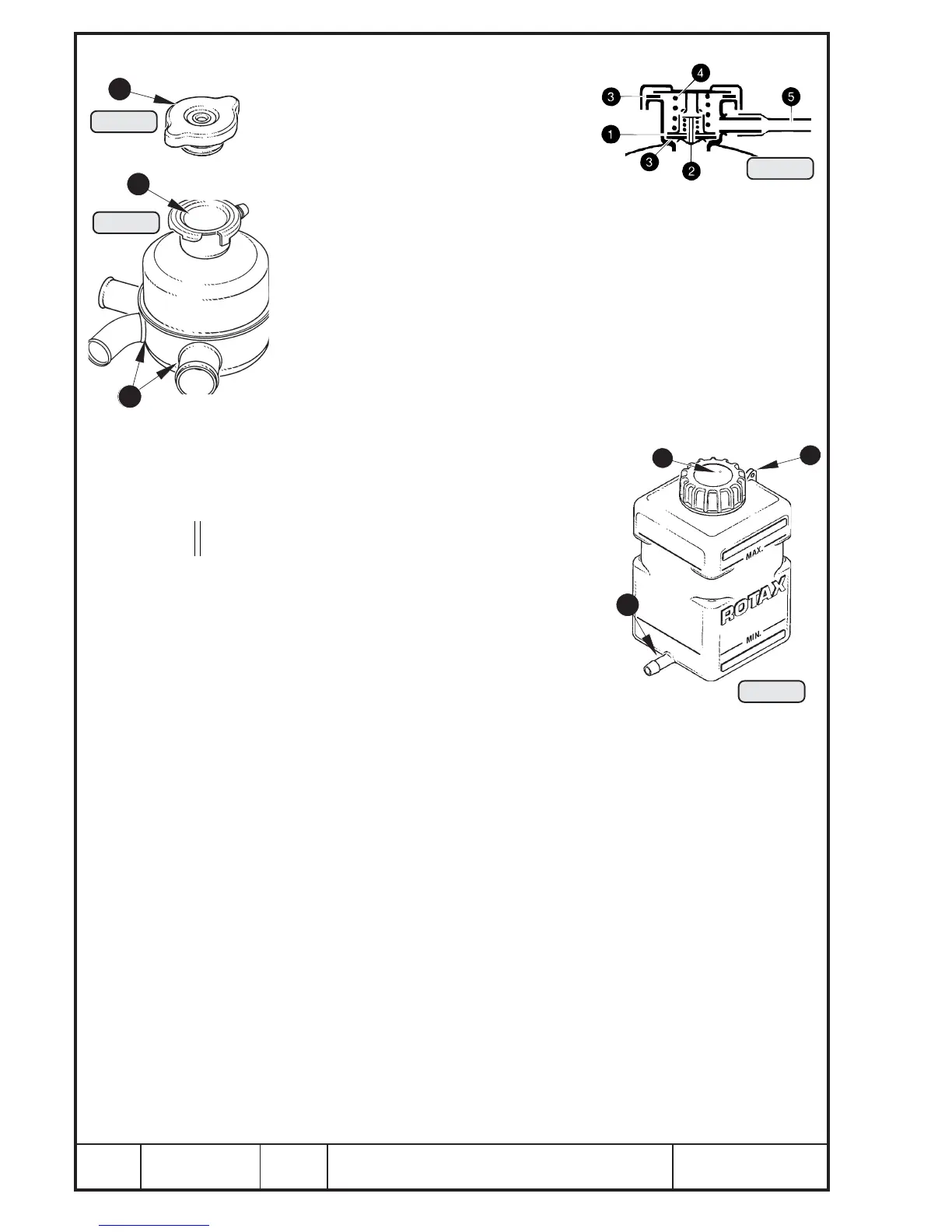

13.3.12) Overflow bottle

See Pic. 128

Check for damages. Check venting bore Q in the

cover (see Service Bulletin SB-914-025, “Modi-

fications or the overflow bottle”, current issue).

Check bracket W for the safety wiring. Check

tube connection E.

13.3.13) Radiator

Clean radiator elements and check for damages,

straighten if necessary. Especially check the

hose connections and the fixations. Check for

tightness if leaks are suspected.

13.3.14) Radiator hoses

Visually check for damages, especially in the area of the hose clamps. If

chafing spots are detected, replace coolant hose.

■■

■■

■ CAUTION: Only use temperature- and pressure resistant hoses meet-

ing the aeronautical standards.

13.3.15) Hose clamps

Visually check. Do not tighten hose clamps excessively to avoid damage to

the coolant hose. Position the lugs as to avoid collision and friction with

neighbouring parts.

13.3.16) Cooling air baffle

The cylinders are ram-air cooled. The cooling air is pushed at flight and by the

propeller into the engine compartment and is distributed by the air baffle

equally to the single cylinders. Visually check for damages, cracks, chafing

marks, burnt spots etc. At noticeable damages replace the air baffle.

3

1

2

Pic. 127

7

Pic. 126

0

,

9

b

a

r

8

Pic. 125

6

Pic. 128

00395

00393

00396

00394

Loading...

Loading...