RTC

®

5 PC Interface Board

Rev. 1.9 e

7 Basic Functions for Scan Head and Laser Control

102

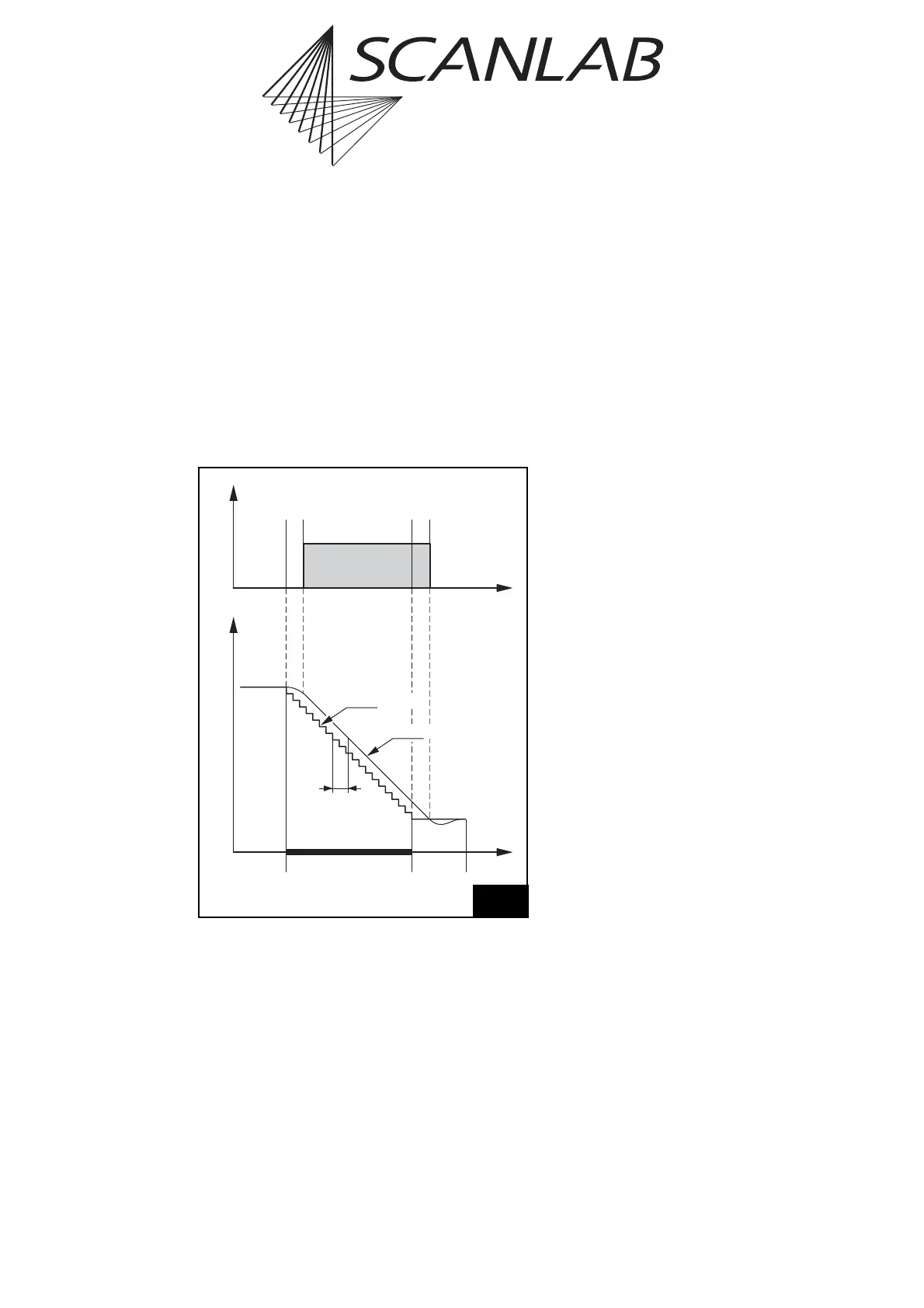

Mark Delay

Although the marking speed is usually lower than

the jump speed, a lag between the set position and

the real position occurs not only during a jump, but

also during a mark or arc command. Also a small

settling time can be necessary for the mirrors to reach

the set position.

To make sure that the scanners reach the final

set position properly before the next command

starts, the RTC

®

5 inserts a mark delay after a single

mark or arc command or after the last mark or arc

command of a polyline (see figure 32).

Notes

• If a mark or arc command is not followed by

further mark or arc commands, then a mark delay

will be inserted and the laser will be switched off

(after a LaserOff delay) (see figure 32).

• If a mark or arc command is directly followed by

a further mark or arc command, then a polygon

delay or a variable polygon delay will be inserted

instead of a mark delay (see figure 33 on

page 103 and figure 35 on page 105). The laser

will then remain on unless a correspondingly

smaller

edgelevel

was set with set_delay_mode

or set_delay_mode_list (see page 104).

• Mark or arc commands with a length of zero that

execute with switched-on “laser active” laser

control signals (i.e. within a polyline)

– are short list commands (if not timed for an

execution duration > 5 µs, see below). They

will not interrupt a polyline even when several

such commands directly follow each other.

– will be ignored in calculating delays (as of

RTC5OUT.out version 515): The mark delay or

(variable) polygon delay executes in accordance

with the commands that directly precede or fol-

low the zero-length command(s). If the com-

mand is executed individually (i.e. not within a

polyline), then no mark delay will be per-

formed.

– do not change the laser control signals (as of

RTC5OUT.out version 518): if the laser is still off,

then it won’t be switched on; likewise, if the

laser is already on, then it will remain on.

• But if a mark or arc command of zero length

executes with switched-off “laser active” laser

control signals (i.e. as a single command or at the

start of a polyline), then it will behave (as of

RTC5OUT.out Version 527) as a timed mark or arc

command with an execution time of 10 µs (see

following note).

• Timed mark or arc commands with zero spacial

length (as of RTC5OUT.out version 526 and if the

specified execution duration is > 5 µs) behave like

mark or arc commands of finite spacial length:

– If necessary, the laser control signals will be

switched on (at the beginning of a polyline)

and off (at the end of a polyline).

– Mark and polygon delays will execute (but vari-

able polygon delays are always 0).

– These commands will require at least a 10 µs

clock cycle for execution.

Notes on earlier versions

• With RTC5OUT.out version up to 514, only the

subsequent mark delay or (variable) polygon delay of a

zero-length mark or arc command is suppressed for a

zero-length mark or arc command; but the preceding

one is executed (a preceding (variable) polygon delay is

executed as a mark delay).

• With RTC5OUT.out version up to 517, the laser is

switched on after a LaserOn delay for zero-length mark

or arc commands (as is usual for mark or arc commands

with a length greater than 0).

Time

LaserPosition

Set Position

LaserOn

Delay

LaserOff

Delay

Mark

Command

Mark

Delay

Real Position

Tracking

Error

Scan head and laser control timing during a mark or arc command

with a mark delay. Grey shaded areas indicate that the laser is on.

Loading...

Loading...