RTC

®

5 PC Interface Board

Rev. 1.9 e

7 Basic Functions for Scan Head and Laser Control

96

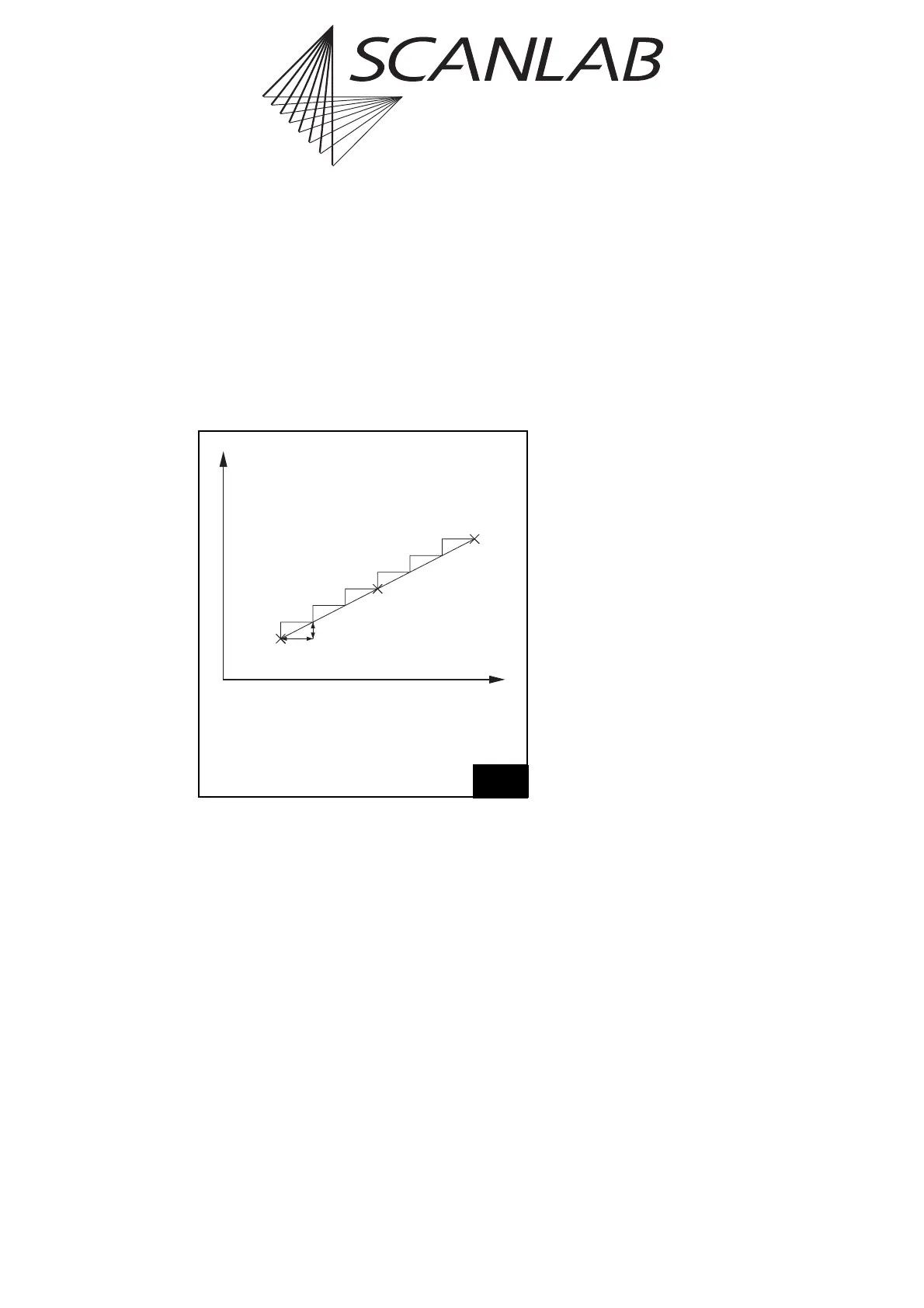

7.1.2 Microsteps

Each vector defined by a jump, mark or arc command

is divided into a number of small steps by the RTC

®

5.

These microsteps are transferred to the scan head at

a constant time rate (output period t). In controlling

its galvanometer scanners, the scan head implements

the steps via an analog servo loop.

Figure 29 shows how the X component of a vector is

divided into microsteps. The Y component is split up

in the same way.

The length s of each microstep is

s=v · t,

where v is the current jump speed (marking speed).

The output period t of the position update is usually

fixed at 10 µs. It is the same for 2D and for 3D appli-

cations. The output period cannot be set by the user.

Marking Time

The marking time consumed by any particular

marking process can be measured by calling the

command save_and_restart_timer (see page 397)

before and after the marking process. This command

saves the current value of the RTC

®

5’s integrated

timer and resets the timer value to 0. The measured

time can be read via the command get_time (see

page 286), which returns the timer value saved

during the most recent call of

save_and_restart_timer.

Notes

• You can implement direct execution of vectors

(without microvectorization) with the help of

microvector commands (see page 197).

•iDRIVE

®

scan systems let you execute jump and

goto_xy commands in either the (preconfigured

and microvectorized) vector mode or (after

enabling and activation) in jump mode (see

page 156).

•To compare RTC

®

5-internal

save_and_restart_timer time measurements to

external time measurements via the BUSY pin,

you should insert a list_nop between

save_and_restart_timer and set_end_of_list.

This ensures that any scanner delay will complete

before set_end_of_list. Without list_nop,

save_and_restart_timer includes the scanner

delay in its measurement even though it

completes only after set_end_of_list (and

therefore the BUSY pin is already low).

7.1.3 Marking Points

To mark a point outside of a polyline, you must switch

on the laser (i.e. the “laser active” laser control

signals) for the desired time period after a jump or

mark command (see laser_on_list,

laser_on_pulses_list, para_laser_on_pulses_list

and chapter 7.4 "Laser Control", page 128).

Outside or at the start of a polyline, you can also mark

a point (as of RTC5OUT.out version 527) by following

a jump command with a mark (or arc) command of

zero length (see page 102).

Within a polyline (as of RTC5OUT.out version 526),

points can also be marked by incorporating into the

polyline a timed vector or arc command with a zero

vector or arc length (see page 198).

t

x

Dt

Dx

(t

0

| x

0

)

(t

1

| x

1

)

(t

0

+i·Dt | x

0

+i·Dx)

29

x

0

X coordinate of the current output

position before scanning the vector

x

1

X coordinate of the end position

of the vector

t step period (10 µs)

The X component of a vector is split up into microsteps.

Loading...

Loading...