RTC

®

5 PC Interface Board

Rev. 1.9 e

8 Advanced Functions for Scan Head and Laser Control

161

8.1.9 Fault Diagnosis and Func-

tional Test

If a problem occurs, the versatile status return func-

tions of the iDRIVE

®

scan system can be used for scan

system diagnosis, too. These functions allow to read

for instance

• the current operating state

• the operating state at the moment of the most

recently occurred operation interruption and

• an event code, indicating which particular event

caused the scan head to enter a temporary or

permanent error state.

To verify that data transfer capability between the

RTC

®

5 and a scan system is intact,

control_command can transmit an 8-bit value –

separately for each axis– to the scan system. Subse-

quently, a 20-bit value will be returned on the corre-

sponding status channel: If data transfer is error-free,

then the upper 8 bits of the returned 20-bit value will

be identical with the originally sent 8-bit value, and

the next lower 8 bits will be identical with the

complement of the sent 8-bit value.

These 20-bit values will be returned until the

control_command is used to select another return

data type (see section "Configuring Status Return

Behavior" on page 153).

To facilitate – after a data transfer verification – resto-

ration of the status return behavior in effect prior to

the data transfer verification, the control_command

allows the prior data type to be temporarily stored for

later retrieval.

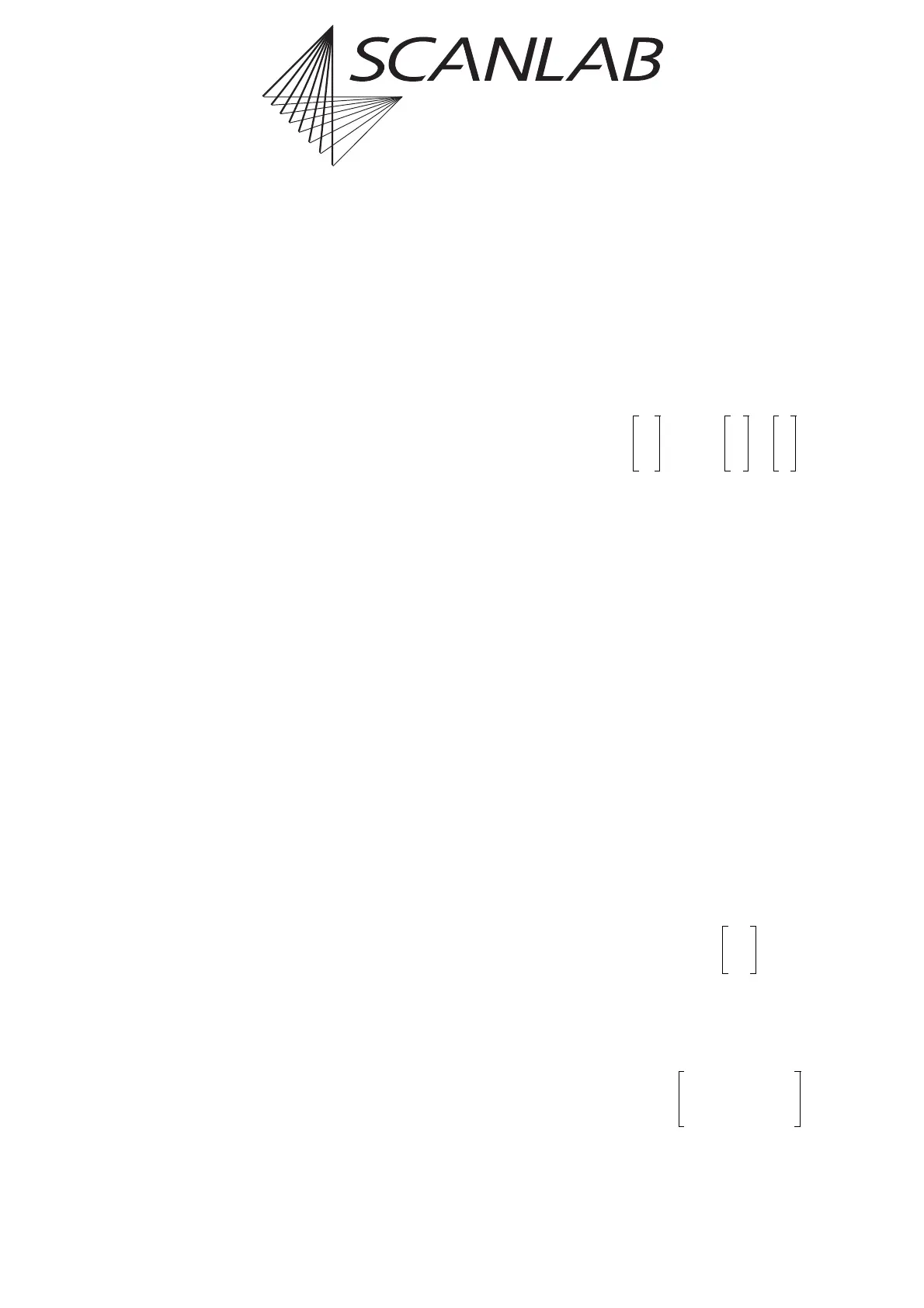

8.2 Coordinate Transformations

For precise set-up of the scan system relative to the

image field (if the “second scan head control” option

has been enabled, two scan heads can be adjusted

relative to a common image field), a linear coordinate

transformation can be defined (separately for the

primary and secondary scan head connectors) for all

X and Y output coordinates (x|y) defined by vector or

arc commands:

The (2 x 2) total matrix M is thereby automatically

calculated by the RTC

®

5 as a product of a scaling

matrix M

S

, a rotation matrix M

R

and a general trans-

formation matrix M

T

:

The coefficients of the three matrices (M

S

, M

R

and

M

T

) and the offset values (x

0

|y

0

) can be individually

defined for the primary and secondary scan head

connector.

The offset (x

0

|y

0

) is set via set_offset or

set_offset_list.

For 3-axis scan systems, set_offset_xyz or

set_offset_xyz_list enables setting of an offset z

0

for

the Z coordinate, too (z

0

has the opposite effect of

set_defocus or set_defocus_list). The following

applies:

The coefficients of the scaling matrix M

S

are set via

set_scale or set_scale_list using a scaling factor k

that is common to both axes:

The coefficients of the rotation matrix M

R

are set via

set_angle or set_angle_list by specifying a rotation

angle (mathematical definition: positive angles

produce counterclockwise rotation):

M

R

cos

o

–

o

sin–

sin

o

– cos

=

Loading...

Loading...