Installing cable fittings

Page 130 OmniTrax Product Guide

6. Push the center pin fully onto the center conductor. The center conductor must be visible

through the center pin’s inspection hole.

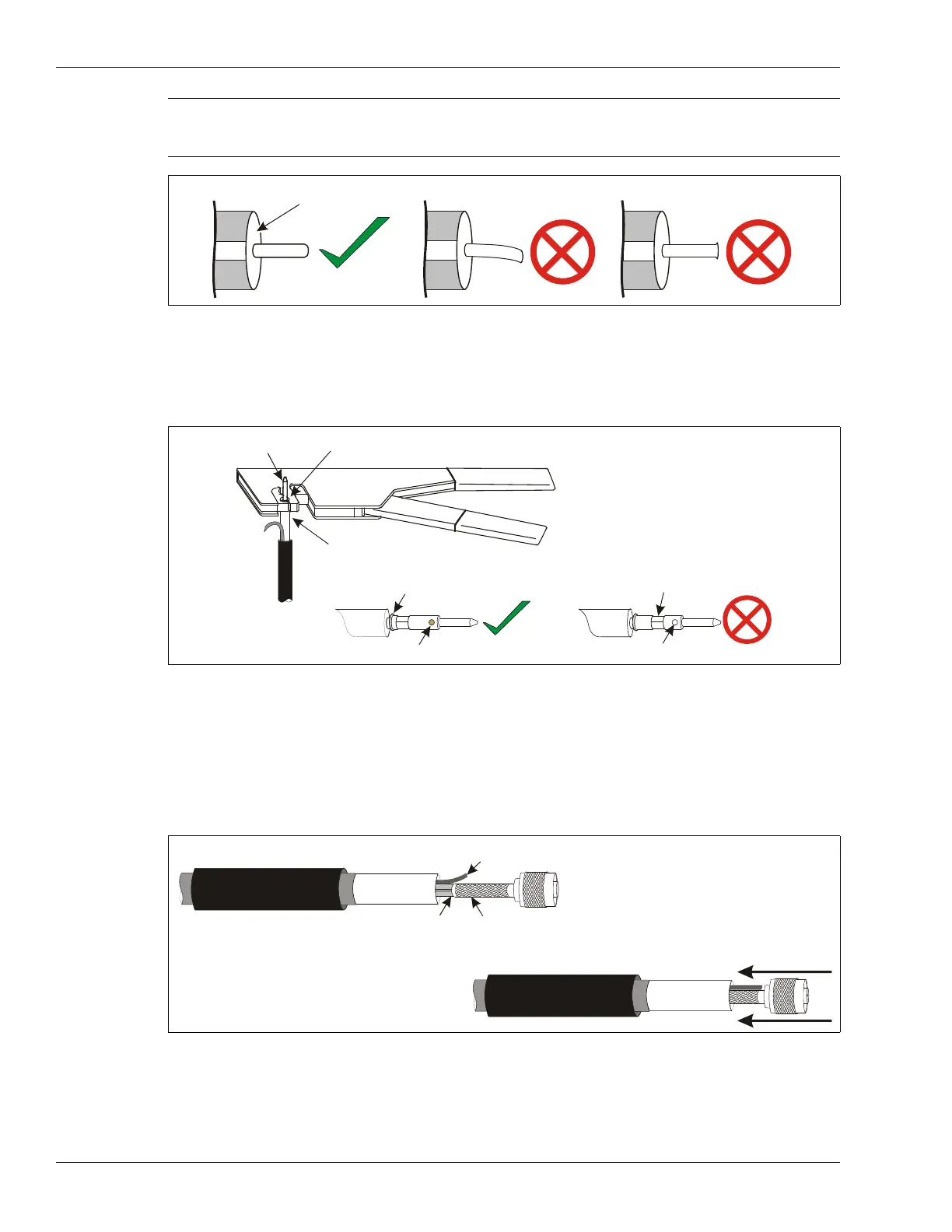

Using the smaller quad opening in the crimp tool, crimp the center pin once, as close to the

dielectric as possible. Do NOT crimp the shoulder of the center pin.

7. Slide the heatshrink over the end of the cable. Slide the crimp ring over the end of the cable

until it butts up against the gray jacket.

8. Lift the drain braid slightly and then fit the connector onto the sensor cable so the center pin,

dielectric core and foil covering fit smoothly inside the connector shell, and the drain braid

remains outside the connector shell.

Press the connector onto the cable until it clicks into place.

9. Slide the crimp ring over the connector shell and drain braid until it is flush against the head of

the connector.

Mark the location of the drain braid on the crimp ring.

Note Ensure that the center conductor is smooth (no lip or burr from cutting),

straight and 6 mm long.

There must be no foil on the flat cross section of the dielectric core.

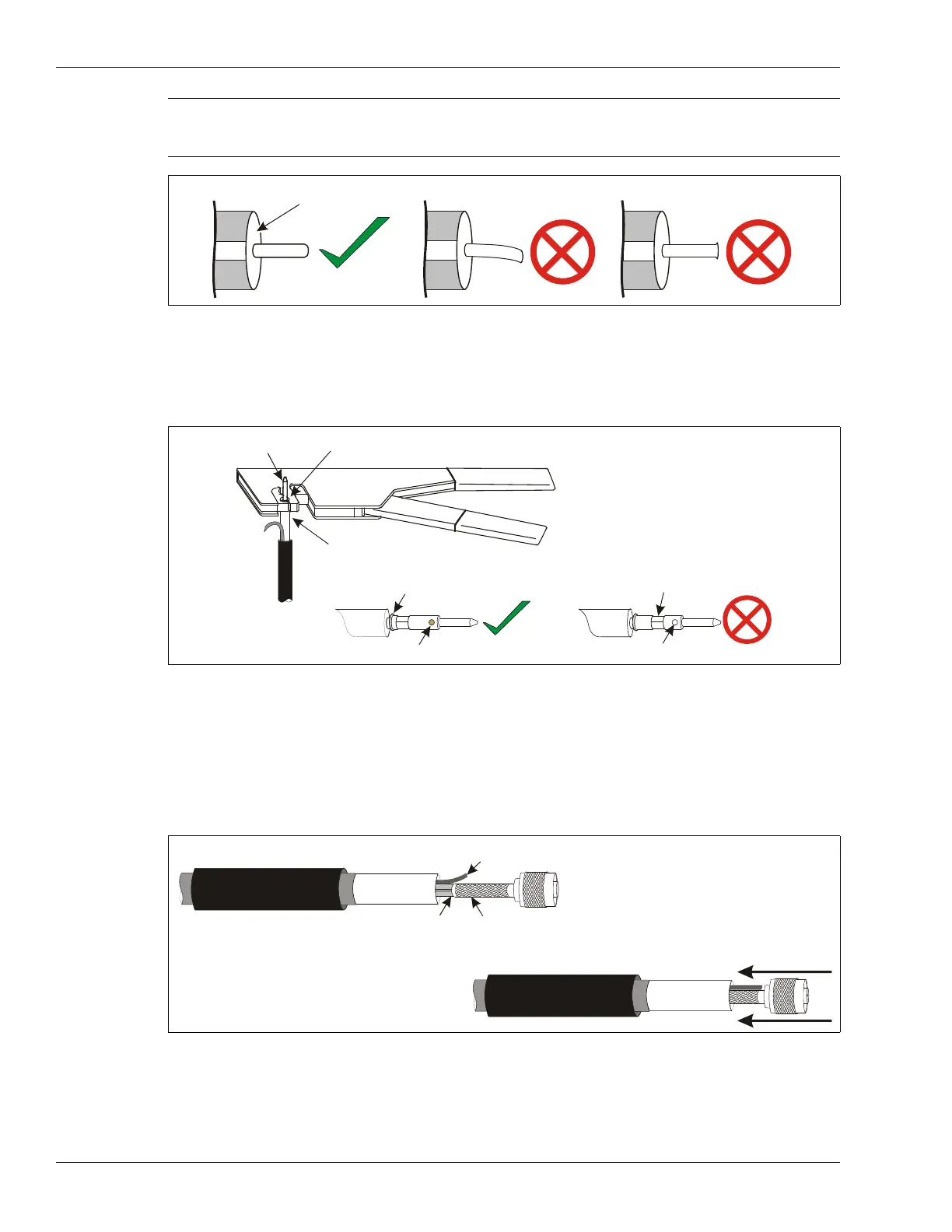

Figure 103: Trimming the center conductor

Figure 104: Crimping the center pin

Figure 105: Fitting the connector

center

conductor is bent

no foil on dielectric

core cross section

smooth straight center

conductor (6 mm long)

burr on

center conductor

use the small quad opening

center pin

dielectric core

center pin shoulder

center conductor visible

center conductor not visible

crimp not close enough to dielectric core

drain braid

crimp ring

heat shrink

connector shell

foil and

dielectric core

press the connector onto the cable

until it clicks into place

Loading...

Loading...