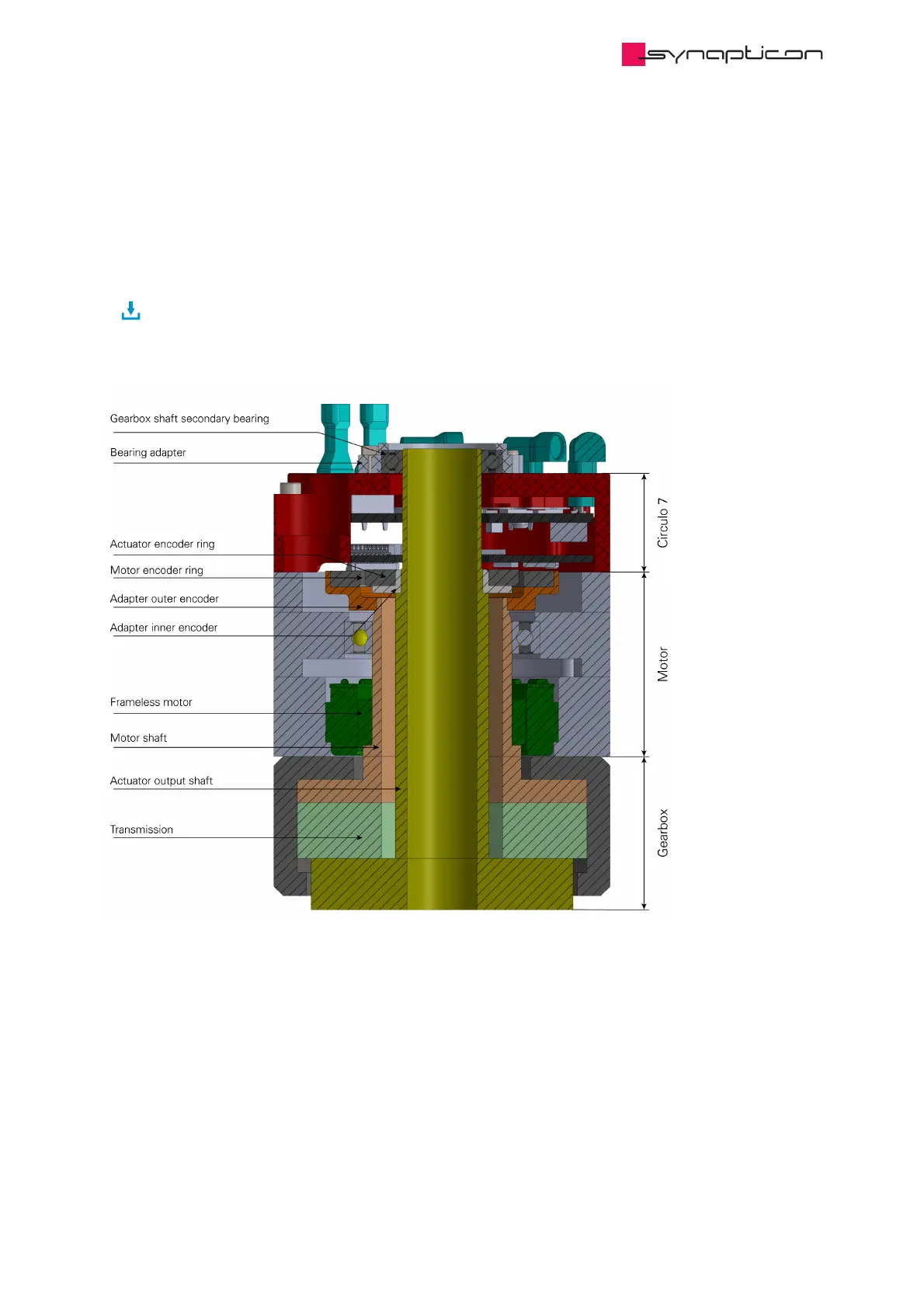

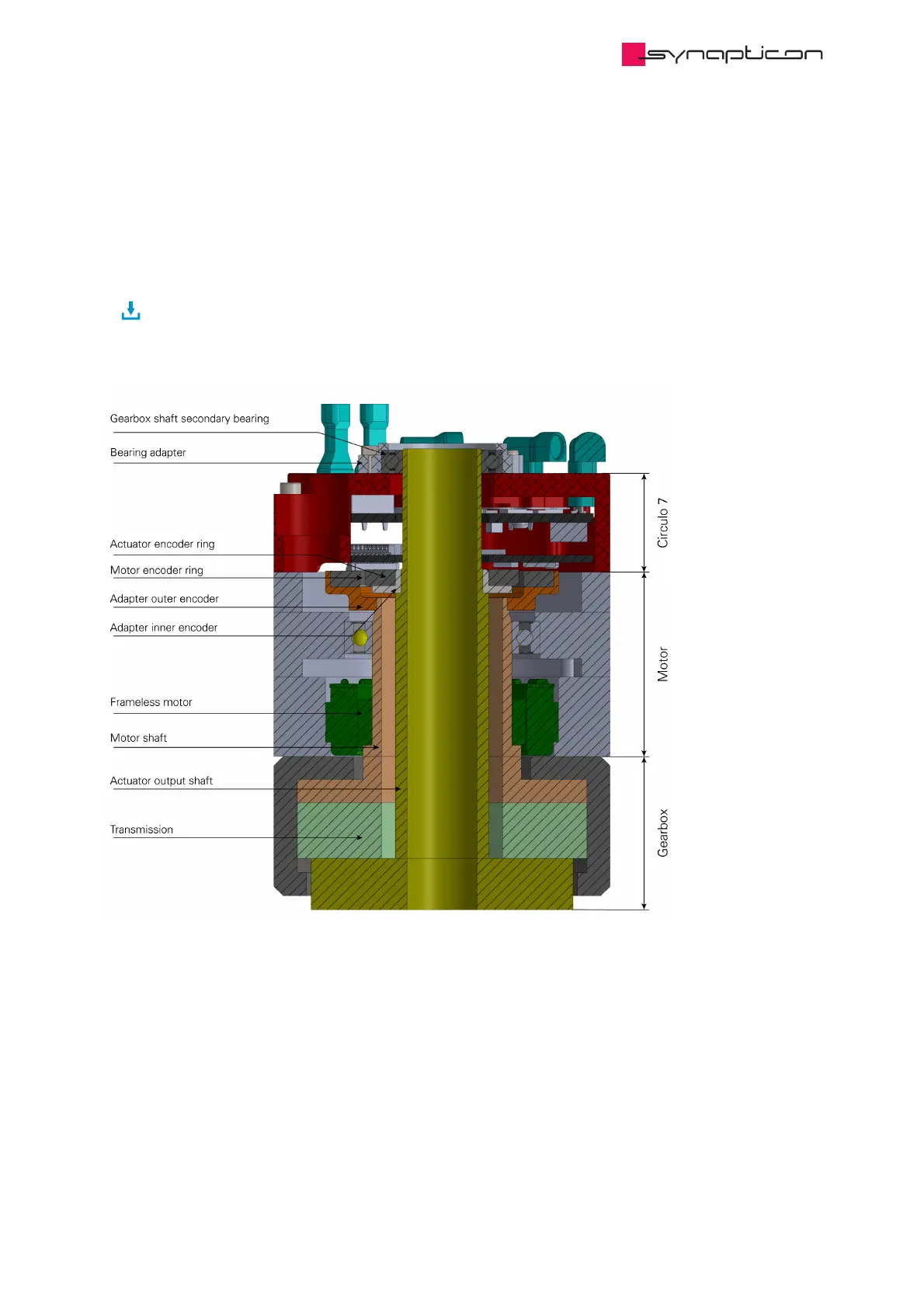

1.2.3.2.1 Circulo Mounting Example

Since the mounting situation is highly dependent on each individual design, an example of a hollow shaft

robotic actuator is presented that features the most important aspects.

The example project can be downloaded as a STEP file.

CIRCULO 7 MECHANICAL INTEGRATION EXAMPLE

It comprises the following components as shown in the graphic.

Circulo should be mounted to an even metal surface using 4 ISO 4762 M2.5 x 20 screws, tightened to 1 Nm

and using a screw lock (tested with Loctite 243). If the Circulo internal encoder is used, it is mandatory to use

two 3 mm ISO 8734 dowel pins for aligning the Circulo internal encoder read heads with the actuator. Circulo

is designed to induce excess heat into the actuator body, so it is recommended that the mounting surface

covers all the heatsink’s lower surface for optimal thermal performance.

The heat conducting surface should be sufficiently dimensioned and made of a suitable material, such as

aluminum.

Ensure that the servo drive is screwed properly to the heat conducting surface to facilitate the heat transfer.

Loading...

Loading...