ProcedureforCounterbalancePressureTest(continued)

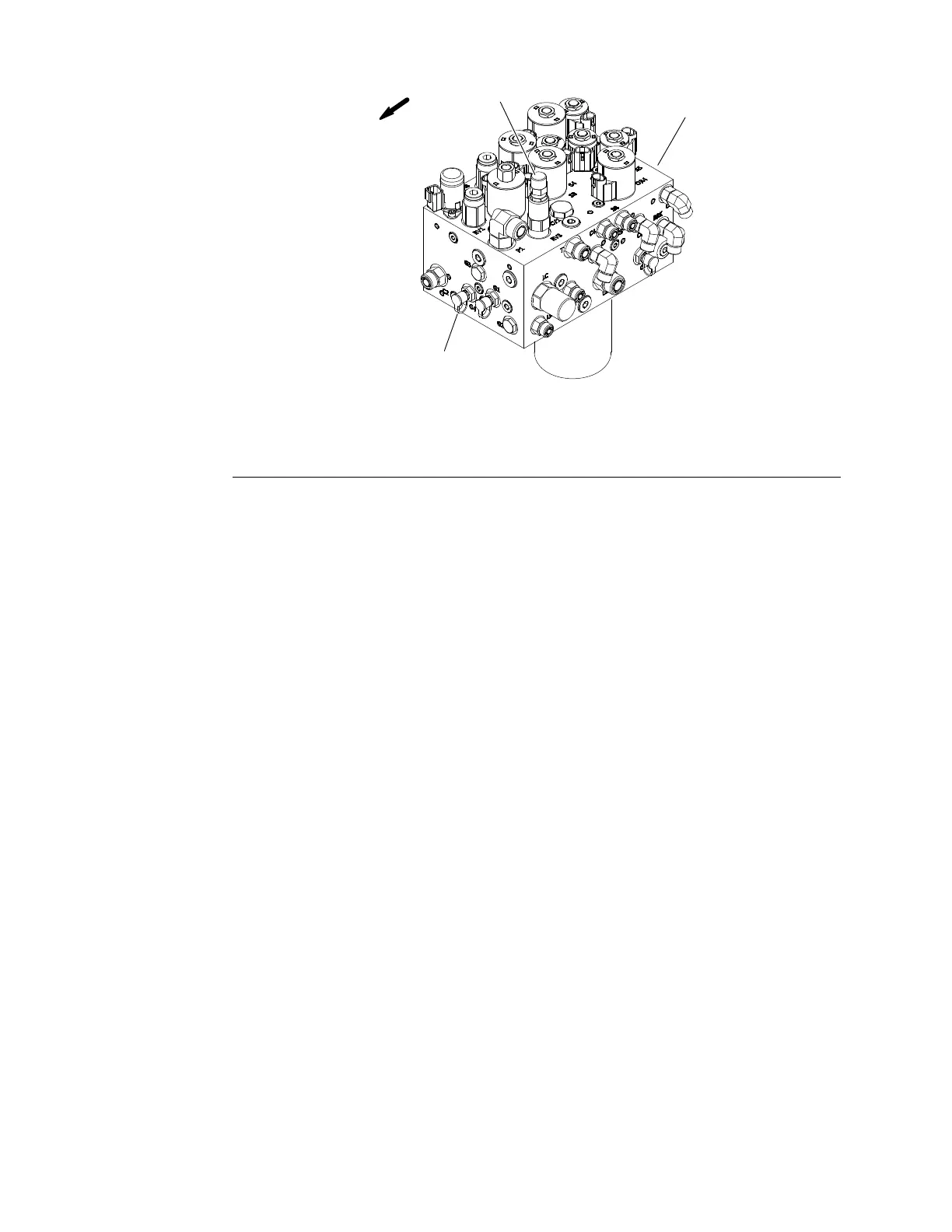

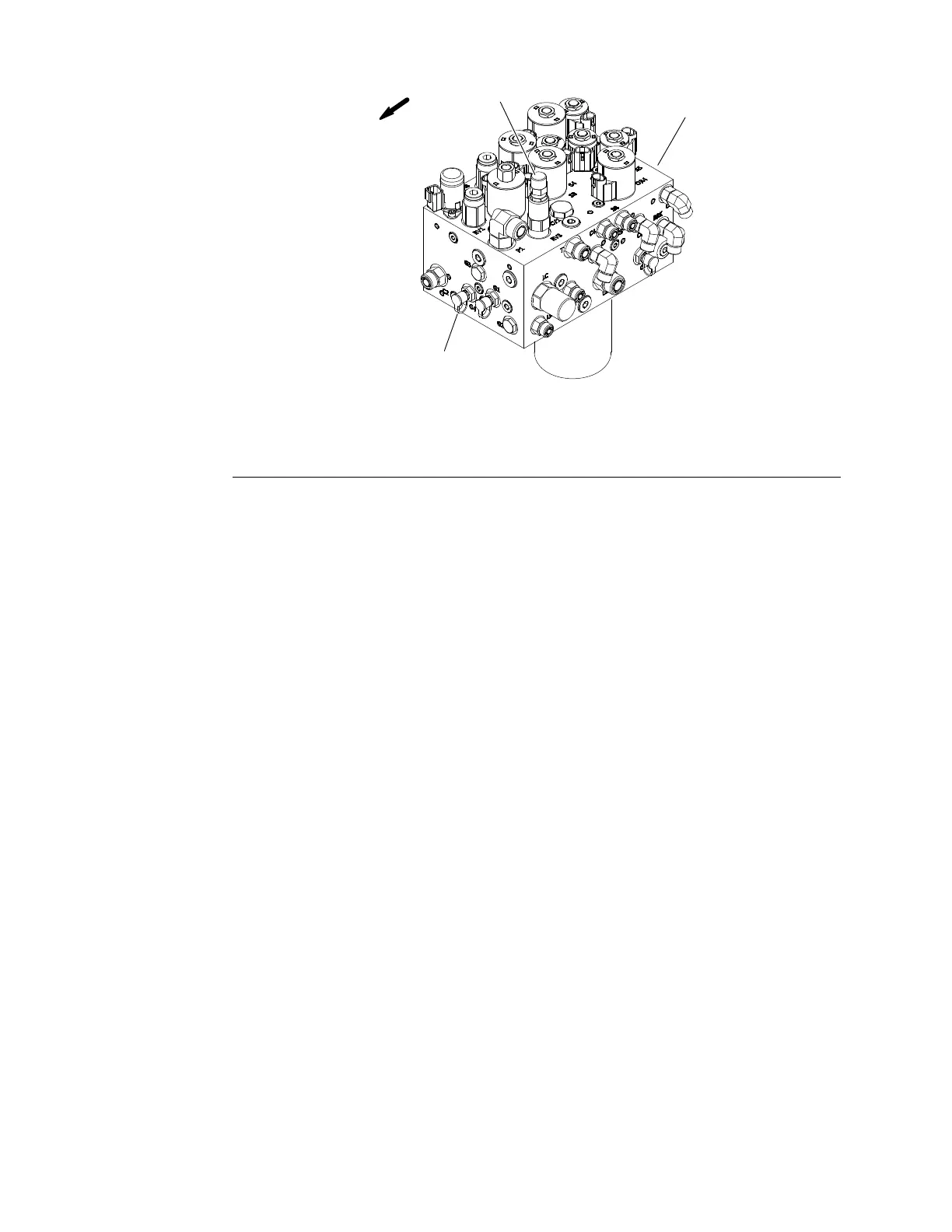

g287739

Figure54

1.Steering/liftmanifold3.Counterbalancevalve

2.T esttting(portG4)

4.Connecta70Bar(1000PSI)pressuregaugetotestttinginportG4on

steering/deckliftcontrolmanifold(Figure54).

5.Afterinstallingpressuregauge,startengineandrunatlowidlespeed.Check

forhydraulicleakageattesterconnectionsandcorrectbeforeproceeding

withtest.

6.Operatetheengineathighidlespeed(2530RPM)withnoloadonthe

system.Donotengagethecuttingdecks.

GAUGEREADINGTOBE:21to29bar(305to425PSI).

7.Stopengineandrecordtestresults.

Note:Ifhydraulicoilisnotatnormaloperatingtemperatureoriftraction

chargereliefpressureishigh,counterbalancepressurewillbehigherthan

normal.

8.Ifnecessary,adjustthecounterbalancevalve(RV3)sothatcounterbalance

pressureiscorrect(seeAdjustManifoldReliefValves(page5–72)).The

counterbalancevalve(RV3)islocatedonthetopofthesteering/decklift

manifold(Figure54).

9.Whencounterbalancetestingiscomplete,disconnectpressuregaugefrom

testtting.Lowerandsecurehood.

HydraulicSystem:Testing

Page5–46

Groundsmaster

®

5900&5910

16227SLRevB

Loading...

Loading...