ProcedureforGearPumpFlowTest(continued)

IMPORTANT

Topreventhydraulictesterdamage,use40GPMHydraulicTester

#AT40002(pressureandow)andHoseKitforthistest(seeSpecial

Tools(page2–15)).

IMPORTANT

Makesurethattheoilowindicatorarrowontheowgaugeis

showingthattheoilwillowfromthehydraulichosefromthepump,

throughthetesterandintothemanifoldtting.

3.Install40GPMtester(owandpressure)inserieswiththedisconnected

hoseandhydraulicttinginmanifold.

4.Makesuretheowcontrolvalveontesterisfullyopen.

5.Startengineandincreaseenginespeedtohighidlespeed(2530RPM).Do

notengagethecuttingdecks.Checkforhydraulicleakageattestconnection

andcorrectbeforeproceedingwithtest.

6.Makesurehydraulicoilisatnormaloperatingtemperature(54to66ºC(130

to150ºF))byoperatingthemachineforapproximatelyten(10)minutes.

Makesurethehydraulicreservoirisfull.

IMPORTANT

Donotfullyrestrictoilowthroughtester.Inthistest,theowtester

ispositionedbeforethecircuitreliefvalve.Pumpdamagecanoccur

iftheoilowisfullyrestricted.

7.Watchpressuregaugecarefullywhileslowlyclosingtheowcontrolvalve

until69bar(1000PSI)isobtained.VerifywiththeInfoCenterdisplaythatthe

engineisstillrunningatthecorrecthighidlespeed(2530RPM).

Note:Ifenginespeeddropsduringtesting,pumpowwilldecreaseand

owtestresultswillbeinaccurate.

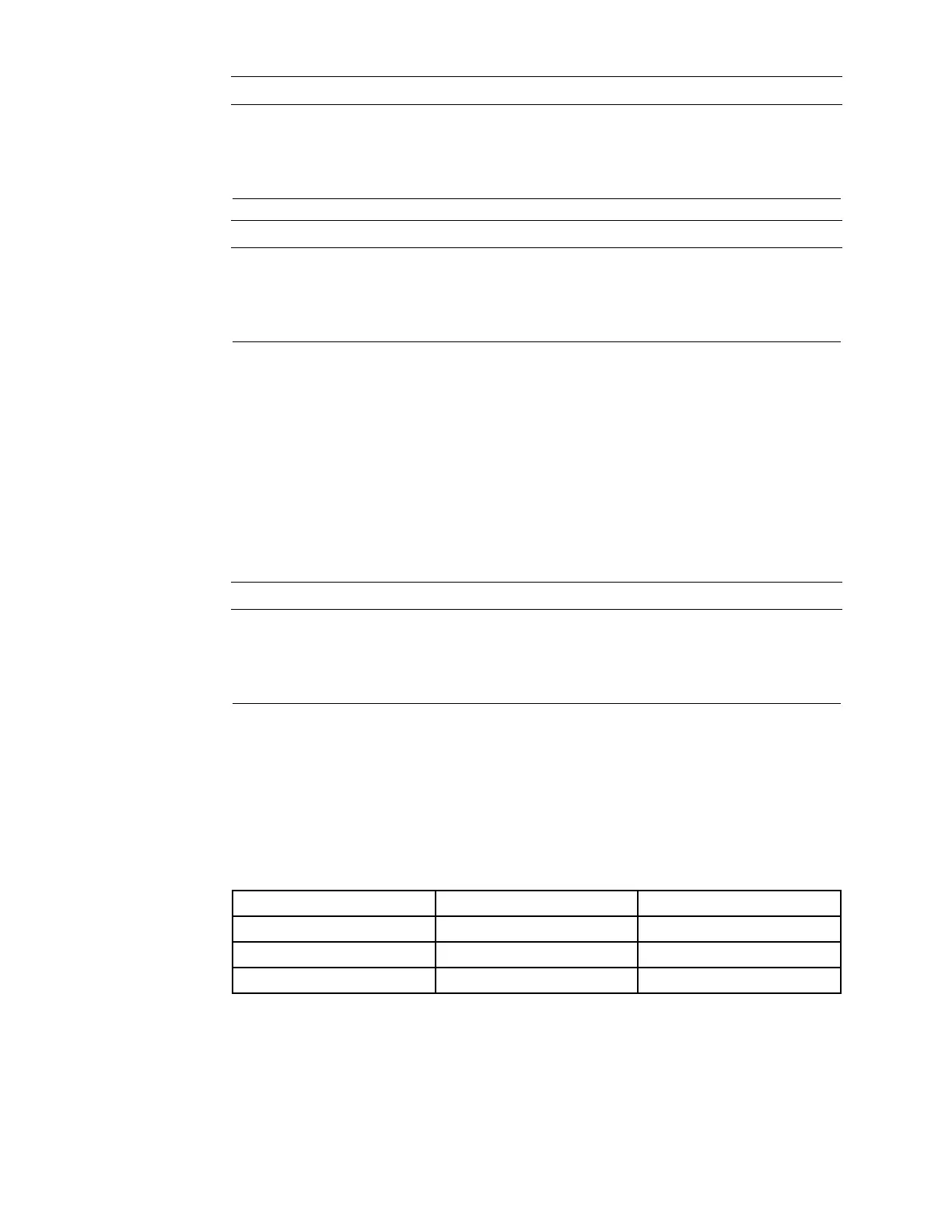

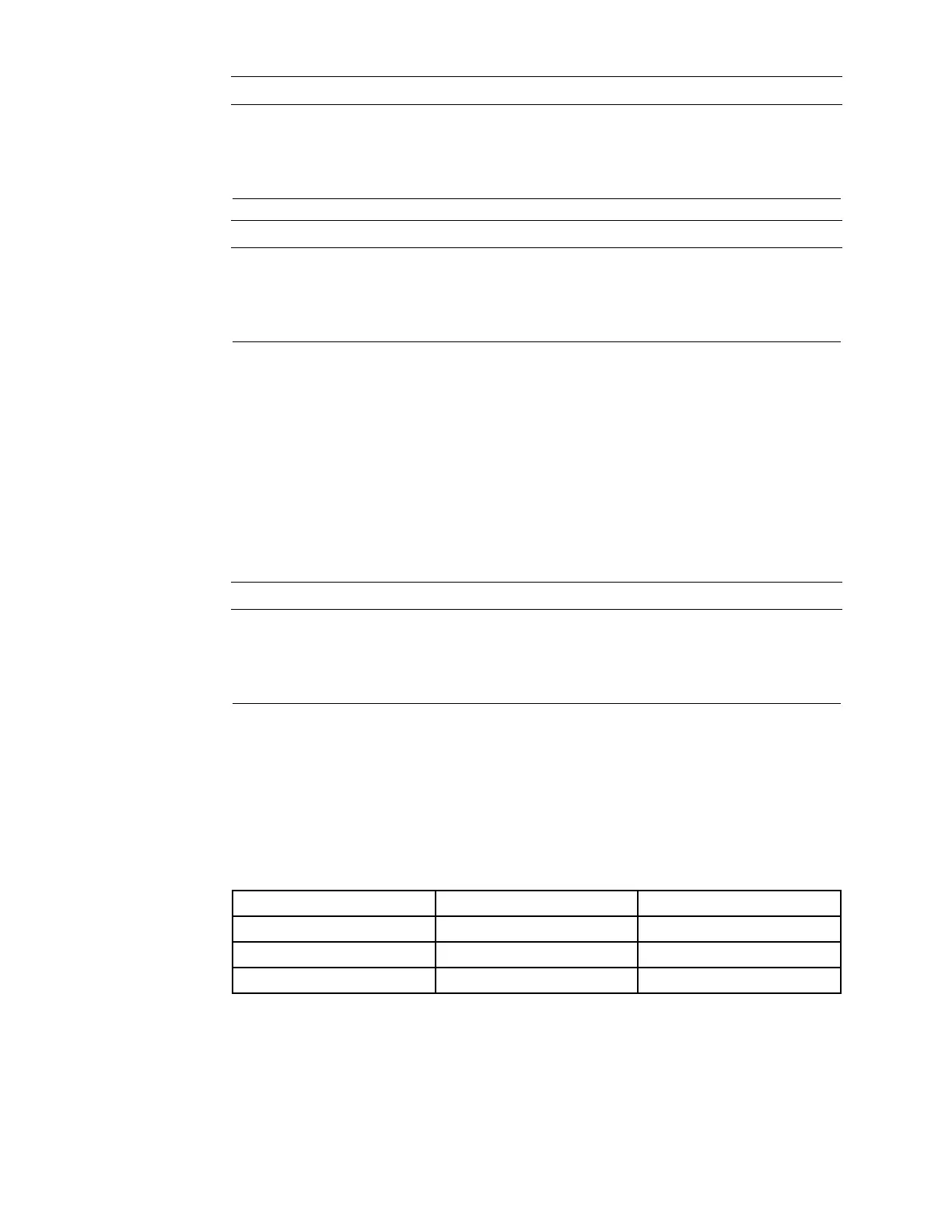

8.Normalowindicationforthethree(3)gearpumpsectionsislistedinbelow

table:

PUMPSECTIONNORMALFLOWMINIMUMFLOW

FIRSTSECTION83LPM(22GPM)74LPM(19.6GPM)

SECONDSECTION83LPM(22GPM)74LPM(19.6GPM)

THIRDSECTION40LPM(10.6GPM)36LPM(9.5GPM)

9.Oncethegearpumpsectionowhasbeendetermined,opentesterow

controlvalveandstopengine.Recordtestresults.

HydraulicSystem:Testing

Page5–70

Groundsmaster

®

5900&5910

16227SLRevB

Loading...

Loading...