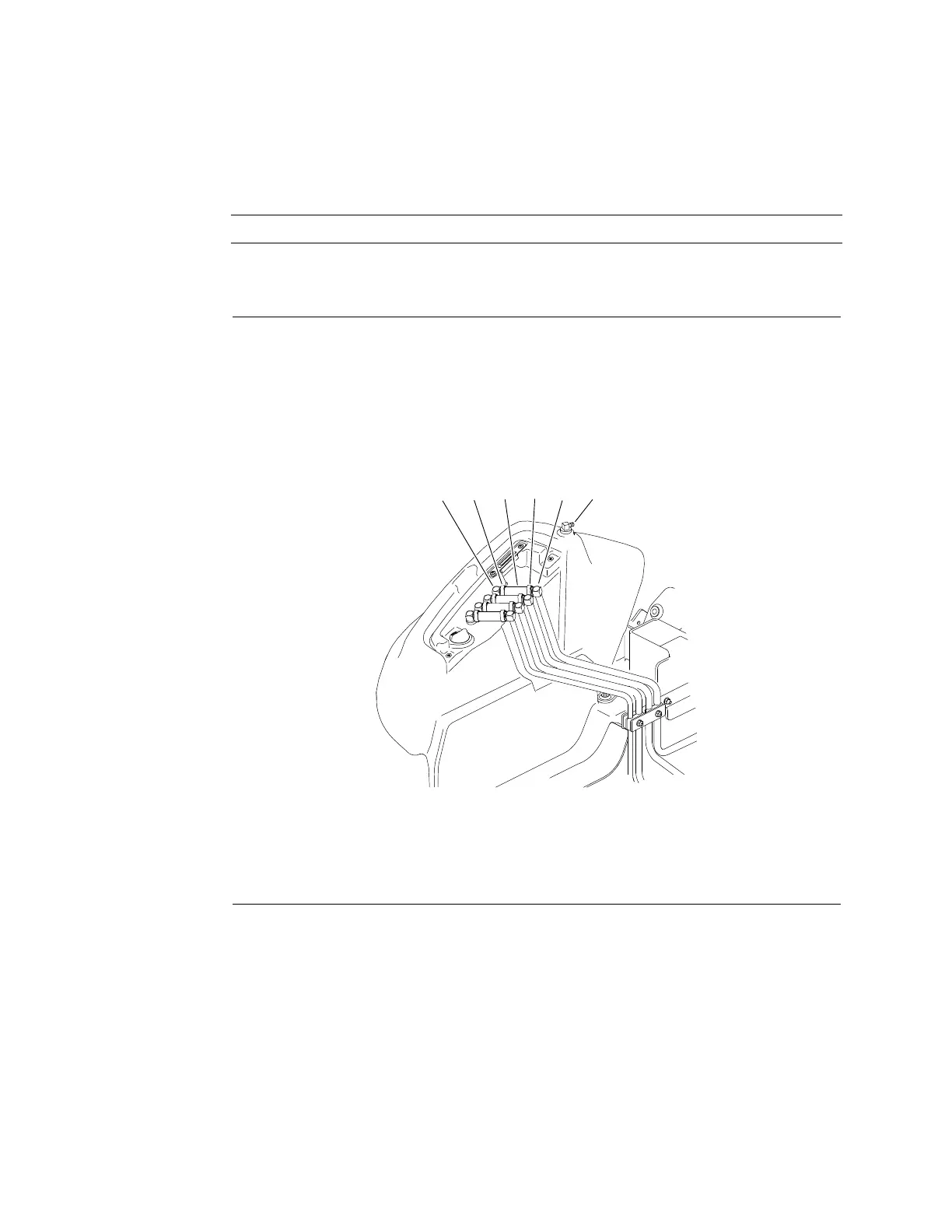

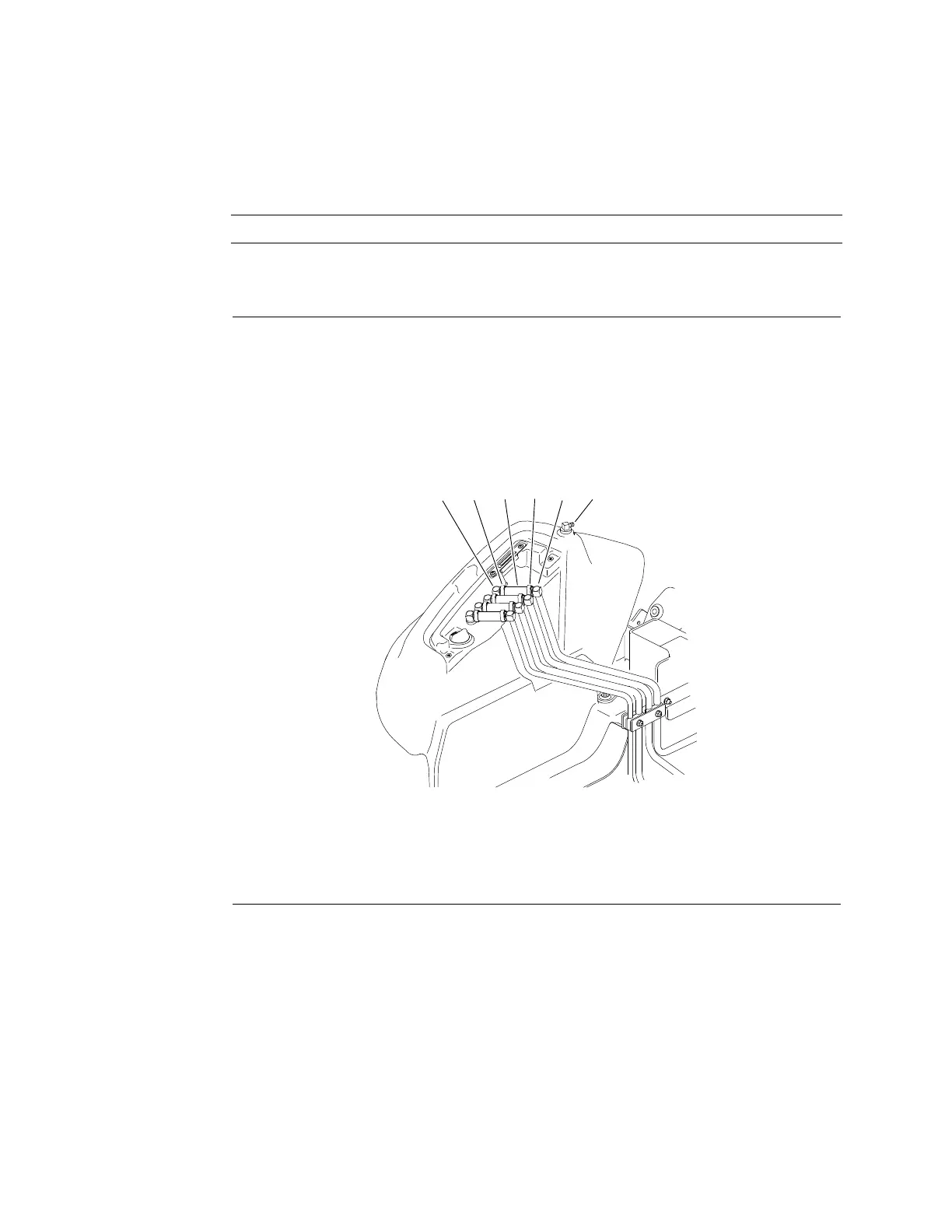

HydraulicReservoirRemoval(Figure79)

1.Parkmachineonalevelsurface,lowercuttingdecksfully,disengagePTO

andstopengine.Removekeyfromkeyswitch.

2.ReadtheGeneralPrecautionsforRemovingandInstallingHydraulicSystem

Components(page5–73).

3.Topreventcontaminationofhydraulicsystemduringhydraulicreservoir

removal,thoroughlycleanexteriorofreservoir,ttingsandhoses.

IMPORTANT

Followalllocalcodesandregulationswhenrecyclingordisposing

hydraulicuid.

4.Removedrainplugfromthehydraulicreservoiranddrainreservoirinto

asuitablecontainer.

5.Toallowaccesstoreservoirholddownandfasteners,loosenfueltankand

slideittowardleftsideofmachine(seeFuelSystem(page4–17)).

6.Removereservoirholddown(item24)andcapscrew,atwasherandspacer

atfrontofreservoir(item18).

g287877

Figure80

1.Standpipe

4.Hydraulictube

2.Hoseclamp

5.Venttting

3.Hose

7.Toeaseassembly,labelallhydraulichosestoidentifytheircorrectposition

onthereservoir.

Note:Originalproductionclampsusedtosecurefour(4)hosestostand

pipesandhydraulictubesarecrimptypeclampsandwillneedtobecutin

ordertoremovehoses(Figure80).Traditionalwormtypeclampscanbe

usedasreplacements.

8.Disconnecthydraulichosesfromstandpipes,ventttingandsuctionstrainer.

Putcapsorplugsonttingsandhosestopreventcontamination.

9.Removehydraulicreservoir.

HydraulicSystem:ServiceandRepairs

Page5–84

Groundsmaster

®

5900&5910

16227SLRevB

Loading...

Loading...