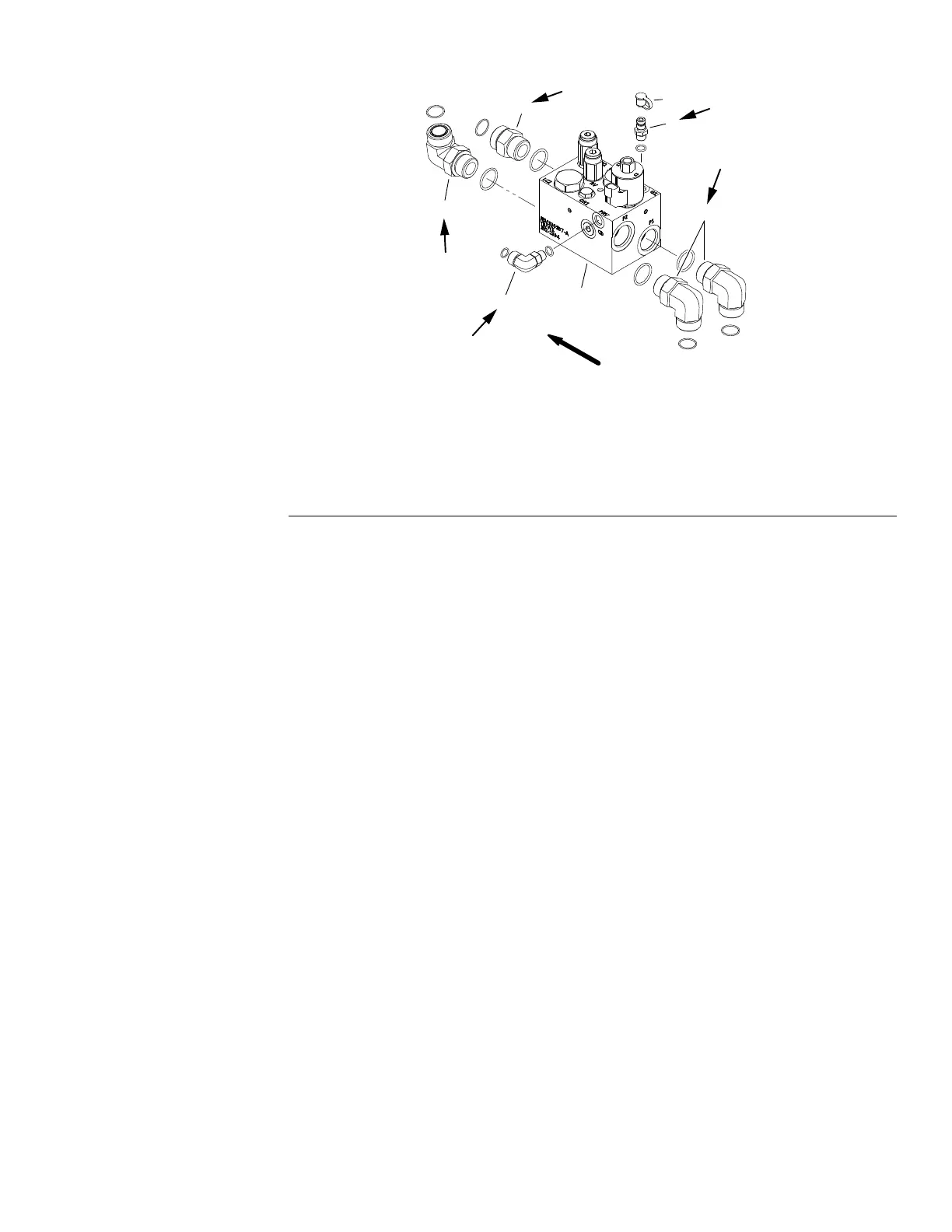

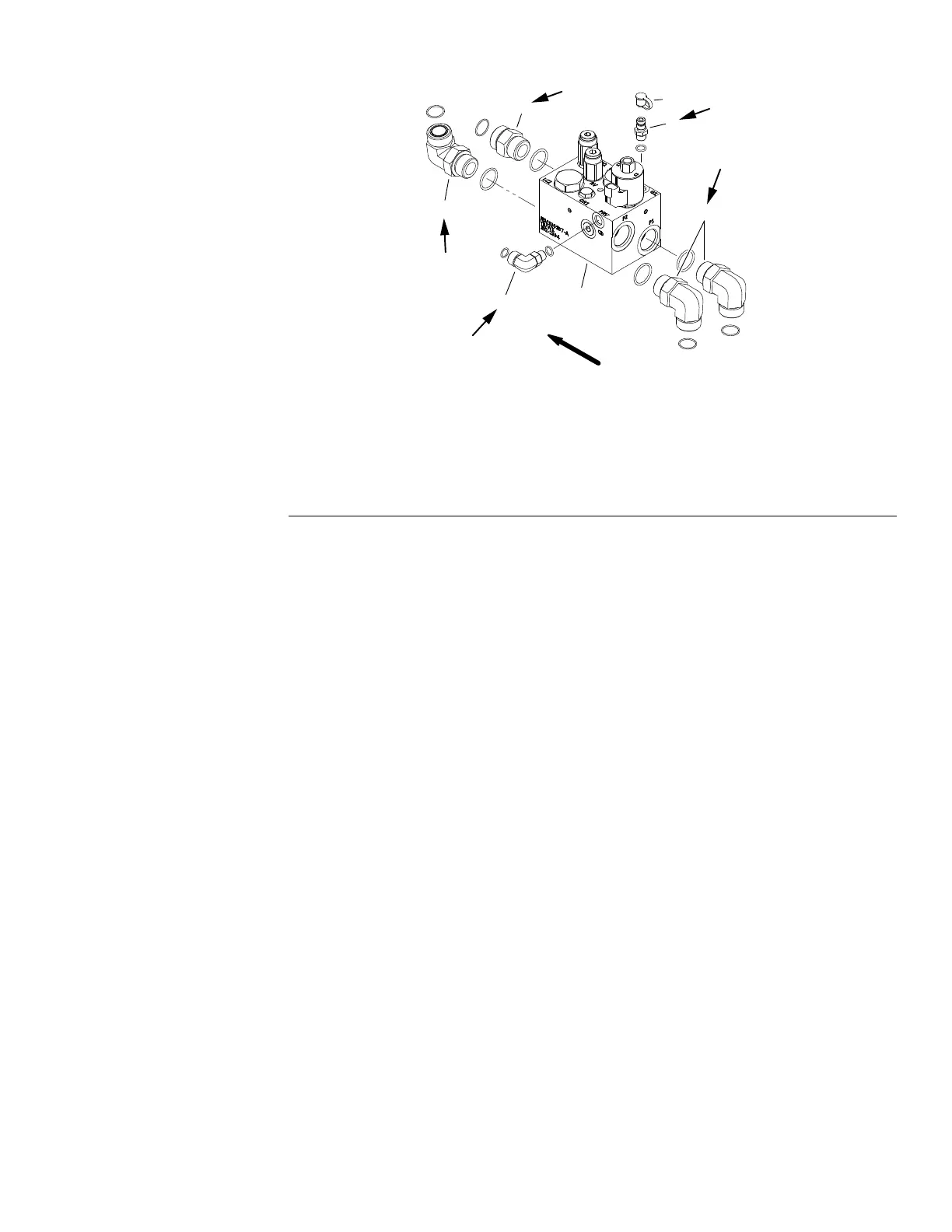

CuttingDeckControlManifoldInstallation(Figure110)(continued)

FRONT

1

2

3

4

34 N·m

(25 ft−lb)

34 N·m

(25 ft−lb)

102 N·m

(75 ft−lb)

102 N·m

(75 ft−lb)

102 N·m

(75 ft−lb)

4

6

5

g288134

Figure113

LHDeckControlManifold

1.LHcontrolmanifold4.Hydraulic90ºtting(3)

2.Dustcap

5.Straighttting

3.Diagnostictting6.Hydraulic90ºtting

1.Ifttingswereremovedfrommanifold:

A.LubricatenewO−ringswithcleanhydraulicoil.InstalllubricatedO−rings

onttings.

B.Installttingsintomanifoldopeningsusingmarksmadeduringthe

removalprocesstoproperlyorientatettings.

C.Tightenhydraulicttingstotorquevalueprovided(Figure111,Figure112

andFigure113).Forinformationontighteningproceduresforhydraulic

ttings,seeInstallingtheHydraulicFittings(SAEStraightThreadO-Ring

Fittings)(page5–9).

2.PositionPTOcontrolmanifoldtotheframeandsecurewithtwo(2)cap

screws,atwashersandangenuts.

3.Removecapsandplugsfromttingsandhoses.Properlyconnecthydraulic

linestomanifold(seeInstallingHydraulicHosesandTubes(O-RingFace

Seal)(page5–7)).

4.Connectwireharnessconnectortotheproportionalreliefvalvesolenoid.

5.Makesurehydraulictankisfull.Addcorrectoilifnecessary.

6.Checkhydraulicsystemforleaksbeforereturningthemachinetoservice.

Groundsmaster

®

5900&5910

Page5–127

HydraulicSystem:ServiceandRepairs

16227SLRevB

Loading...

Loading...