ImpactArmAssembly(Figure310)(continued)

IMPORTANT

Allendplaymustberemovedfromspringshaftassemblytoallow

properoperationandensurelonglife.

4.Graspendofspringshaft.Pushinwardandpulloutwardonshaftto

determineifendplayexistsbetweenspringshaftassemblyandimpactarm

housingassembly.

5.Ifendplayinspringshaftassemblyexists,inserta3/4”socketontojamnut

(item21)onspringshaft.Accesstojamnutcanbeobtainedthroughthe

openendofimpactarmhousing.Loosenjamnutuntilallendplayinshaft

isremoved.

6.Whennoendplayexistsinspringshaftassembly,removetwo(2)capscrews

andnutssecuringhousingtoimpactarmhousingandremovespringshaft

assemblyfromhousing.

7.Threadsecondjamnut(item21)ontoendofspringshaft.Whileholdingrst

jamnutwithawrenchtopreventitfromturning,tightensecondjamnutfrom

184to223N·m(135to165ft−lb)tosecurespringadjustment.

8.Thoroughlypackspringwithgrease.Applyapproximately1.1kg(40oz)

ofgreasetoacleanspring.

9.Installspringshaftassemblyintoimpactarmhousingandsecurehousing

(item13)withfour(4)capscrewsandlocknuts.

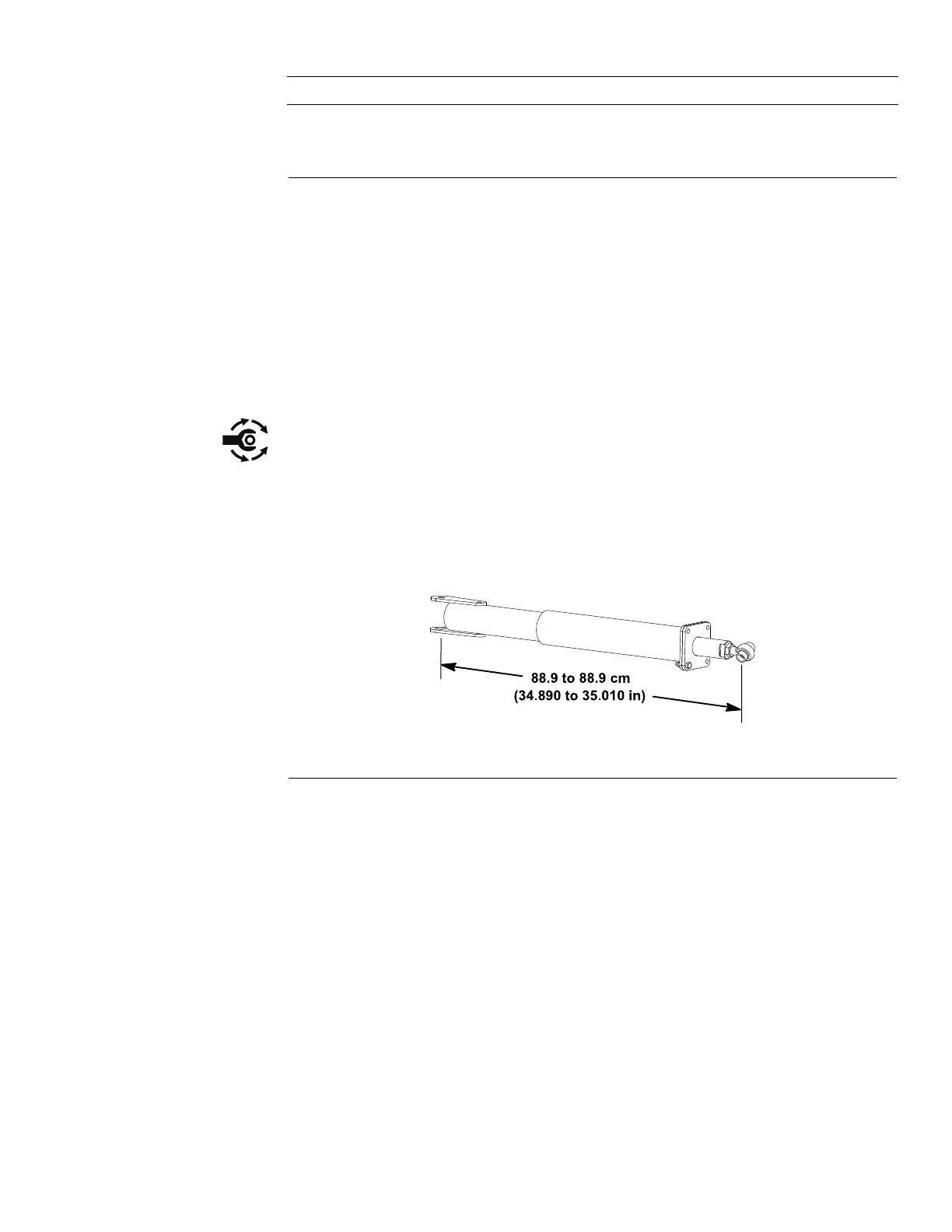

g299091

Figure312

10.Threadrodend(item22)withjamnutintoendofspringshaftsothatdistance

fromcenterofrodendtocenterofimpacthousingmountingholeisfrom

88.6to88.9cm(34.89to35.01in)(Figure312).Donottightenjamnut

untilimpactarmisinstalledtodeck.

ImpactArmInstallation(Figure310andFigure311)

1.Positionimpactarmassemblytocuttingdeckconnectionandframe.

2.Slidepivotshaft(item4)throughimpactarmhousingandhub.Securepivot

shaftwithatwasherandlocknut.

3.Positionaspaceroneachsideofimpactarmrodend.Securerodendto

deckconnectionwithcapscrew(item26)andlocknut.

4.Tightenrodendjamnut(item24).

5.Lubricateimpactarmpivothubgreasetting.

6.Afterinstallationiscompleted,raiseandlowerthecuttingdecktoverifythat

hydraulichosesandttingsdonotcontactanythingthroughouttheentire

rangeofmovement.

Groundsmaster

®

5900&5910

Page7–33

Chassis:ServiceandRepairs

16227SLRevB

Loading...

Loading...