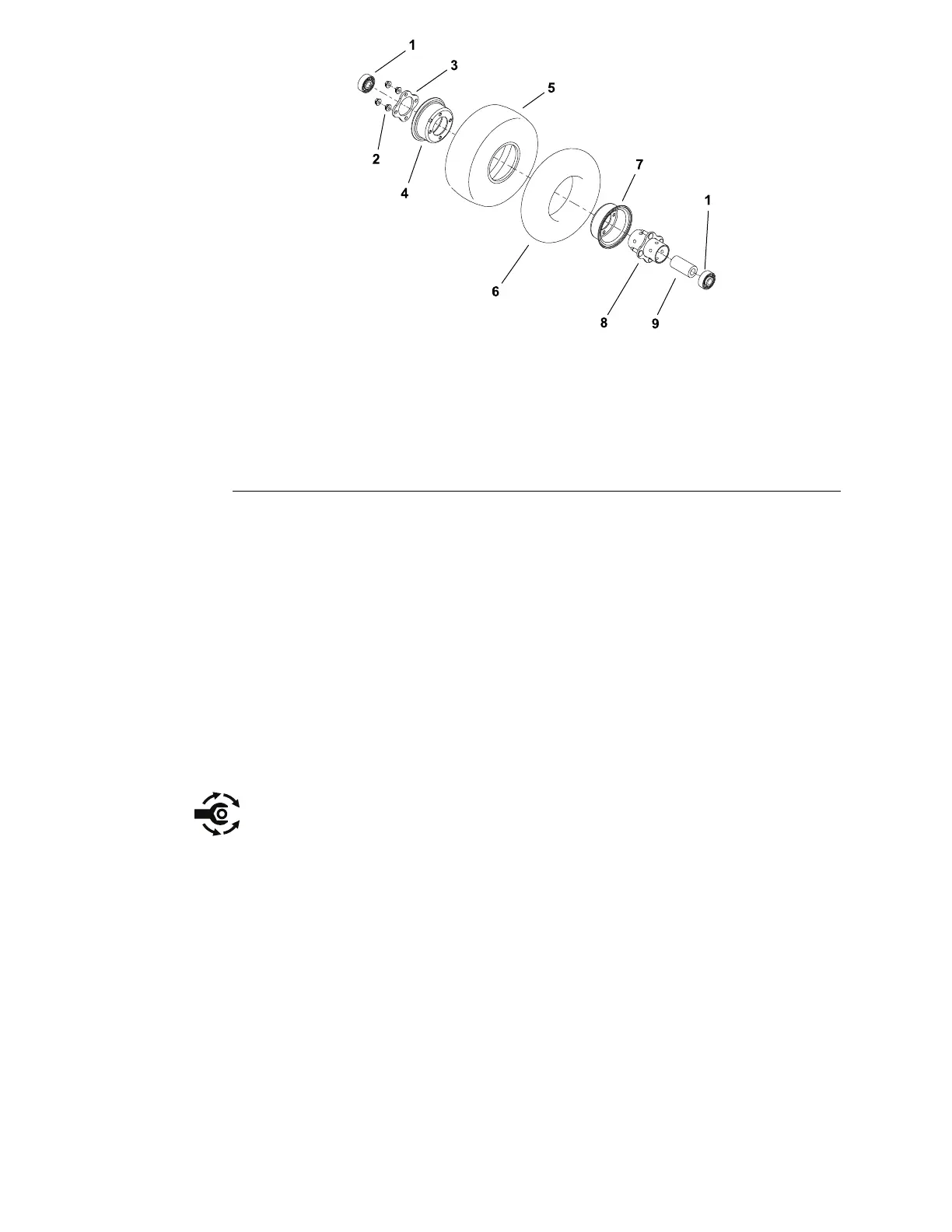

g299725

Figure338

1.Bearing(2)

6.Innertube

2.Flangenut(4)7.Rimhalf

3.Plate8.Hub

4.Rimhalf

9.Bearingspacer

5.Tire

CastorWheelDisassembly(Figure337andFigure338)

Disassemblecastorforksandwheelsasneeded.

CastorWheelAssembly

1.Ifthecasterarmwasremovedformcuttingdeck,insertcastorarmboltswith

boltheadtowardtheoutsideofthecuttingdeck.

2.Assemblecastorforksandwheelsasneeded.

A.Makesuretoinstallallthecastorwheelsonallthecuttingdecksinthe

samemountingholeheightposition(lower,orupper).

B.Installcastorwheelssothatvalvestemextendstowardtheoutsideof

themachine.

C.Insertcastorwheelboltswithboltheadtowardtheoutsideofthemachine.

Tightencastorwheellocknutfrom81to108N·m(60to80ft−lb).

3.Castortirepressureshouldbe345kPa(50PSI).

4.Lubricatecastorforkgreasetting.

5.Checkheight−of−cutsettingandadjustifnecessary.

CuttingDecks:ServiceandRepairs

Page8–22

Groundsmaster

®

5900&5910

16227SLRevB

Loading...

Loading...