AirFilterInstallation

IMPORTANT

Anyleaksintheairltersystemwillcauseseriousenginedamage.

Makesurethatallairltercomponentsareingoodconditionandare

properlysecuredduringinstallation.

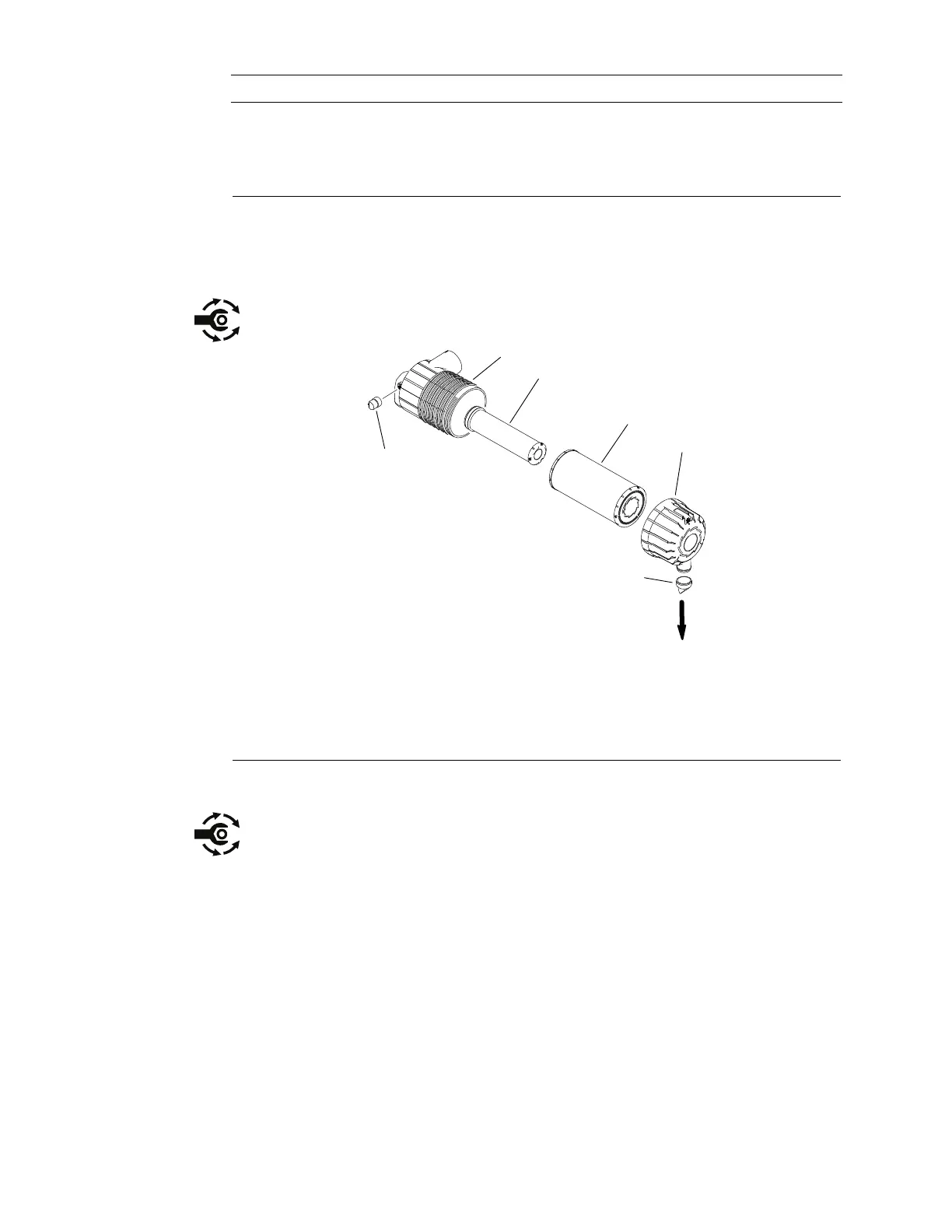

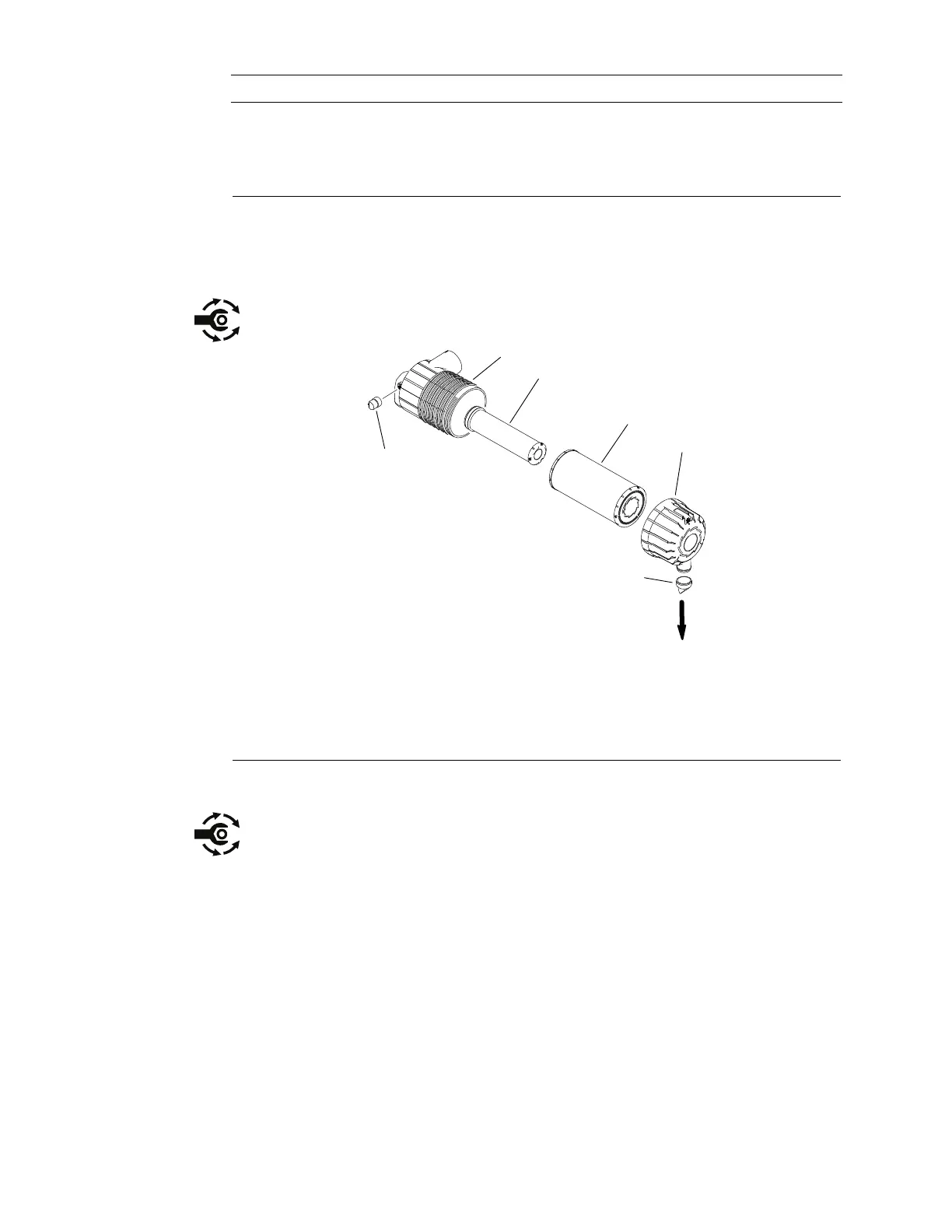

1.Assembleairltersystem(Figure15):

A.Verifythattabsinairltermountingbandsmeshfullywithslotsinair

lterbody.

B.Tightenintaketubehoseclampsfrom10to112N·m(90to100in−lb).

1

2

3

4

5

6

VACUATOR

DIRECTION

VALVE

g287548

Figure16

1.Airlterhousing4.Safetylter

2.Cover5.Serviceindicator

3.Filterelement6.Vacuatorvalve

C.Makesurethatairltervacuatorvalveispointeddownafterassembly

(Figure16).

D.Ifserviceindicator(Figure16item5)wasremovedfromairlterhousing,

applythreadsealanttoadapterthreadsbeforeinstallingindicatorto

housing.Tightenindicatorfrom1.5to1.9N·m(13to17in−lb).

2.Lowerhoodandcheckthathoodmakesacontinuoussealaroundairbox

foamseals.Replacefoamsealsifnecessary.

3.Lowerandsecurehood.

YanmarDieselEngine:ServiceandRepairs

Page4–12

Groundsmaster

®

5900&5910

16227SLRevB

Loading...

Loading...