6.1 Common Settings

6-3

J

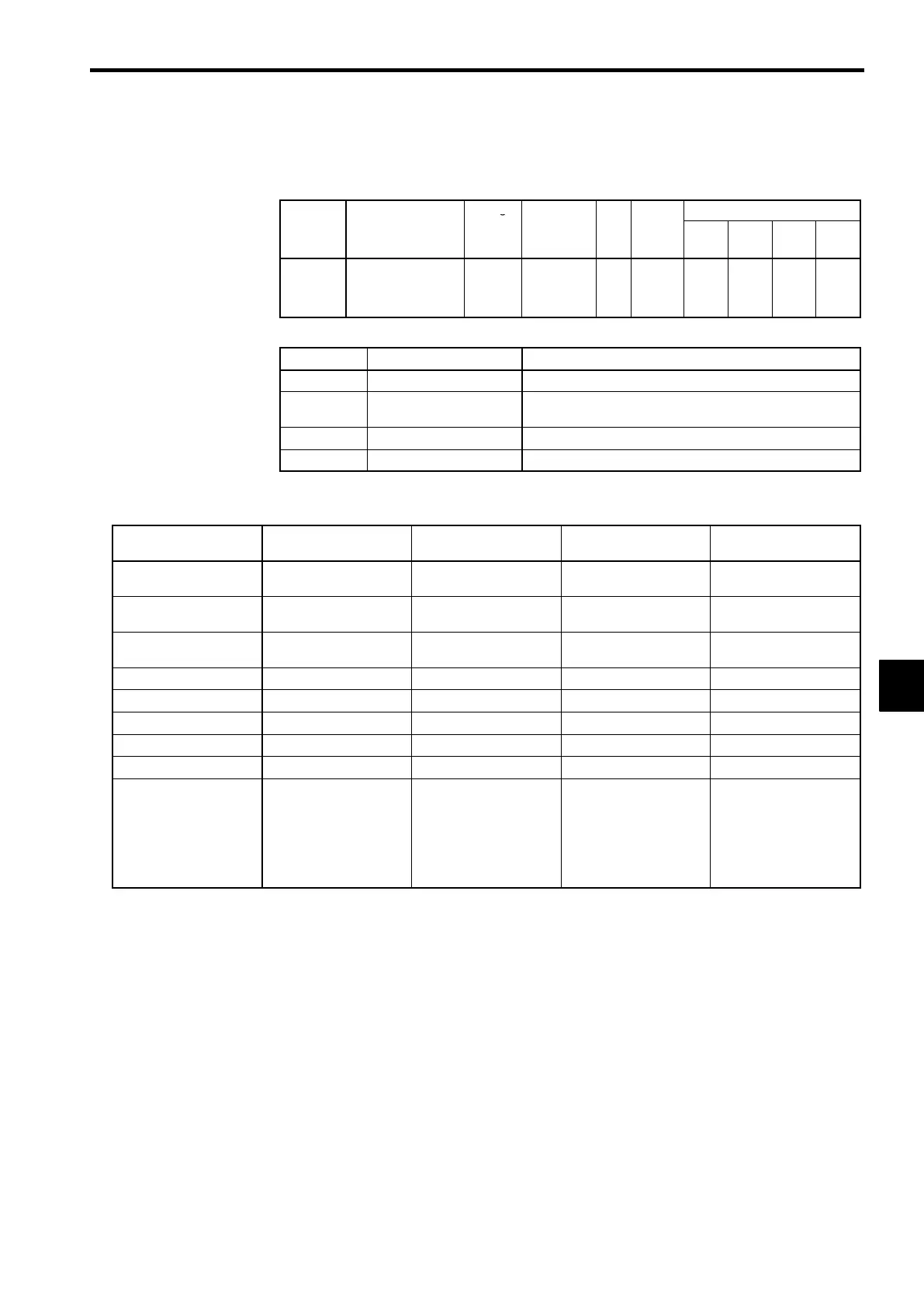

Control Method: A1-02

D

Select one of the four control methods.

D

This constant is not initialized by the initialize operation.

User

Change

Valid Access Levels

Constant

Number

Name

during

Opera-

tion

Setting

Range

Unit

Factory

Setting

V/f

Control

V/f with

PG

Open

Loop

Vector

Flux

Vector

A1-02

Control method

selection

×

0to3 −

2

Open

Loop

Vector

Q Q Q Q

D

Control Method Settings

Setting Control Method Function

0 V/f control

Normal V/f control

1 V/f control with PG feed-

back

V/f control using a PG Speed Control Card

2 Open loop vector control

Vector control using the Inverter’s internal speed information

3 Flux vector control

Vector control using a PG Speed Control Card

D

The characteristics of each control method are shown in Table 6.1.

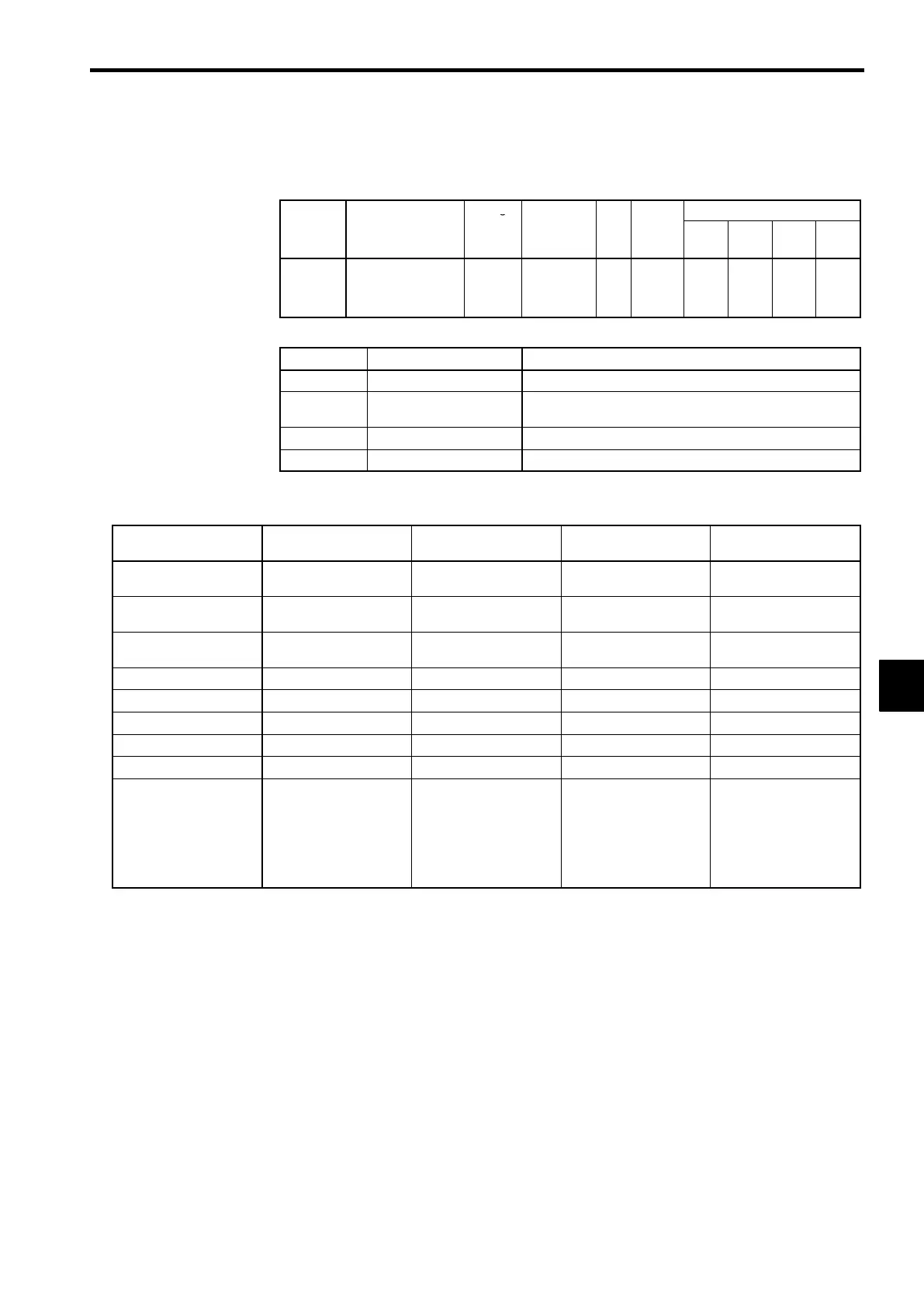

Table 6.1 Control Method Characteristics

Characteristic V/f Control

V/f Control w/PG Feed-

back

Open Loop Vector Flux Vector

Basic control method

Voltage/frequency control

(open loop)

Voltage/frequency control

with speed compensation

Current vector control

without PG

Current vector control with

PG

Speed detector

Not required

Required

(pulse generator)

Not required

Required

(pulse generator)

Optional speed detec-

tors

Not required PG-A2 or PG-D2 Not required PG-B2 or PG-X2

Speed control range

1:40 1:40 1:100 1:1000

Starting torque

150%/3 Hz 150%/3 Hz 150%/1 Hz 150%/0 r/min

Speed control accuracy

± 2to3% ± 0.03% ± 0.2% ± 0.02%

Torque limit

Not possible Not possible Possible Possible

Torque control

Not possible Not possible Not possible Possible

Example applications

S Multiple motor drives.

S Replacing existing mo-

tor for which motor

constants are not

known.

S When autotuning is not

possible.

S Simple speed feedback

control.

S When a pulse generator

is attached to the ma-

chine axis.

S Variable speed drive ap-

plications.

S Simple servo drives.

S Precision speed control.

S Torque control.

D

Vector control has a greater starting torque and more precise speed control than V/f control, so use of

vector control is recommended whenever possible.

Use V/f control in the following types of applications:

•

When several motors are being operated

•

When special motors, such as submersible motors or spindle motors, are being used

(situations in which auto-tuning cannot be used)

•

When operation is being coordinated with an older V/f control inverter control system

6

Loading...

Loading...