7.5.6 Protective Functions: L

7-94

J

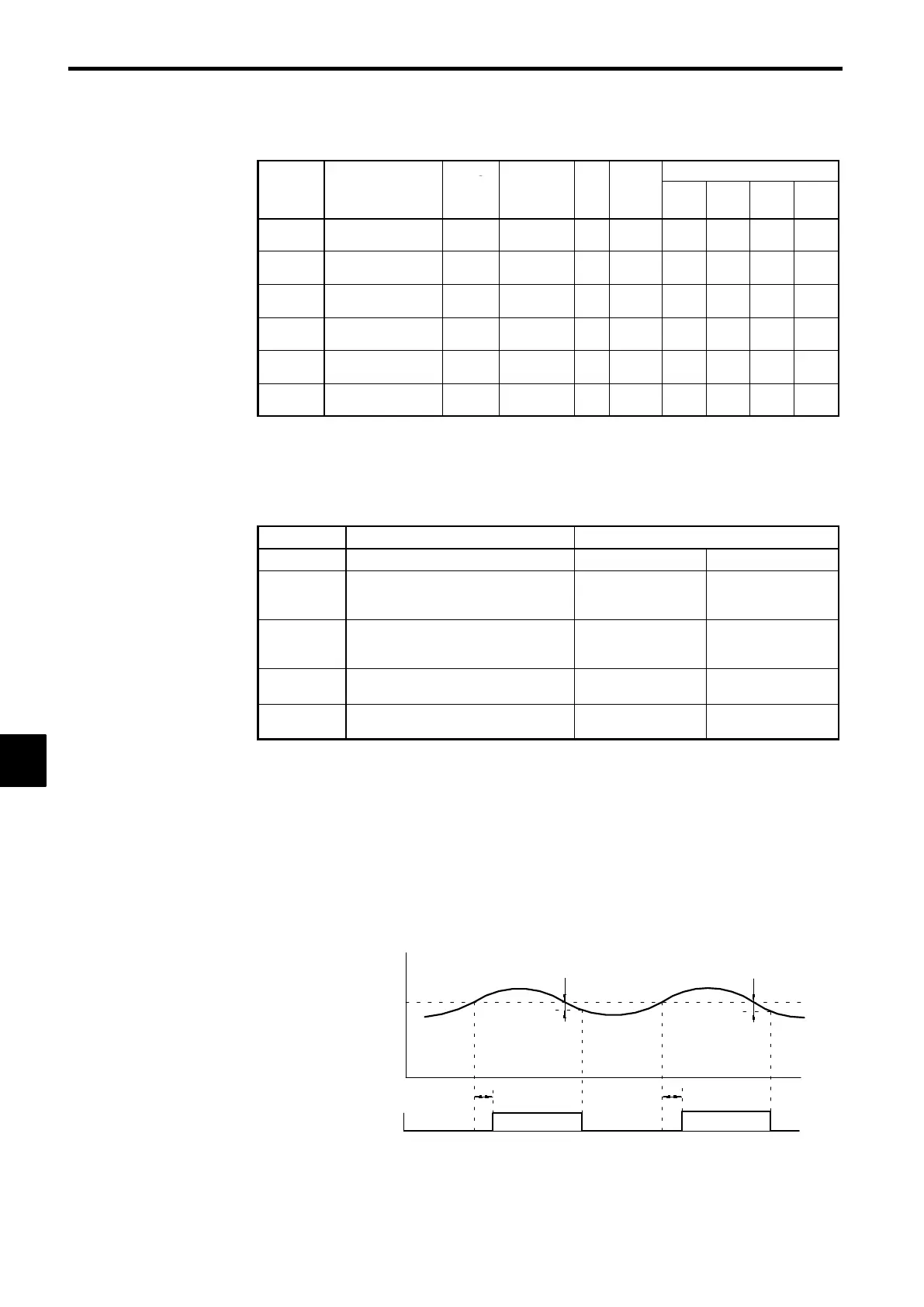

Overtorque Detection Settings: L6-01 to L6-06

User

Change

Valid Access Levels

Constant

Number

Name

during

Opera-

tion

Setting

Range

Unit

Factory

Setting

V/f

Control

V/f with

PG

Open

Loop

Vector

Flux

Vector

L6-01

Torque detection

selection 1

×

0to4 − 0

B B B B

L6-02

Torque detection

level 1

×

0 to 300 % 150

B B B B

L6-03

Torque detection

time 1

×

0.0 to 10.0 s 0.1

B B B B

L6-04

Torque detection

selection 2

×

0to4 − 0

A A A A

L6-05

Torque detection

level 2

×

0 to 300 % 150

A A A A

L6-06

Torque detection

time 2

×

0.0 to 10.0 s 0.1

A A A A

D

The overtorque detection function detects an excessive mechanical load from an increase in the output

current (or output torque).

D

The settings in the torque detection selection constants (L6-01 and L6-04) determine whether overtor-

que conditions will be detected and what kind of processing will be performed if a overtorque condi-

tion is detected.

D

L6-01/L6-04 Settings

Setting Function Display

0

Overtorque detection disabled Overtorque detection 1 Overtorque output 2

1

Detect only during speed agree. Continue

operation even after detection. (Minor

fault)

“OL3” blinks “OL4” blinks

2

Detect overtorque at any time. Continue

operation even after detection. (Minor

fault)

“OL3” blinks “OL4” blinks

3

Detect only during speed agree. Stop out-

put after detection. (Fault

)

“OL3” lights “OL4” lights

4

Detect overtorque at any time. Stop output

after detection. (Fault)

“OL3” lights “OL4” lights

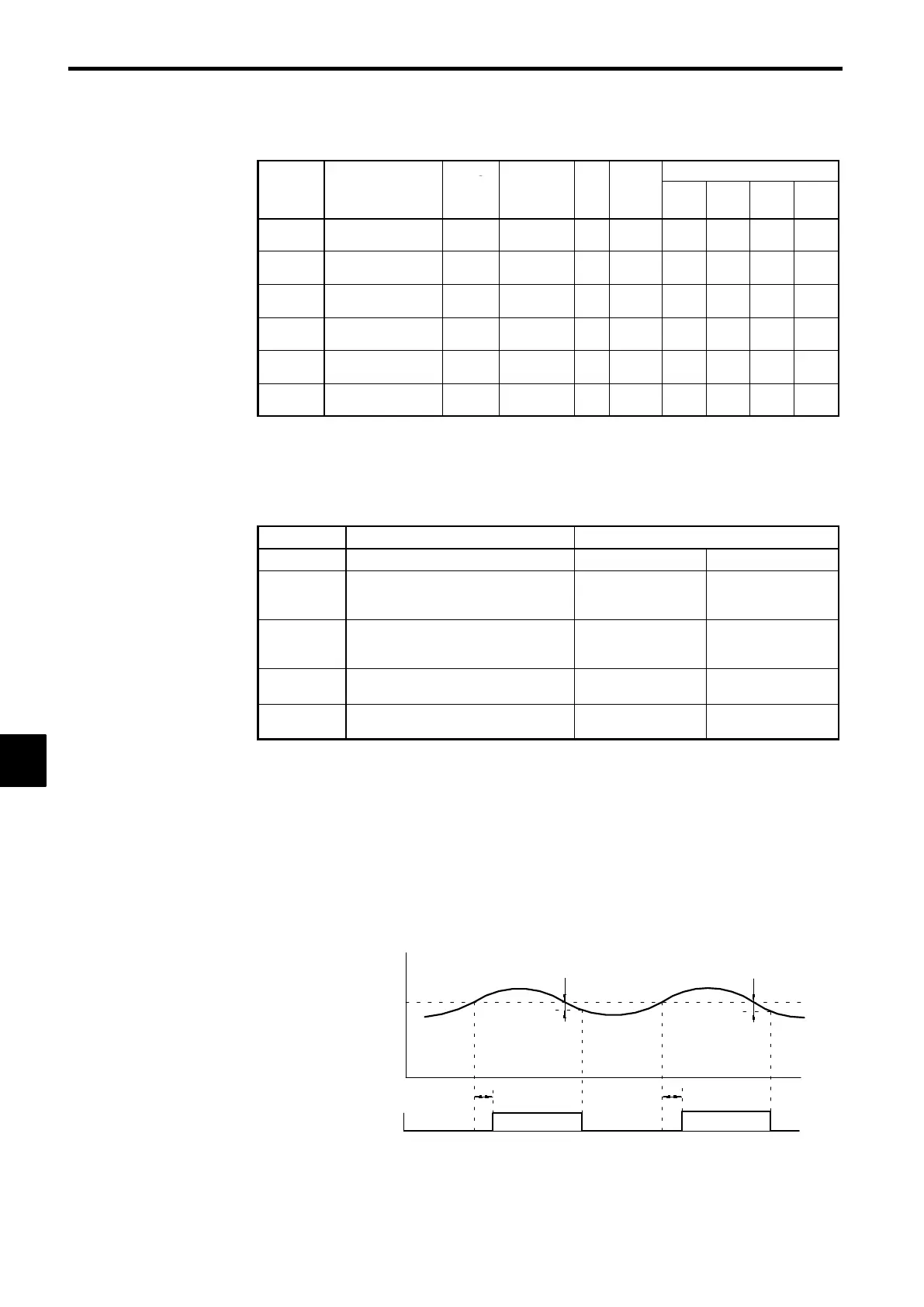

D

When overtorque detection is enabled, be sure to set the overtorque detection level (L6-02 or L6-05)

and the overtorque detection time (L6-02 or L6-05). An overtorque condition is detected when the cur-

rent exceeds the overtorque detection level for longer than the overtorque detection time.

D

The overtorque detection level settings depend on the control method:

•

Open-loop or flux vector control: Set as a percentage of the motor rated torque.

•

Normal V/f or V/f with PG feedback control: Set as a percentage of the Inverter rated current.

D

Any of the following functions can be set in a multi-function output (H2-01, H2-02, or H2-03) to indi-

cate fact that an overtorque condition has been detected.

S

Setting B: Overtorque detection 1 (NO)

S

Setting

18: Overtorque detection 2 (NO)

S Setting 17: Overtorque detection 1 (NC) S Setting 19: Overtorque detection 2 (NC)

Motor current

(Output torque)

L6-02 or L6-05

Overtorque Detection 1 (N.O.)

or Overtorque Detection 2

(N.O.)

ON

L6-03

or

L6-06

::

ON

L6-03

or

L6-06

* The overtorque detection is cleared when the current drops about 5% of the

Inverter’s rated current (or the motor’s rated torque).

Fig 7.51 Timing Chart for Overtorque Detection

7

Loading...

Loading...