7.5.5 External Terminal Functions: H

7-70

•

The current motor selection can be monitored at a multi-function output terminal by setting “1C”

(motor selection monitor) for a constant from H2-01 to 03 (multi-function outputs).

•

Set the Basic (3) or Advanced (4) access level in the initialize setting A1-01 (access level).

•

The constants being used will changed as shown in the following table for the motor switch com-

mand.

Motor Switch command OPEN (motor 1) CLOSED (motor 2)

Control method *

A1-02 (control method in initialize

settings)

E3-01 (motor 2 control method)

V/f characteristics

E1-04 to 13 (V/f characteristics)

E4-01 to 07 (motor 2 V/f character-

istics)

Motor constants

E2-01 to 09 (motor constants)

E5-01 to 06 (motor 2 motor

constants)

Motor selection monitor

OPEN CLOSED

D

When A1-02

≠

E3-01, the constants under 8.2.9 are initialized each time the motor is switched.

D

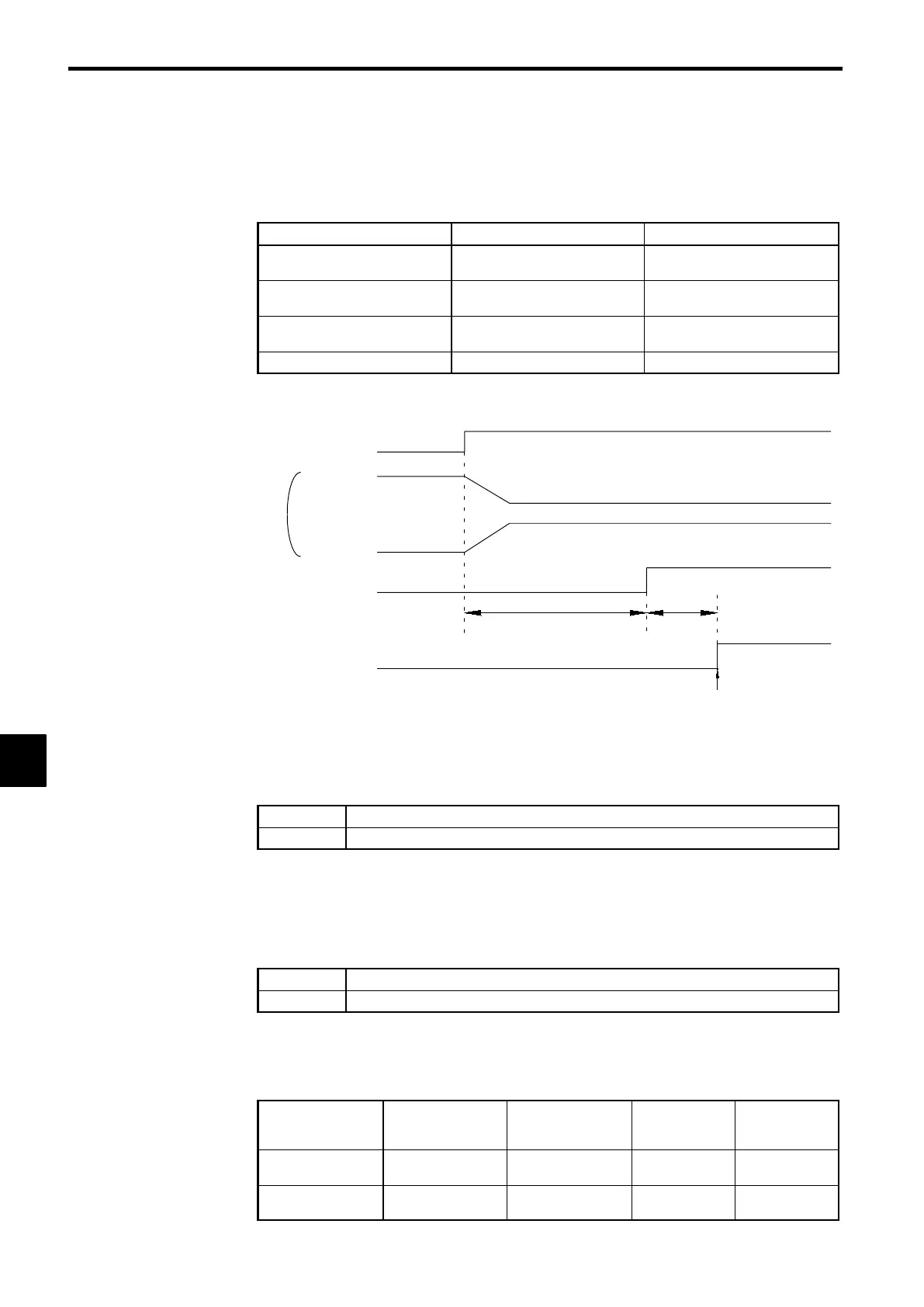

The timing chart for switching between motor 1 and motor 2 is shown below.

Turn ON the Forward (reverse) command only

after confirming the status of the motor selection

monitor.

Motor switching

contactor

(Setting: 1C)

Motor switch command

M1 operation

M2 operation

Motor selection monitor

Forward (reverse)

command

OFF

ON

Approx. 200 ms

Approx.

50 ms

OFF

ON

OFF

ON

OFF ON

OFF

ON

(Approx. 500 ms for control with a PG)

Fig

7.37

Timing Chart for Switching from Motor 1 to Motor 2

PID Control Disable (Setting: 19)

OFF

Enables PID control.

ON

Disables PID control. (Normal Inverter control)

D

With this setting, the multi-function input switches between PID control and normal Inverter control.

This function can be used to perform trial operation or jog operation with normal inverter control

(open-loop control) and then switch to PID control (closed-loop control using feedback) after adjust-

ing the system. The PID disable function can also be used to switch to open-loop control when there

is a problem with the feedback value.

Constants Write Enable (Setting: 1B)

OFF

Write-protects all constants except for frequency monitor.

ON

Allows constants specified in Initialize mode to be changed.

D

With this setting, the multi-function input can be used to write-protect the Operator constants. When

the input is OFF, the Operation mode frequency can be monitored and the frequency can be changed

but other changes are prohibited.

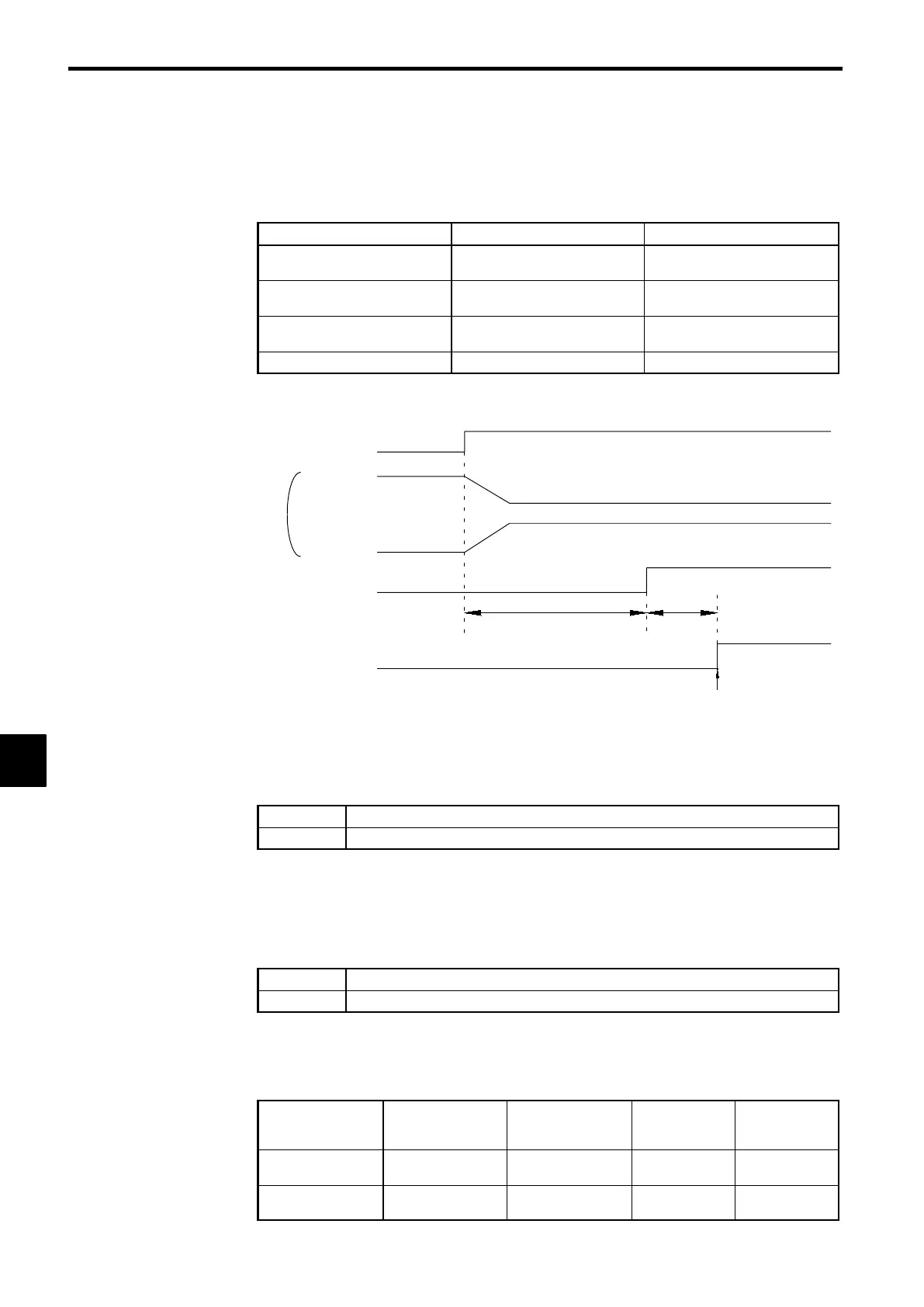

Trim Control Increase and Decrease (Settings: 1C and 1D)

Output frequency

Reference frequency

+ trim control level

(d4-02)

Reference frequency −

trim control level

(d4-02)

Reference fre-

quency

Reference fre-

quency

Trim Control In-

crease

ON OFF ON OFF

Trim Control De-

crease

OFF ON ON OFF

7

Loading...

Loading...