6.3.2 V/f Pattern Selection: E1-03

6-22

6.3.2 V/f Pattern Selection: E1-03

User

Change

Valid Access Levels

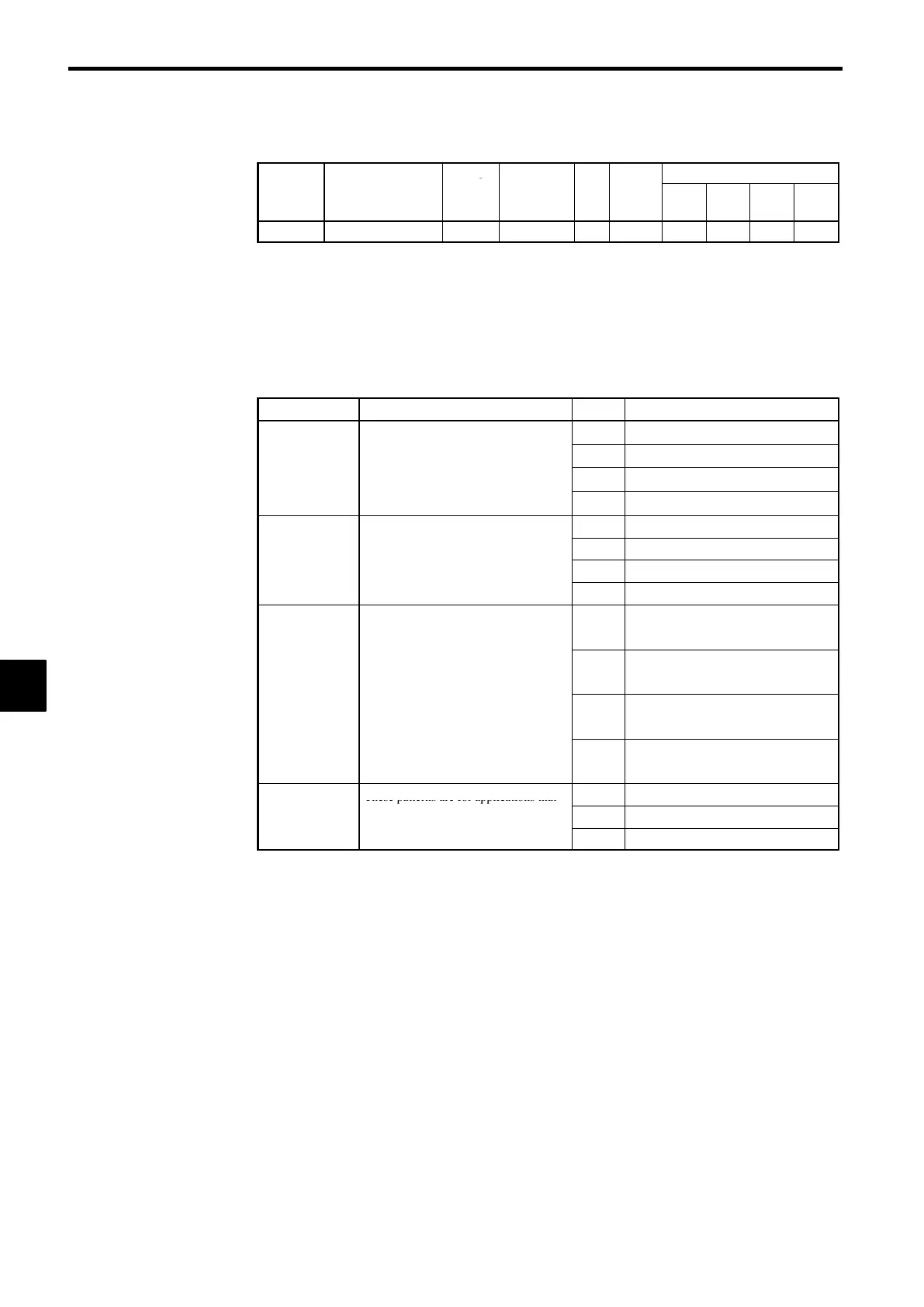

Constant

Number

Name

during

Opera-

tion

Setting

Range

Unit

Factory

Setting

V/f

Control

V/f with

PG

Open

Loop

Vector

Flux

Vector

E1-03

V/f pattern selection

×

0toF − F

Q Q

× ×

D

The V/f pattern can be set to any of the following:

• One of 15 preset patterns (settings 0 through E)

• A custom user-set pattern (setting F)

D

The factory setting for E1-03 is “F” (user-defined V/f pattern), but the default contents of this setting

are the same as setting “1.”

J

Selecting a Preset V/f Pattern: E1-03 = “0” through “E”

D

Refer to the following table to set one of the 15 preset patterns.

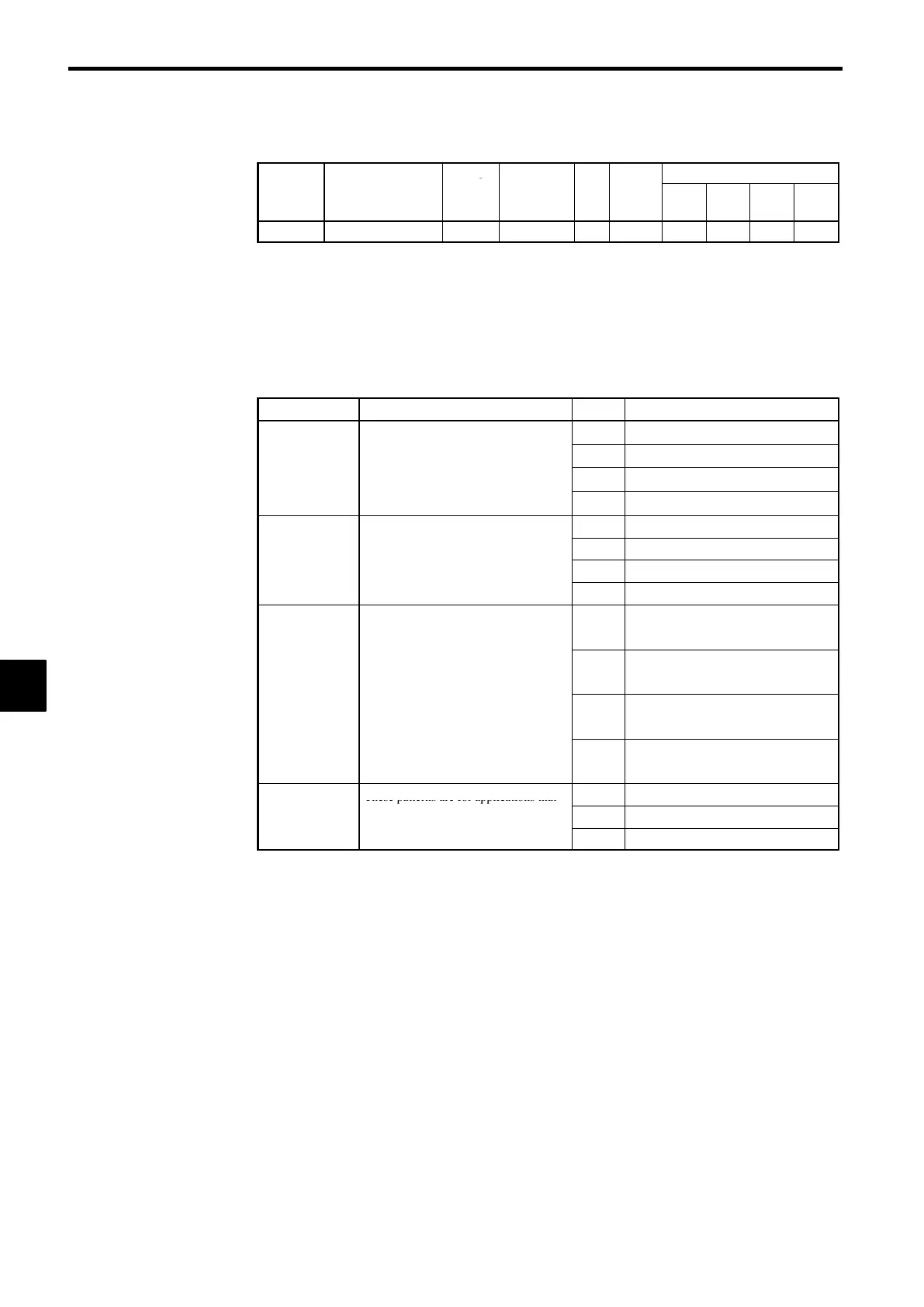

Characteristics Applications Setting Specifications

These patterns are for general-purpose

0 50 Hz

applications.

Use these

atterns when the load tor

ue

1 60 Hz

Fixed torque

is to remain constant for any rotational

-

-

2 60 Hz, Voltage saturation at 50 Hz

spee

, suc

as

n stra

g

t-

ne convey-

ors.

3 72 Hz, Voltage saturation at 60 Hz

4 50 Hz, cubic

Use these patterns when there is a qua-

dratic or cubic relationshi

between the

5 50 Hz, quadratic

Variable torque

rotational speed and load, such as in

6 60 Hz, cubic

ans or pumps.

7 60 Hz, quadratic

Select a high starting torque V/f pattern

only in the following cases:

8 50 Hz, low starting torque

High starting

S The wiring distance between the In-

verter and motor is relatively large

(greater than 150 m).

9 50 Hz, high starting torque

torque*

S A large torque is required at startup

(such as for heavy axis loads).

S An AC or DC reactor is connected to

A 60 Hz, low starting torque

the Inverter ’s input or output.

S A motor less than the maximum appli-

cable motor is being used.

b 60 Hz, high starting torque

These patterns are for applications that

C 90 Hz, Voltage saturation at 60 Hz

High-speed op-

must rotate at frequencies greater than

-

d 120 Hz, Voltage saturation at 60 Hz

z.

x

v

-

quencies greater than 60 Hz.

E 180 Hz, Voltage saturation at 60 Hz

* Normally it isn’t necessary to use these patterns because starting torque is ensured by auto-

matic torque boost functions.

D

The constant settings for E1-04 through E1-10 will be changed automatically when one of these pat-

terns is selected. There are three possible settings for these constants depending on the Inverter’s ca-

pacity:

• A 0.4 to 1.5 kW V/f pattern

• A 2.2 to 45 kW V/f pattern

• A 55 to 300 kW V/f pattern

D

The characteristics for these patterns are shown in the diagrams on the following pages.

6

Loading...

Loading...