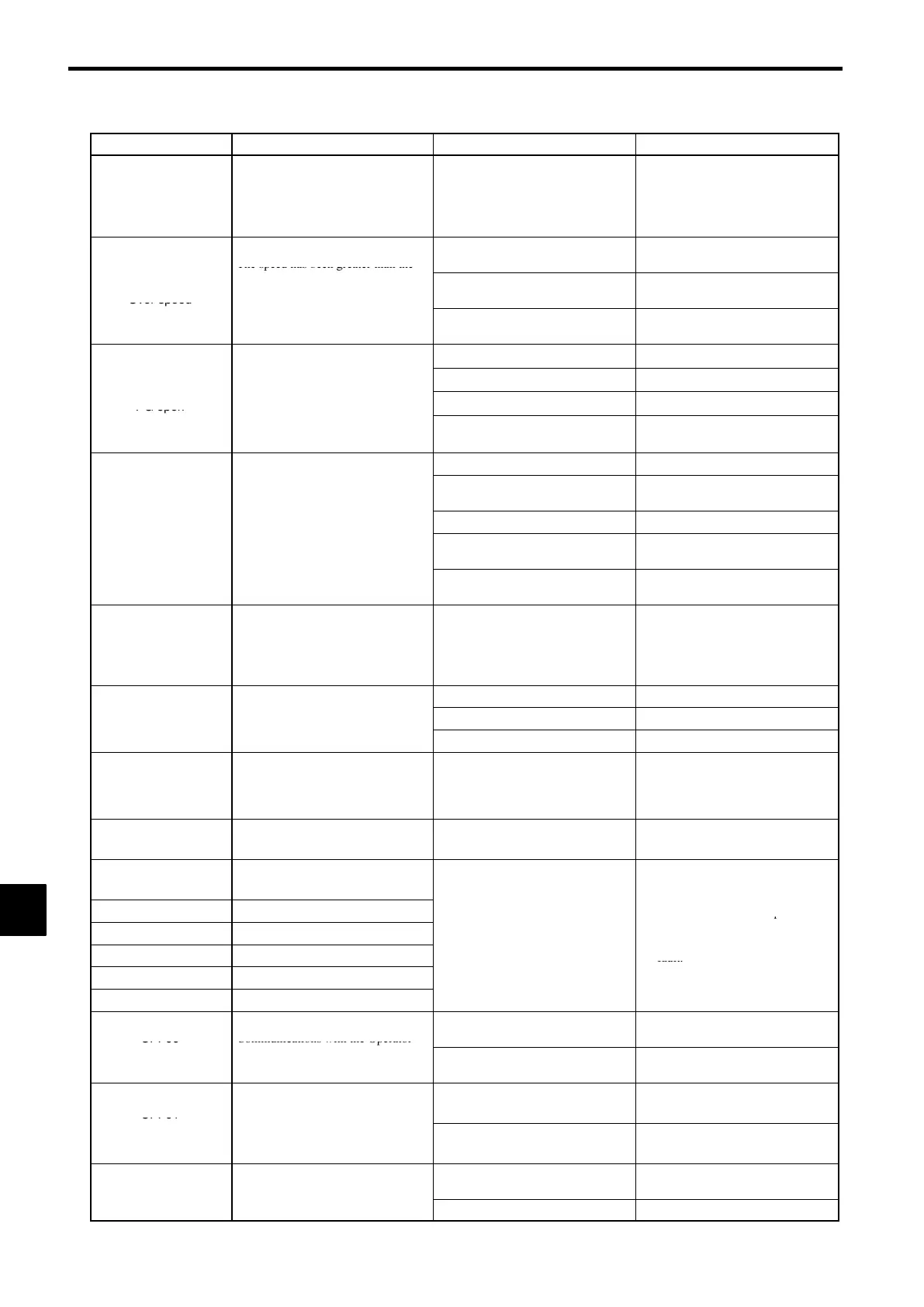

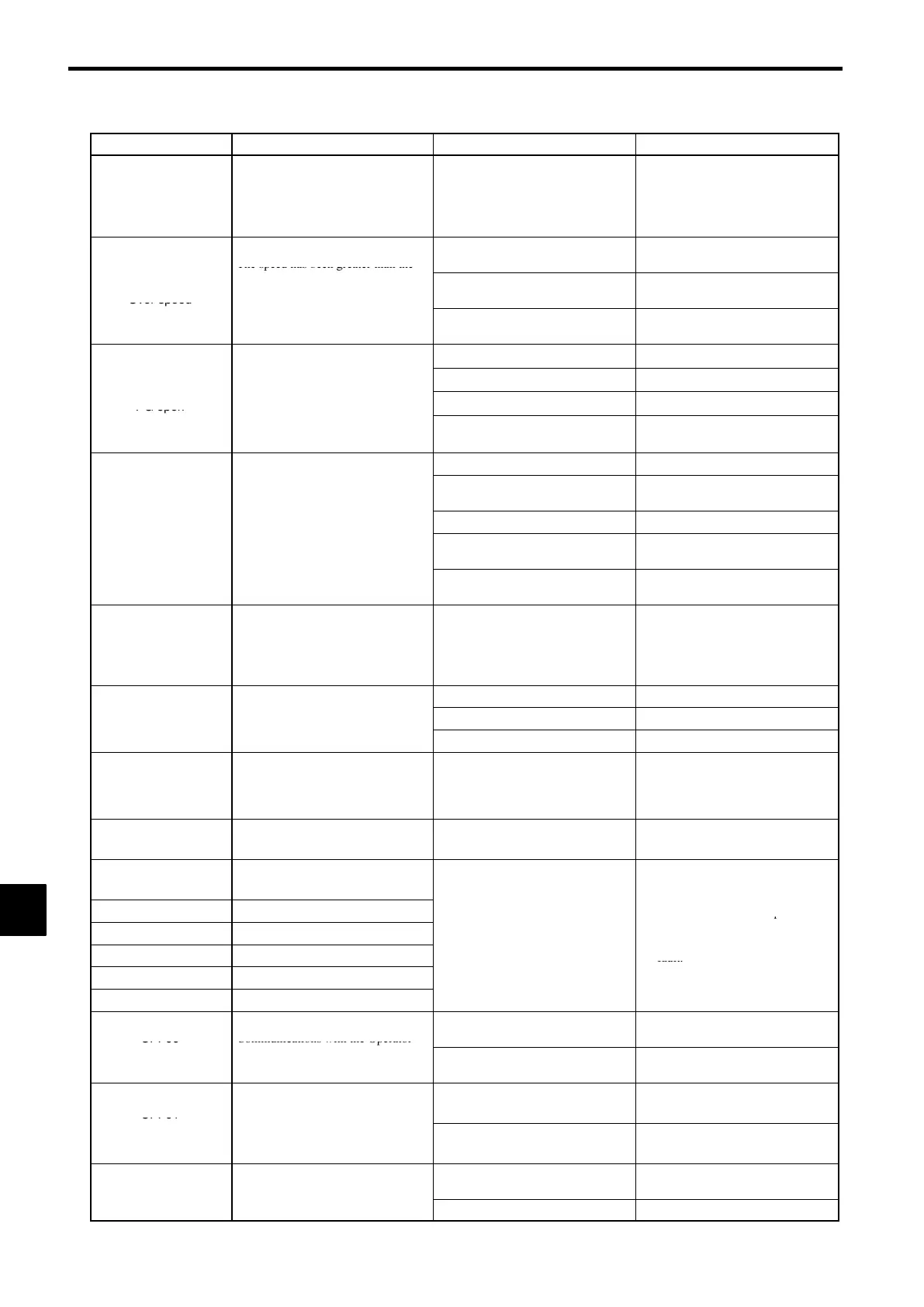

Troubleshooting

9.1.1 Fault Detection

9-4

Fault Display Corrective ActionsProbable CausesMeaning

OL4

Overtorque det 2

Overtorque 2

There has been a current greater than

the setting in L6-05 for longer than

the setting in L6-06.

---

S

Make sure that the current setting in

L6-05 and time setting in L6-06 are

appropriate.

S

Check the mechanical system and

correct the cause of the overtorque.

Overspeed

The speed has been greater than the

Overshooting/Undershooting are oc-

curring.

Adjust the gain again.

OS

Over speed

setting in F1-08 for longer than the

setting in F1-09.

The reference speed is too high.

Check the reference circuit and refer-

ence gain.

The settings in F1-08 and F1-09

aren’t appropriate.

Check the settings in F1-08 and

F1-09.

PG Disconnection Detected

There is a break in the PG wiring. Fix the broken/disconnected wiring.

PG pulses aren’t being input due to

the followin

conditions:

The PG is wired incorrectly. Fix the wiring.

PG open

The status has exceeded F1-14 time.

Power isn’t being supplied to the PG. Supply power to the PG properly.

Flux vector: Soft start output ≥ 2%

Flux V/f: Soft start output ≥ E1-09

---

Check for open circuit when using

brake (motor).

Excessive Speed Deviation

The load is too heavy. Reduce the load.

After the actual (motor) speed and the

reference speed agree (depending on

−

-

The acceleration time and decelera-

tion time are too short.

Lengthen the acceleration time and

deceleration time.

DEV

−

,

-

ation changes so it is greater than the

The load is locked. Check the mechanical system.

Speed Deviation

setting in F1−10 for longer than the

setting in F−11.

The settings in F1-10 and F1-11

aren’t appropriate.

Check the settings in F1-10 and

F1-11.

---

Check for open circuit when using

brake (motor).

CF

Out of Control

Control Fault

The torque limit was reached contin-

uously for 3 seconds or longer during

a deceleration stop during open-loop

vector control.

--- Check the motor constants.

Zero Servo Fault

The torque limit is too small. Increase the limit.

SVE

The rotation position moved during

The load torque is too large. Reduce the load torque.

ero

ervo

au

.

--- Check for signal noise.

OPR

Oper Disconnect

Operator Connection Fault

The Operator was disconnected dur-

ing operation started by a run com-

mand from the Operator.

--- Check the Operator connection.

EF0

Opt External Flt

External fault input from Transmis-

sion Option Card.

---

Check the Transmission Option Card

and transmission signal.

EF3

External Fault 3

External fault (Input terminal 3)

EF4 External fault (Input terminal 4)

S

Reset external fault inputs to the

EF5 External fault (Input terminal 5)

An “external fault” was input from a

-

multi-function inputs.

EF6 External fault (Input terminal 6)

mu

-

unc

on

npu

.

S

Remove the cause of the external

fault.

EF7 External fault (Input terminal 7)

EF8 External fault (Input terminal 8)

CPF00

Operator Communications Error 1

Communications with the Operator

The Digital Operator’s connector isn’t

connected properly.

Disconnect the Digital Operator and

then connect it again.

COM-ERR (OP&INV)

were not established within 5 seconds

after the power was turned on.

The Inverter’s control circuits are

faulty.

Replace the Inverter.

CPF01

Operator Communications Error 2

After communications were estab-

The Digital Operator isn’t connected

properly.

Disconnect the Digital Operator and

then connect it again.

COM-ERR (OP&INV)

lished, there was a transmission error

with the Digital Operator for more

than 2 seconds.

The Inverter’s control circuits are

faulty.

Replace the Inverter.

CPF02

Baseblock circuit error

---

Try turning the power supply off and

on again.

BB Circuit Err

The control circuit is damaged. Replace the Inverter.

9

Loading...

Loading...