3

Module Specifications

3.4.2

Counter Functions and Settings of LIO-01/LIO-02 Modules

3-42

4.

Find the load travel distance for each rotation of the load axis using the reference unit

and set this distance to the counter fixed parameter No. 18 (Moving Amount Per

Machine Rotation).

• Calculation Examples

• For a ball screw pitch of

5 mm and a reference unit of 0.001 mm:

(Reference unit)

5.

Set the Encoder Gear Ratio and the Machine Gear Ratio in the counter fixed

parameters No. 11 and No.12.

When the encoder axis has rotated m times and the mechanical configuration allows the load

axis to rotate n times, set the following values:

No. 11 (Encoder Gear Ratio) = m rotations

No. 12 (Machine Gear Ratio) = n rotations

Setting range: 1 to 65,535 [rotations]

<Setting Example>

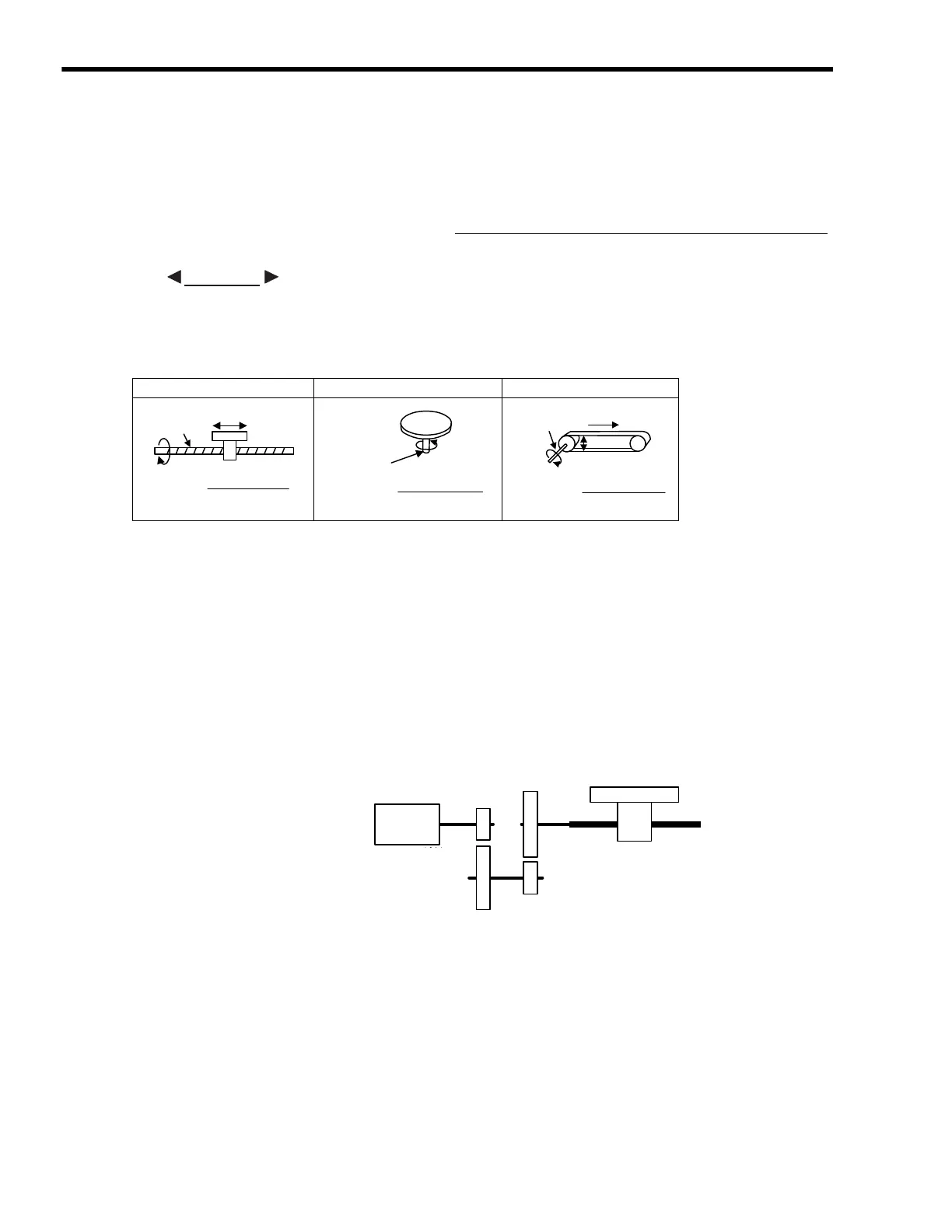

For the configuration shown in the diagram:

Gear ratio = n/m = (3/7)

×

(4/9) = 4/21

Therefore, set the following values:

No.11 (Encoder Gear Ratio)

= 4 (rotations)

No. 12 (Machine Gear Ratio)

= 21 (rotations)

Load travel distance per load axis rotation reference unit

Reference unit

Load travel distance per rotation of

load axis (reference unit)

=

EXAMPLE

5

0.001

------------- 5000=

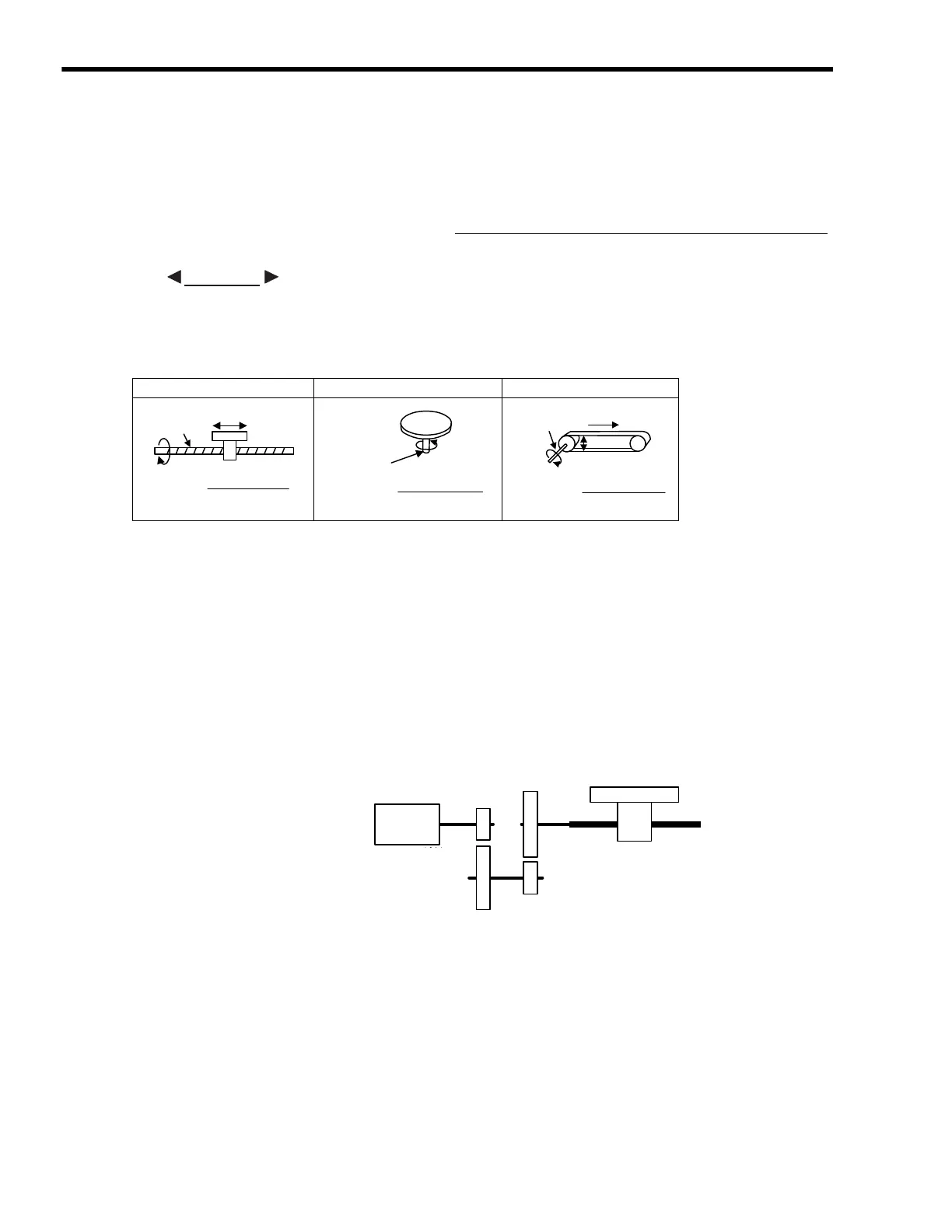

Ball screw Round table

Belt

+ pulley

P

One

rotation

P

Reference unit

=

Load axis

P: Pitch

360°

Reference unit

Load axis

One

rotation

=

Reference unit

Load axis

D: Pulley diameter

D

πD

=

π

D

One

rotation

エンコーダ軸

m回転

7回転

3回転

9回転

4回転

負荷軸

n回転

Encoder axis

m rotations

7 rotations

4 rotations

9 rotations

3 rotations

Load axis n rotations

Loading...

Loading...