12

Maintenance and Inspection

12.1.1

Daily Inspections

12-2

12.1 Inspection Items

This section summarizes daily and regular inspection items that must be performed by the

customer.

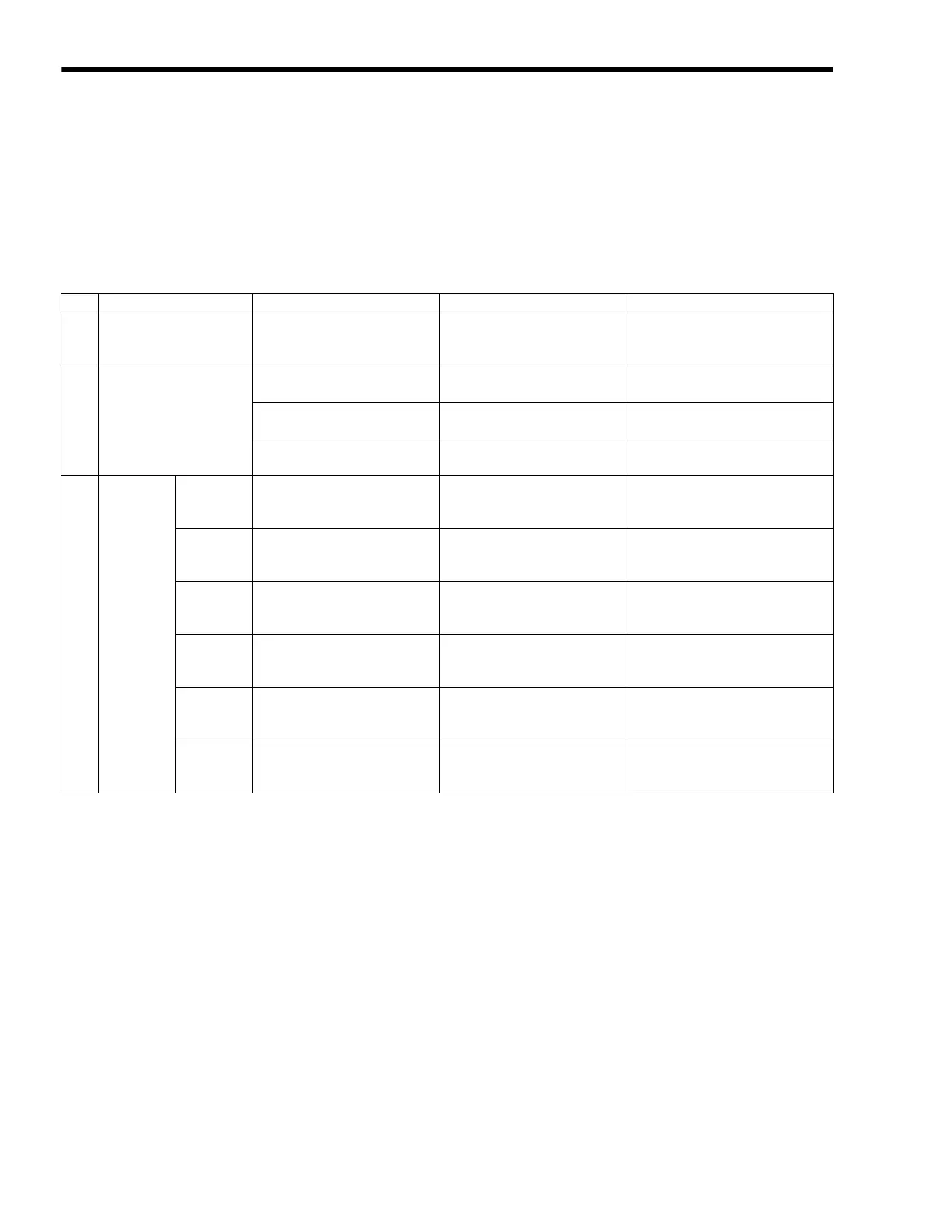

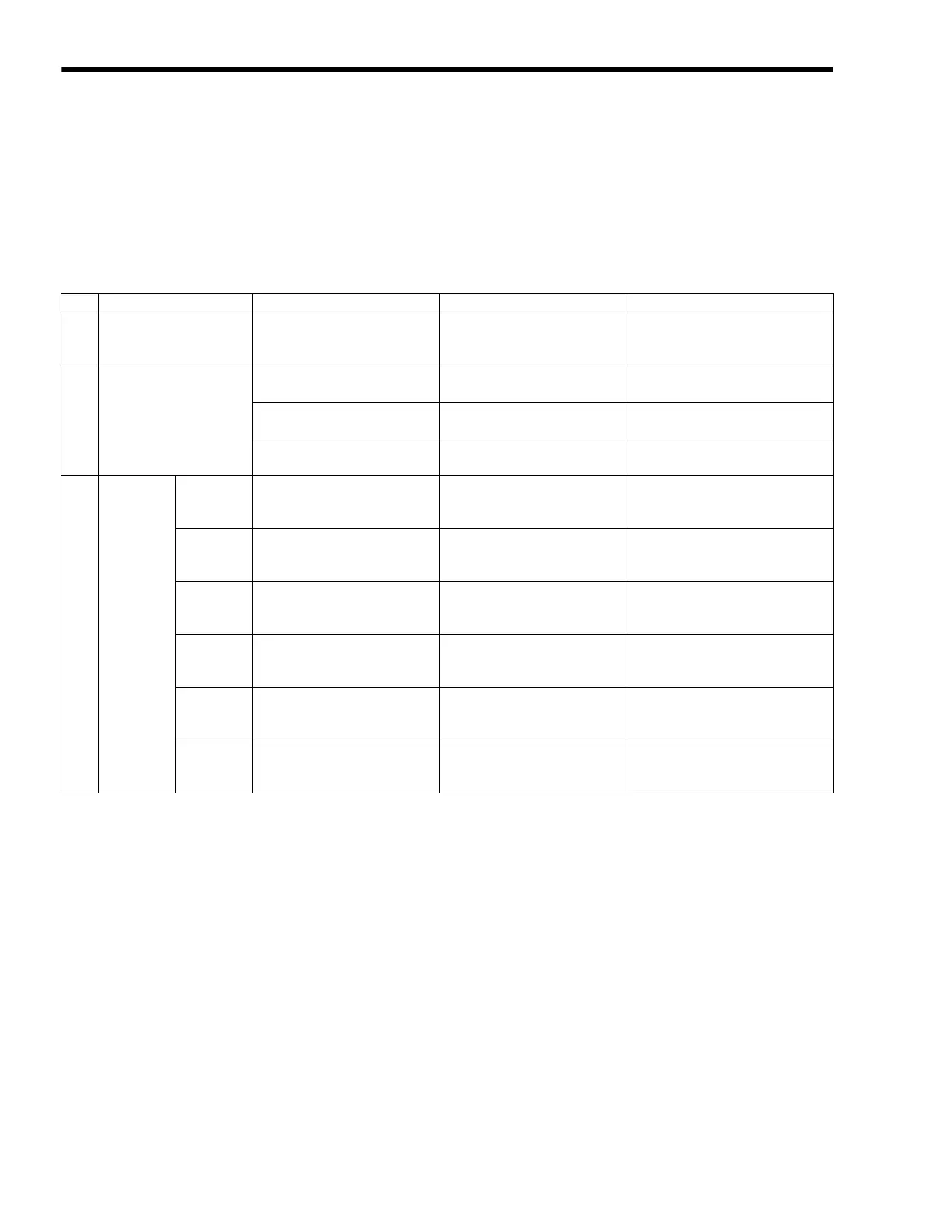

12.1.1 Daily Inspections

The following table lists the daily inspection items.

No. Inspection Item Inspection Details Criteria Action

1

Installation conditions of

Module, etc.

Check the mounting screws for

looseness. Check whether the

covers are all in place.

The screws and covers must be

secured correctly.

Retighten the screws.

2

Connection conditions

Check the terminal screws for

looseness.

The screws must be tight. Retighten the screws.

Check the connectors for

looseness.

The connectors must be tight. Retighten the connector set screws.

Check the gap between crimp

terminals.

There must be an appropriate

gap between the terminals.

Correct as necessary.

3

Indicators

RDY

Check whether the indicator is

lit.

The indicator must be lit. (It is

abnormal if the indicator is not

lit.)

Refer to 12.3 Troubleshooting on

page 12-5.

RUN

Check whether the indicator is lit

while the system is in RUN

state.

The indicator must be lit. (It is

abnormal if the indicator is not

lit.)

Refer to 12.3 Troubleshooting on

page 12-5.

ERR

Check whether the indicator is

not lit.

The indicator must be not lit. (It

is abnormal if the indicator is

lit.)

Refer to 12.3 Troubleshooting on

page 12-5.

ALM

Check whether the indicator is

not lit.

The indicator must be not lit. (It

is abnormal if the indicator is

lit.)

Refer to 12.3 Troubleshooting on

page 12-5.

TX

Check whether the indicator

lights during communication.

The indicator must be lit. (It is

abnormal if the indicator is not

lit.)

Refer to 12.3 Troubleshooting on

page 12-5.

BAT

Check whether the indicator is

not lit.

The indicator must be not lit.

(The battery voltage is too low if

the indicator is lit.)

Replace the battery.

Loading...

Loading...