SECTION 58 - ATTACHMENTS / HEADERS - CHAPTER 3

58-20

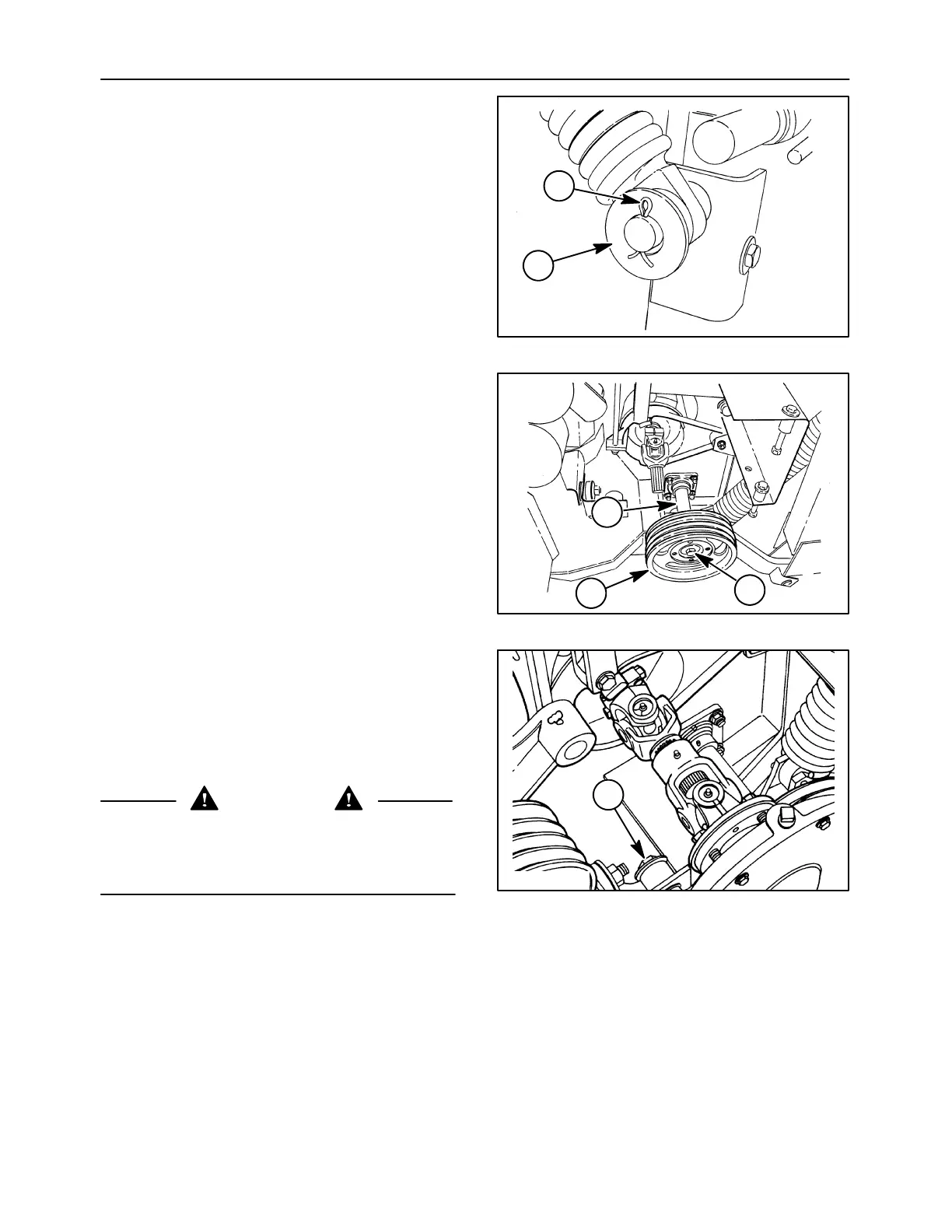

7. Reinstall the flotation spring by aligning the lower

spring mount with the brackets on the lift arm.

Insert the clevis pin, flat washer, 1, and retain

using a cotter pin, 2. Retighten the flotation

spring as required to provide correct header

flotation on the right side of the header.

19992631

1

2

51

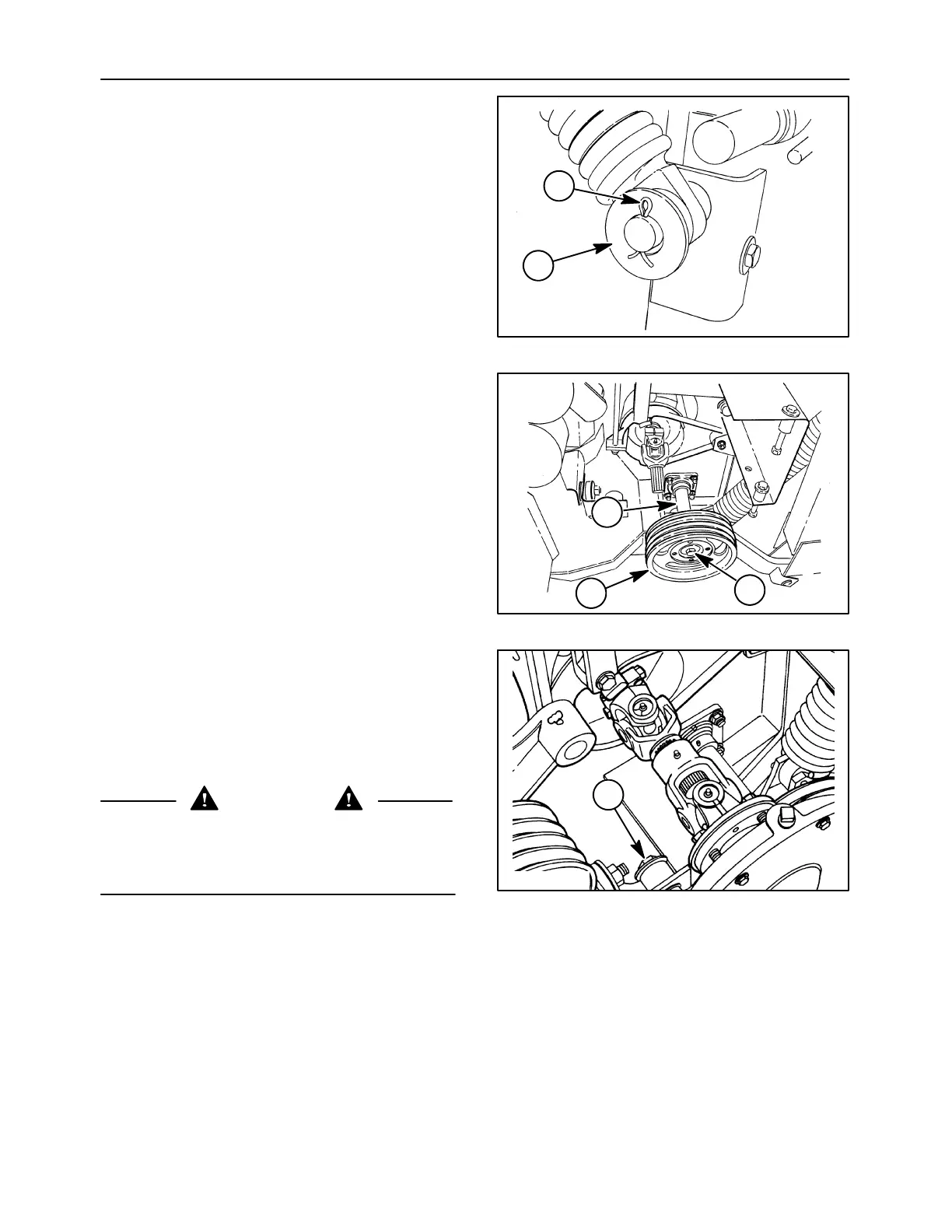

8. Slide the drive sheave, 1, over the left end of the

conditioner roll shaft, 2, and install the thick flat

washer and 3/4″ x2″ cap screw, 3. Block the

conditioner rolls, using a block between the rolls,

or a bar through the upper roll U-joint. Tighten the

cap screw to 397 Nám (293 ft-lb) and then drive

the sheave onto the shaft using a deadblow or

soft-faced hammer. Retorque the cap screw.

Repeat this process until the cap screw no longer

loosens up when the sheave is struck.

19992640

1

2

3

52

9. The conditioner roll gearbox is easier to install if

one person holds the gearbox up to the side of

the unit while a second person installs the

retaining hardware.

Lift the conditioner roll gearbox up to the side of

the unit and rest the lower shaft flange inside the

lower roll sheave.

CAUTION

The conditioner roll gearbox is heavy and

awkward.Use caution not to drop the gearbox,as

personal injury or damage to the gearbox may

result.

Slip the cap screw, 1, through the upper gearbox

mount to support the gearbox.

A3662-1

1

53

Loading...

Loading...