Needle bar

Service Instructions 755 A/756 A - 00.0 - 02/2019 49

2. Slide the needle bar linkage (7) onto the shaft (8) as far as it will go.

3. Turn the handwheel until the screw (14) can be accessed through the

arm shaft crank.

4. Tighten the screw (14).

5. The pin (4) must be seated in the arm shaft crank (9) such that the

screws (10) can be tightened on the face of the pin (4).

6. Tighten the screws (10).

7. Slide the thread lever (6) back into the slot in the machine casting.

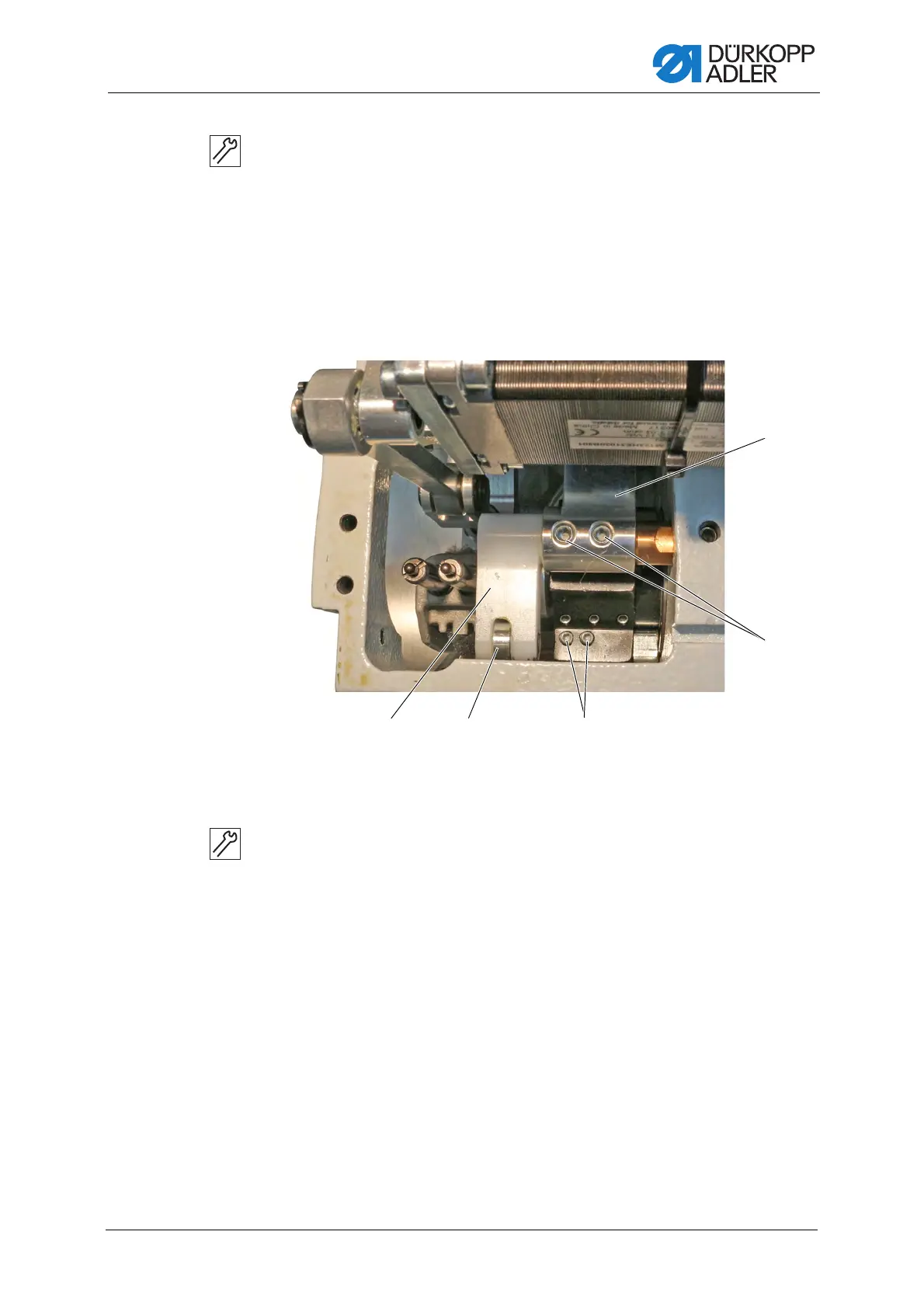

Fig. 43: Assembling the needle bar linkage (3)

8. Push the bolt (5) completely into lever (11).

9. Push the bolt (5) further into lever (13).

10. Tighten the screws (12).

The thread lever (6) must be able to move freely.

The thread lever (6) is automatically positioned correctly when the

screws (10) on the face of the pin (4) have been tightened.

11. Slightly loosen the screws (10) and slowly complete 2-3 turns at the

handwheel.

The components are released from tension mechanically.

12. Tighten the screws (10).

13. Tie the oil wick (3) to the felt (2).

(6) - Thread lever

(10) - Screws

(11) - Lever

(12) - Screws

(13) - Lever

Loading...

Loading...