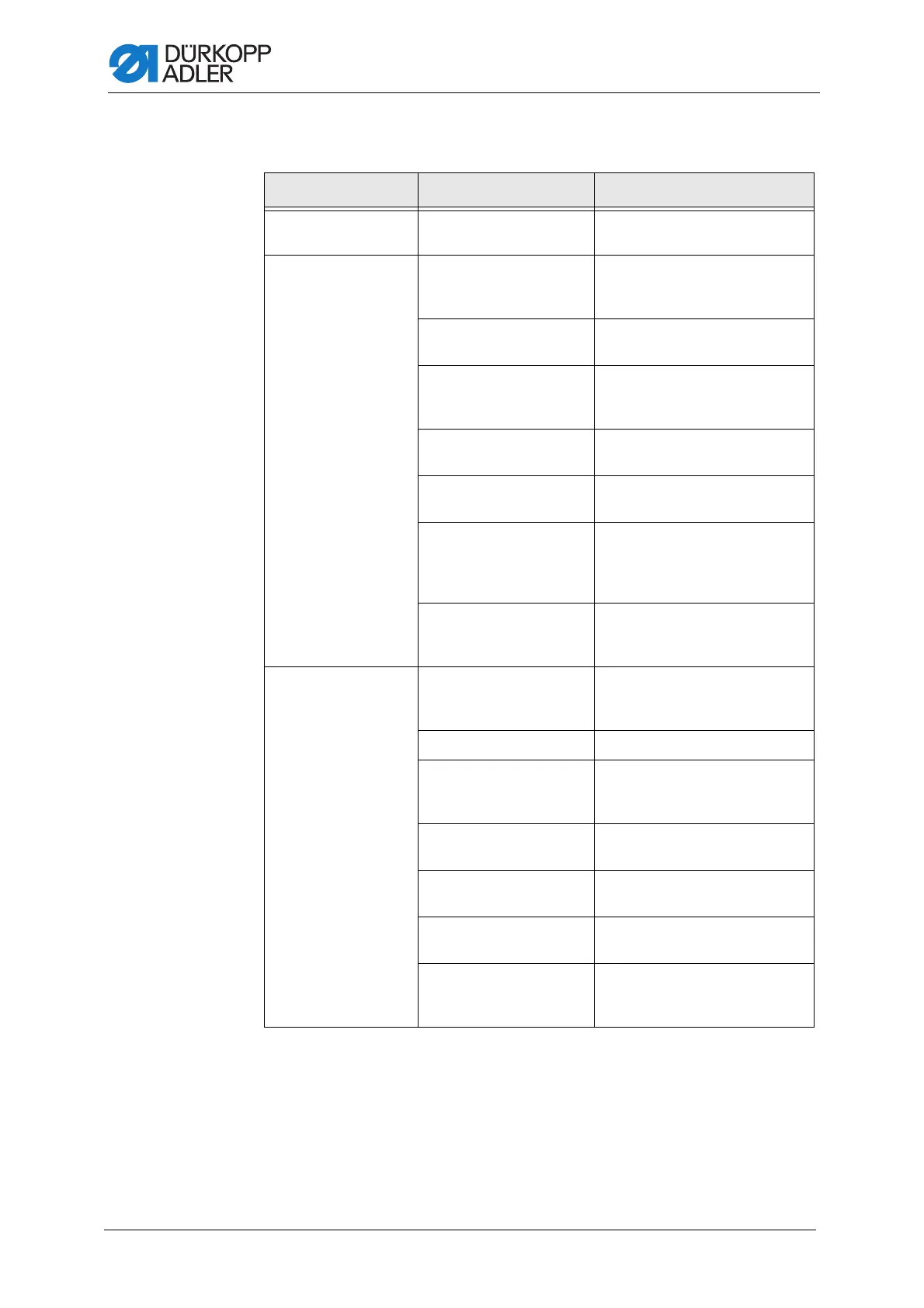

Troubleshooting

220 Service Instructions M-TYPE DELTA - 00.0 - 12/2019

23.3 Errors in sewing process

Error Possible causes Remedial action

Unthreading at seam

beginning

Needle thread tension is

too firm

Check needle thread tension

Thread breaking Needle thread and hook

thread have not been

threaded correctly

Check threading path

Needle is bent or sharp-

edged

Replace needle

Needle is not inserted

correctly into the needle

bar

Insert the needle correctly into

the needle bar

The thread used is

unsuitable

Use recommended thread

Thread tensions are too

tight for the thread used

Check thread tensions

Thread-guiding parts, such

as thread tube, thread

guide or thread take-up

disk, are sharp-edged

Check threading path

Throat plate, hook or

spread have been

damaged by the needle

Have parts reworked by qualified

specialists

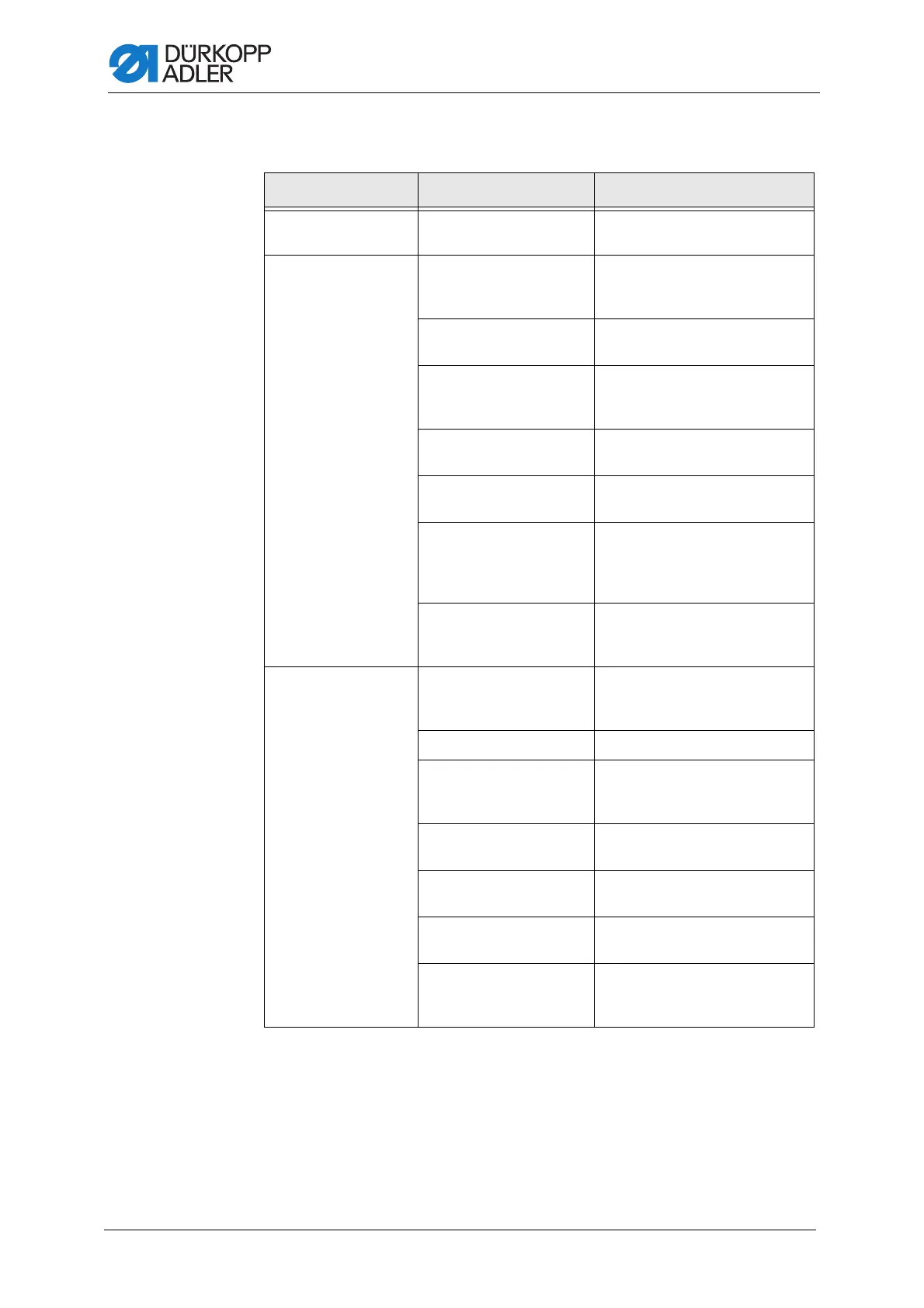

Skip stitches Needle thread and hook

thread have not been

threaded correctly

Check threading path

Needle is blunt or bent Replace needle

Needle is not inserted

correctly into the needle

bar

Insert the needle correctly into

the needle bar

The needle thickness used

is unsuitable

Use recommended needle

thickness

The reel stand is

assembled incorrectly

Check the assembly of the reel

stand

Thread tensions are too

tight

Check thread tensions

Throat plate, hook or

spread have been

damaged by the needle

Have parts reworked by qualified

specialists

Loading...

Loading...