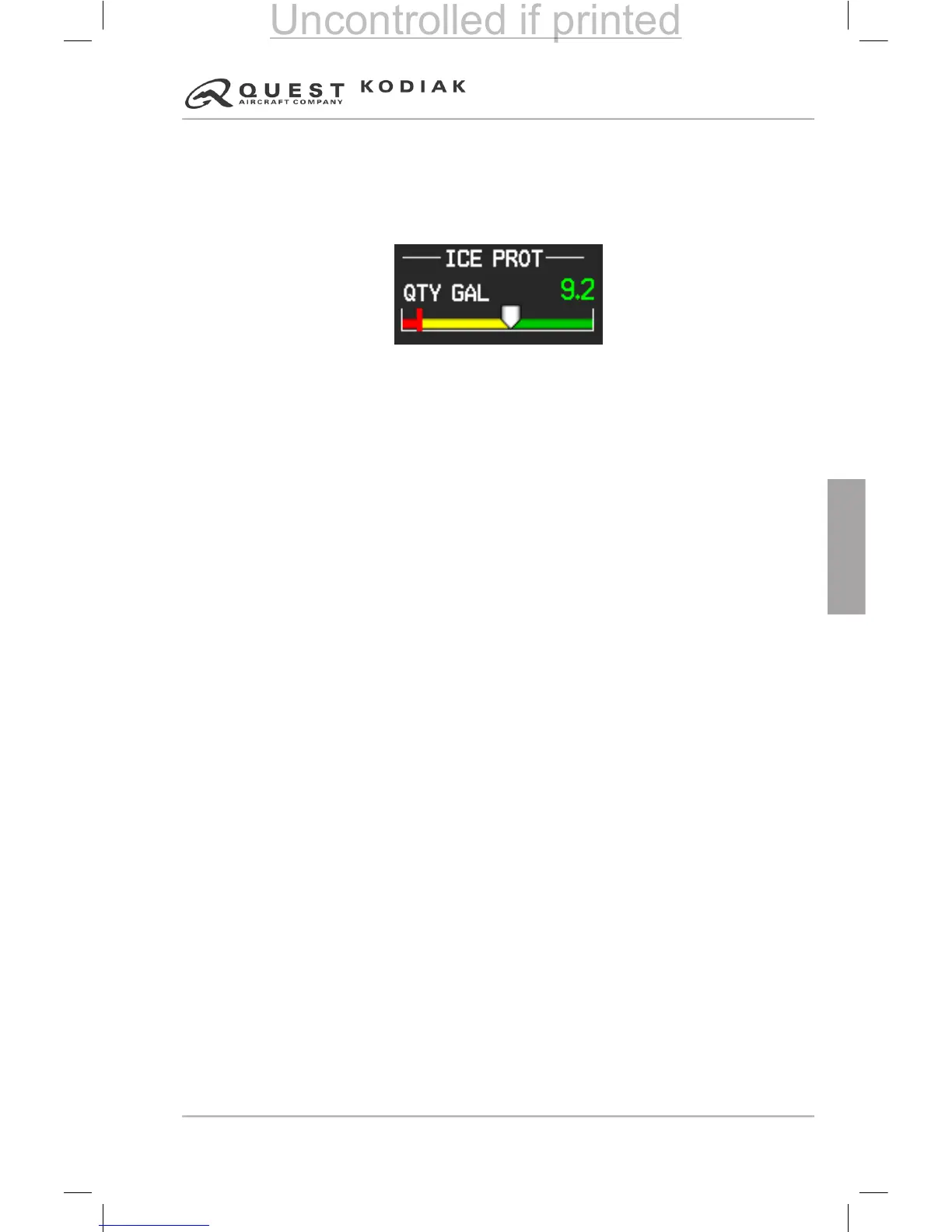

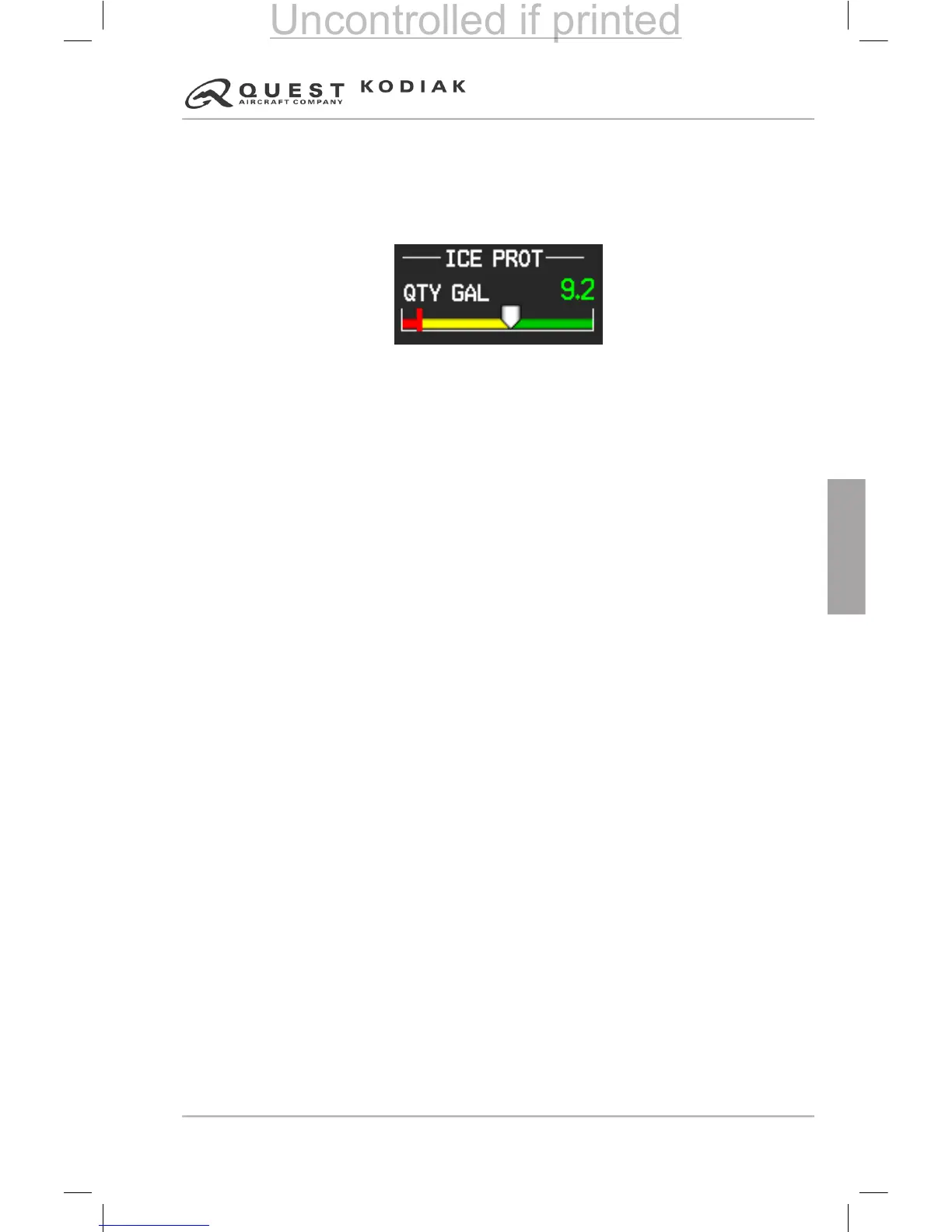

FLUID QUANTITY INDICATION

The TKS uid quantity indication is provided through the G1000 on the

Engine Indication System (EIS) on the SYSTEM page. Fluid quantity is

measured by a oat type quantity sensor installed in the ice protection uid

tank.

Figure 9.4-2 – Fluid Quantity Indicator

MODES OF OPERATION

The system is designed for ight into known icing conditions, as dened

by 14 CFR Part 23 and for use in continuous maximum and maximum

intermittent icing envelopes, as dened by 14 CFR Part 25, Appendix C

(for IAC AR certied airplanes, IAC AR Aviation Regulations Part 25,

Appendix C). The HIGH mode provides 100% anti-icing protection to all

leading edge surfaces for all conditions found in the Maximum Continuous

Icing Envelope. NORMAL mode produces cycled ow 30 seconds on and 90

seconds off. During the 30 seconds on time, the ow rate is two times that

of the HIGH mode, but since it runs on a 25% duty cycle, total uid usage

is 50% of the HIGH ow setting. MAXIMUM has two times the ow rate of

HIGH mode and therefore has 200% of the anti-ice ow needed to provide

a clean leading edge in the Maximum Continuous Icing Envelope. BACKUP

mode is the equivalent of HIGH mode, but uses a separate pump than the

HIGH mode.

ICE INSPECTION LIGHTS

To provide visual verication of icing conditions and conrmation of uid

ow, ice inspection lights are ush mounted to the right and left crew doors.

The ice inspection lights illuminate the leading edge of the wings, pitot/static

tubes, stall warning lift transducer, and the upper portion of the wing struts.

System components include the LED light assemblies and a two position

switch labeled ICE LIGHT.

The ice inspection lights operate on 28 VDC and are protected by the 5 amp

circuit breaker labeled ICE INSP LIGHTS. The ice inspection lights switch is

located on the right hand side switch panel.

Loading...

Loading...