Malfunctions in driving mode

8.5 Emergency operation and breakdown assistance

8 - 34 3 302 736 en Operating manual

GMK4090

xx.xx.xxxx

Removing a dam-

aged wheel

• Switch off the suspension; à p. 5 - 17.

• Raise the truck crane with the outriggers until the wheel to be changed

just barely leaves the ground.

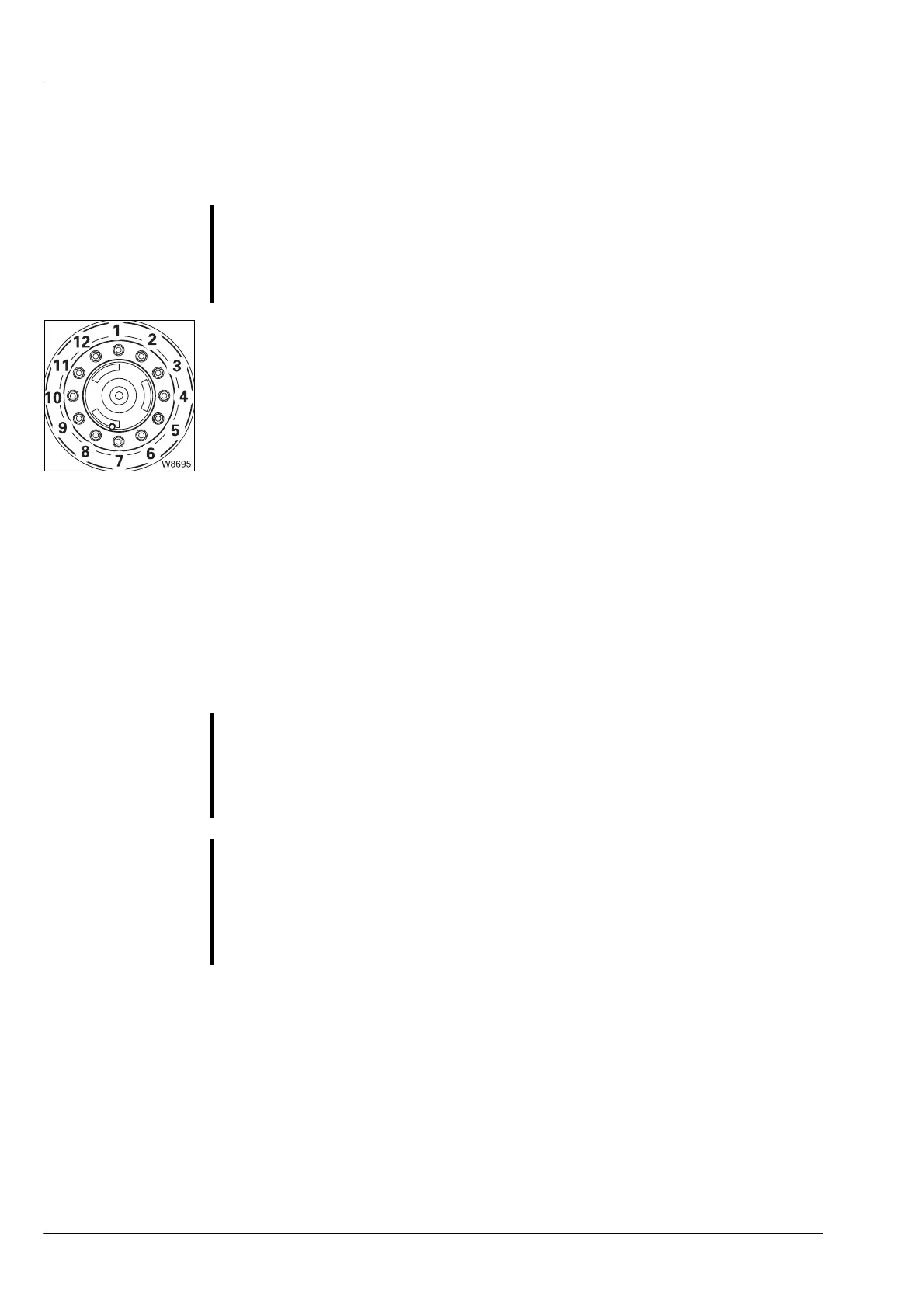

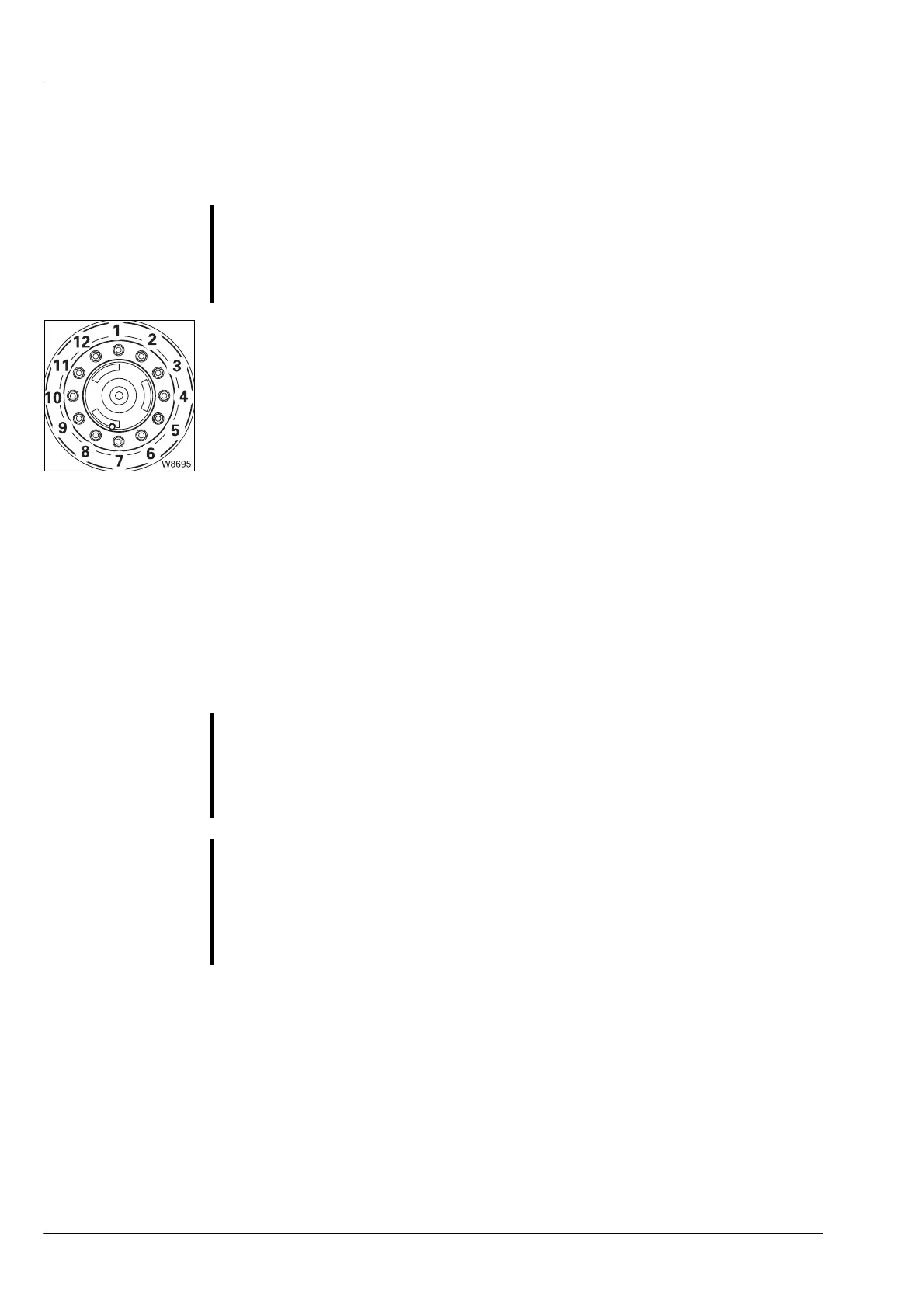

• Remove the wheel nuts (1) to (12) and remove the damaged wheel.

• Secure the wheel against falling over if you set it down temporarily.

On the spare

wheel holder

When changing a wheel, you must remove the spare wheel from the spare

wheel holder and mount the damaged wheel on to the spare wheel holder.

You can use a chain hoist or the truck crane to lift the wheel.

• If you lift the wheel with the truck crane, then:

– Support the truck crane.

– Enter and confirm the current rigging mode.

• Lift the spare wheel using only lifting gear with sufficient load bearing

capacity;

à Spare wheel, p. 1 - 10.

G

Risk of accidents due to a wheel falling over

When unscrewing the final lug nuts, the wheel can slip off the hub and fall

toward you. Secure the wheel and step back quickly if the wheel begins to

tip.

G

Danger of overturning if the truck crane is free-standing

Always support the truck crane on outriggers before rotating the super-

structure.

Never operate the truck crane in the

Free-standing working position if the

tyres are damaged.

G

Risk of overturning while slewing.

Always check before slewing whether slewing is permitted in the truck

crane's current rigging mode (counterweight, outrigger span, working

radius).

Correct the rigging mode if necessary;

à Slewing with rigged counterweight,

p. 12 - 115.

Loading...

Loading...