Rigging work

12.8 Outrigger operation

Operating manual 3 302 736 en 12 - 55

GMK4090

xx.xx.xxxx

12.8.7 Enlarging the load-bearing area

If the surface of the outrigger pads is too small, you must enlarge the load-

bearing area by packing the outrigger pads;

à Determining the required load-

bearing area

, p. 12 - 11.

For packing, use only suitable materials that will withstand the outrigger

pressure, e.g. straight hardwood of similar cross-sections or steel plates

with welded-on strips that will keep the outrigger pads in position.

Level the packing; the outrigger pad must not

be at an angle.

Ensure that the outrigger pressure is evenly

distributed over the packing:

– The outrigger pad must be positioned in the

centre of the packing.

– The outrigger pad must cover all the

wooden planks.

– If the packing has several layers, each layer

must be placed below the other offset by 90°.

– The packing must lie flat on the ground.

Consult your supervisor if you are in doubt.

H

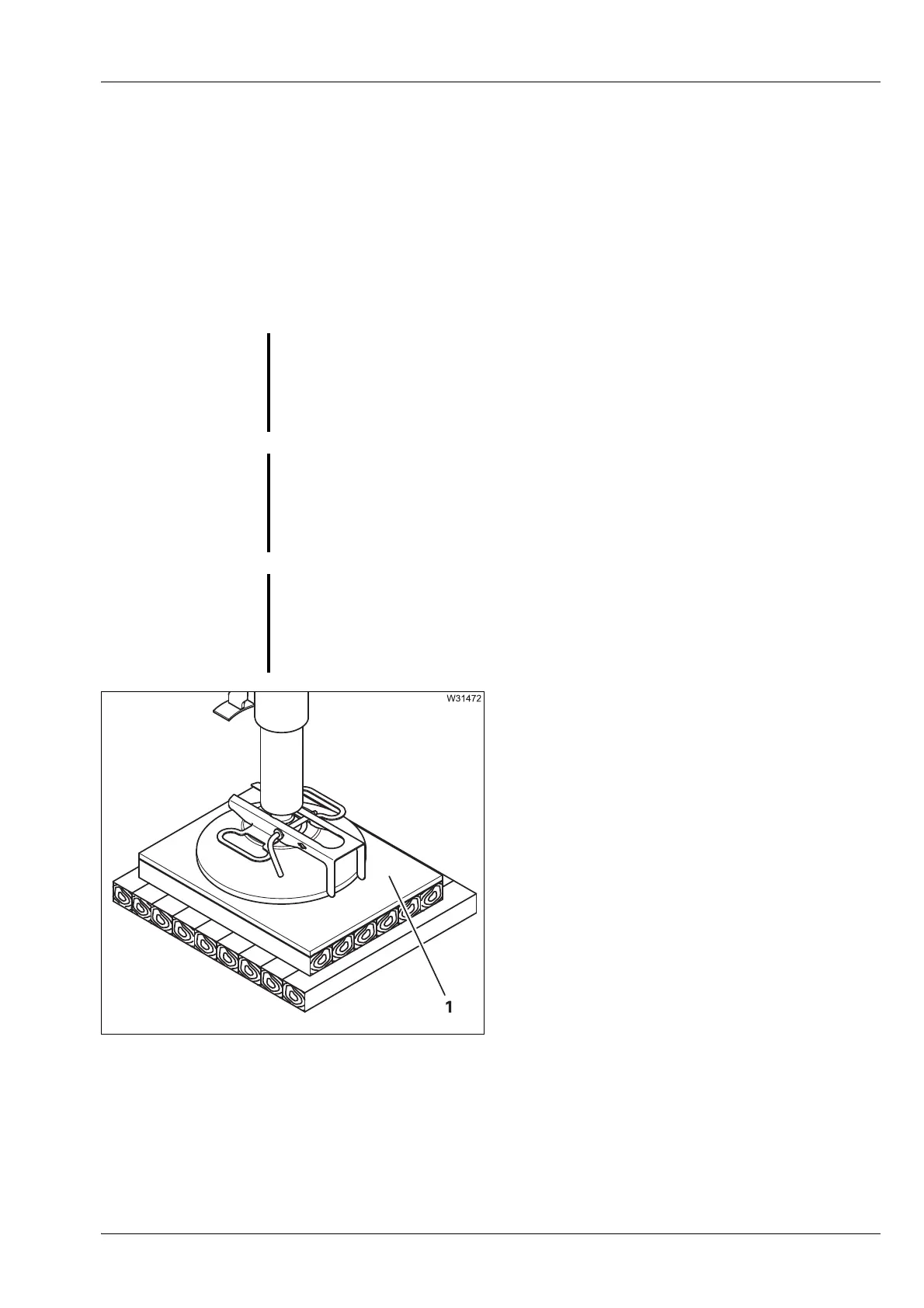

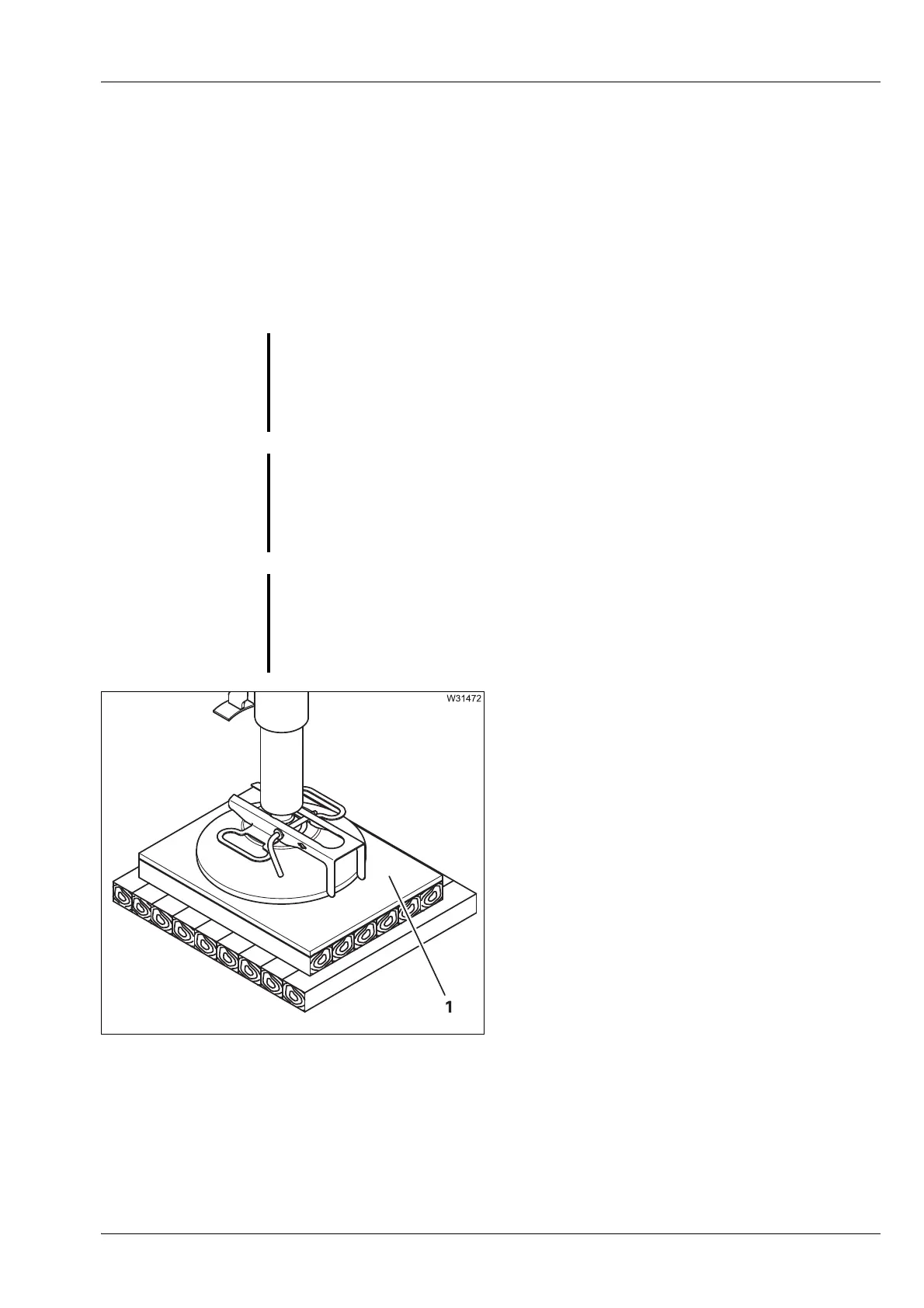

If the truck crane is equipped with plastic outrigger pads then the uppermost

layer of the packing must be a steel plate (1) of sufficient strength.

G

Risk of accidents if the packing is insufficient

Only use materials of sufficient strength.

This will prevent the packing giving way and causing the truck crane to tilt

and overturn.

G

Danger of overturning if the packing or truck crane is at an angle

Level the packing and the truck crane.

This prevents the outrigger pads slipping off the inclined packing and caus-

ing the truck crane to overturn.

S

Risk of damage to the outrigger pads

Always place a steel plate of sufficient strength as the uppermost layer of

the packing if the truck crane is equipped with plastic outrigger pads. This

prevents the outrigger pads being damaged due to one-sided pressure.

Loading...

Loading...