Malfunctions during crane operation

14.5 Emergency operations and programs

14 - 30 3 302 736 en Operating manual

GMK4090

xx.xx.xxxx

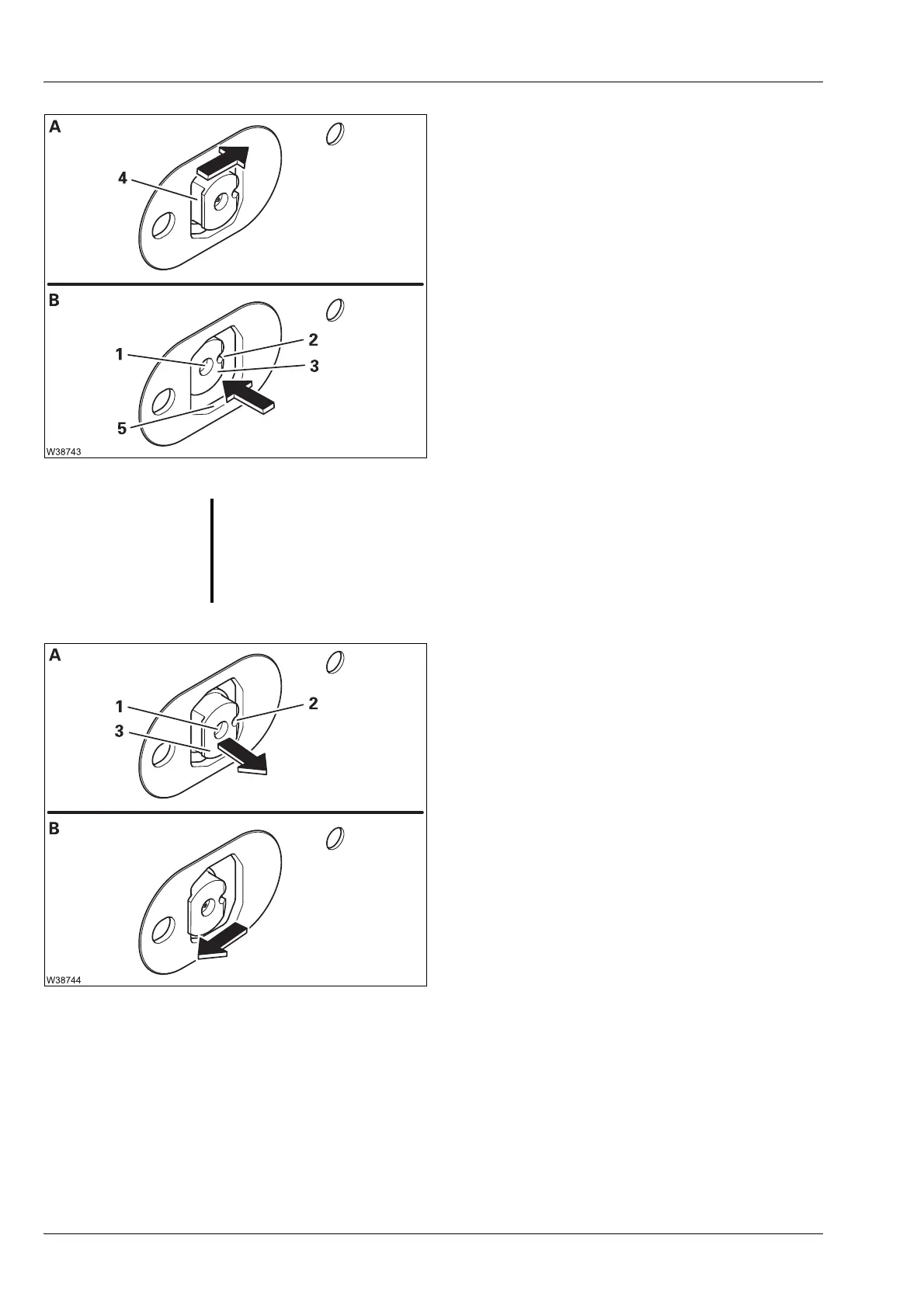

Unlocking lock

• (A) – Extend about 35 mm (0.11 ft), so that

the cutout (4) is accessible.

• (B) – Screw a screw into the hole (1) or (2),

depending on the execution. The locking

pins (2) must retract behind the telescopic

section (3).

If necessary, give the locking pin (3) a slight

knock to help this procedure.

• Unlock the lock on other side of the tele-

scopic section as well.

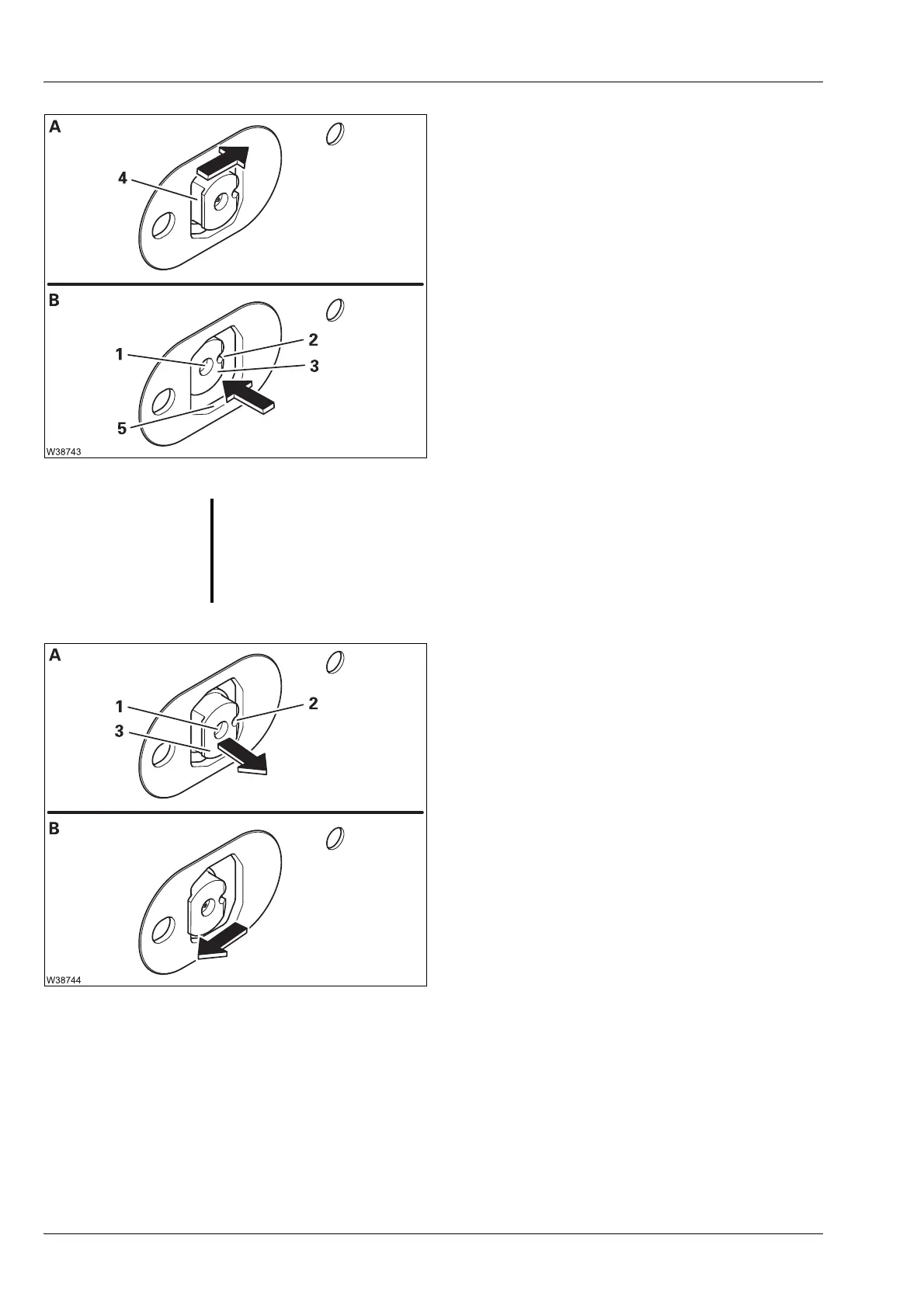

Locking the telescopic section

• (A) – Retract the telescoping until the locking

pin (3) is in the middle of the opening.

• Depending on the execution, unscrew the

screw from the hole (1) or (2) until the lock-

ing pin (2) is extended completely.

• Remove the screw from the hole (1) or (2). If

necessary, install the lubricating nipple

again.

• (B) – Retract the telescoping further until the

telescopic section is set down.

S

Risk of damage due to a mechanically released lock

Under no circumstances may you operate the telescoping cylinder whilst

the lock is mechanically released. Unscrew all bolts out of the bores imme-

diately after finishing the repair work.

This prevents damage to the telescoping cylinder and the locking system.

Loading...

Loading...