MASSO

MASSO Documentation

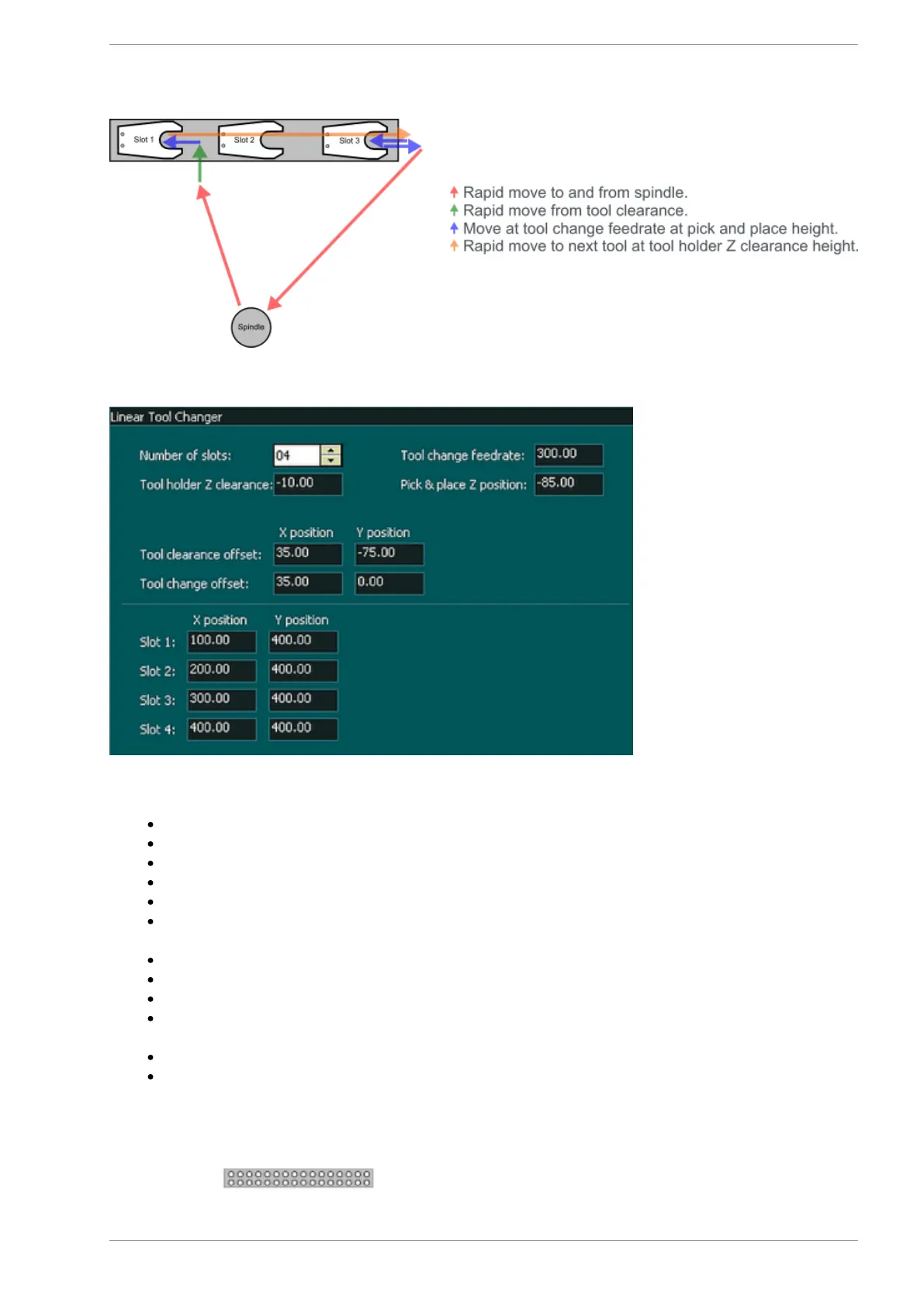

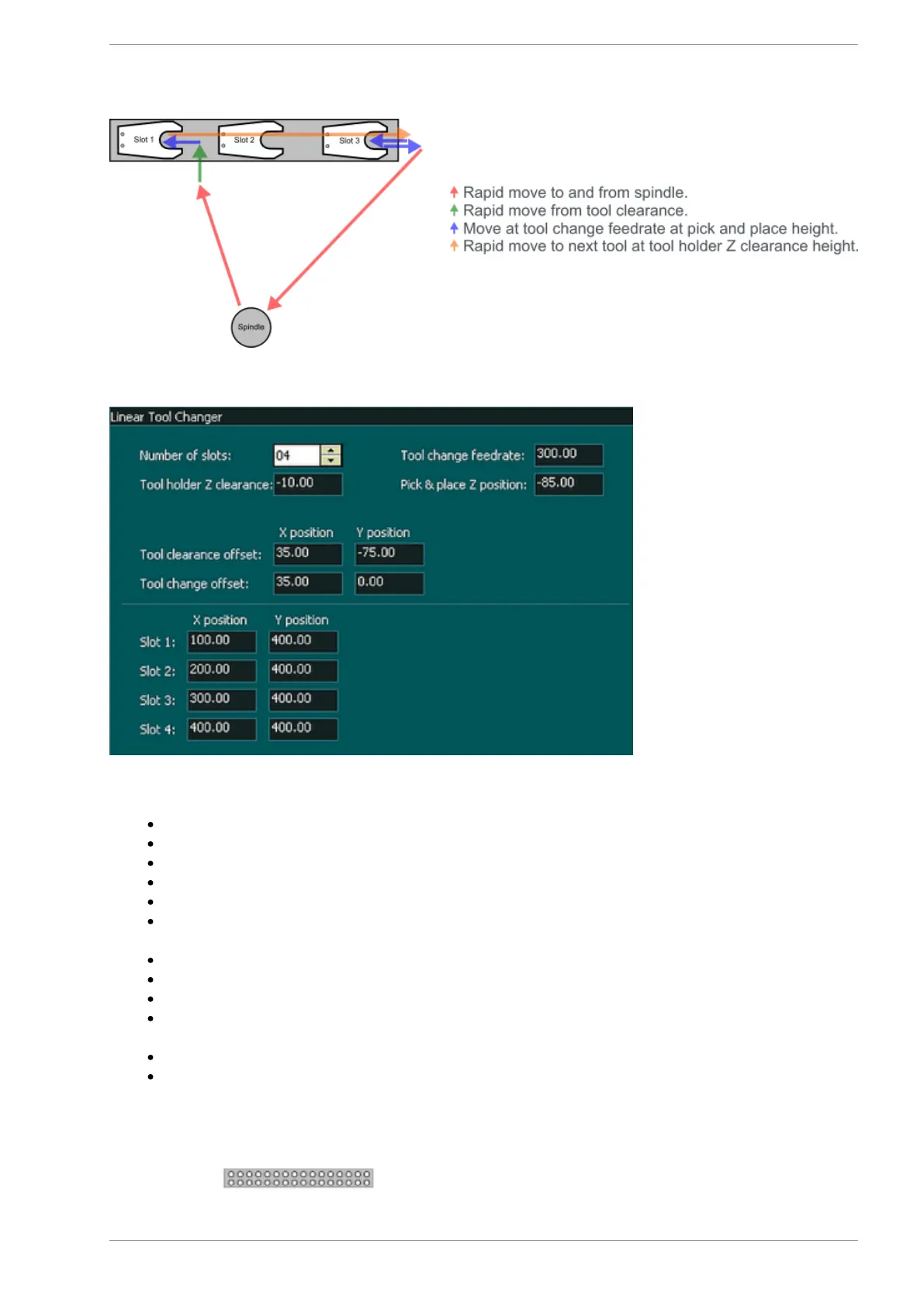

In the following example Tool 1 is in Slot 1 and Tool 2 is in Slot 3

Current tool loaded Tool 1

Gcode T2 M06

Spindle rapids to Machine coordinate X135 Y325 (Tool clearance offset coordinate)

Rapid move to Machine coordinate X135 Y400 (Tool Change offset coordinate)

Move at feed rate 300mm/m at a Machine coordinate Z height of Z-85 to X100 Y400 (Slot 1

Coordinate)

Chuck clamp released and Z rises to Machine coordinate Z-10

Rapid move to X300 Y400 (Slot 3 Coordinate)

Z descends to Z-85 and chuck clamp locks

Move at feed rate 300mm/m at a Machine coordinate Z height of Z-85 to X335 Y400 (Tool Change

offset coordinate)

Z-axis ascends maximum height and rapids to original spindle position

Machining resumes.

Example: 3

v5.18 - 08 Apr,2021

www.masso.com.au Page 417 of 477

Loading...

Loading...