© 2011 MIMAKI ENGINEERING CO.,LTD. 5.2.1 R.2.0 P.1

1

2

3

4

5

6

7

8

Maintenance Manual > Test > Other Test > Ink route leak confirmation procedure

Model UJF-3042/FX Issued 2010.08.27 Revised 2011.09.30 F/W ver 1.80 / 1.00 Remark

2.0

5.2.1 Ink route leak confirmation procedure

Outline

This chapter explains ink route leak confirmation procedure after replacing the dumper adapter and the dumper.

In addition, perform this before attaching ink tube from the cartridge with the dumper port.

Confirmation procedure

1. Connect two dumper ports by the tube 2.5mm in inside diame-

ter.

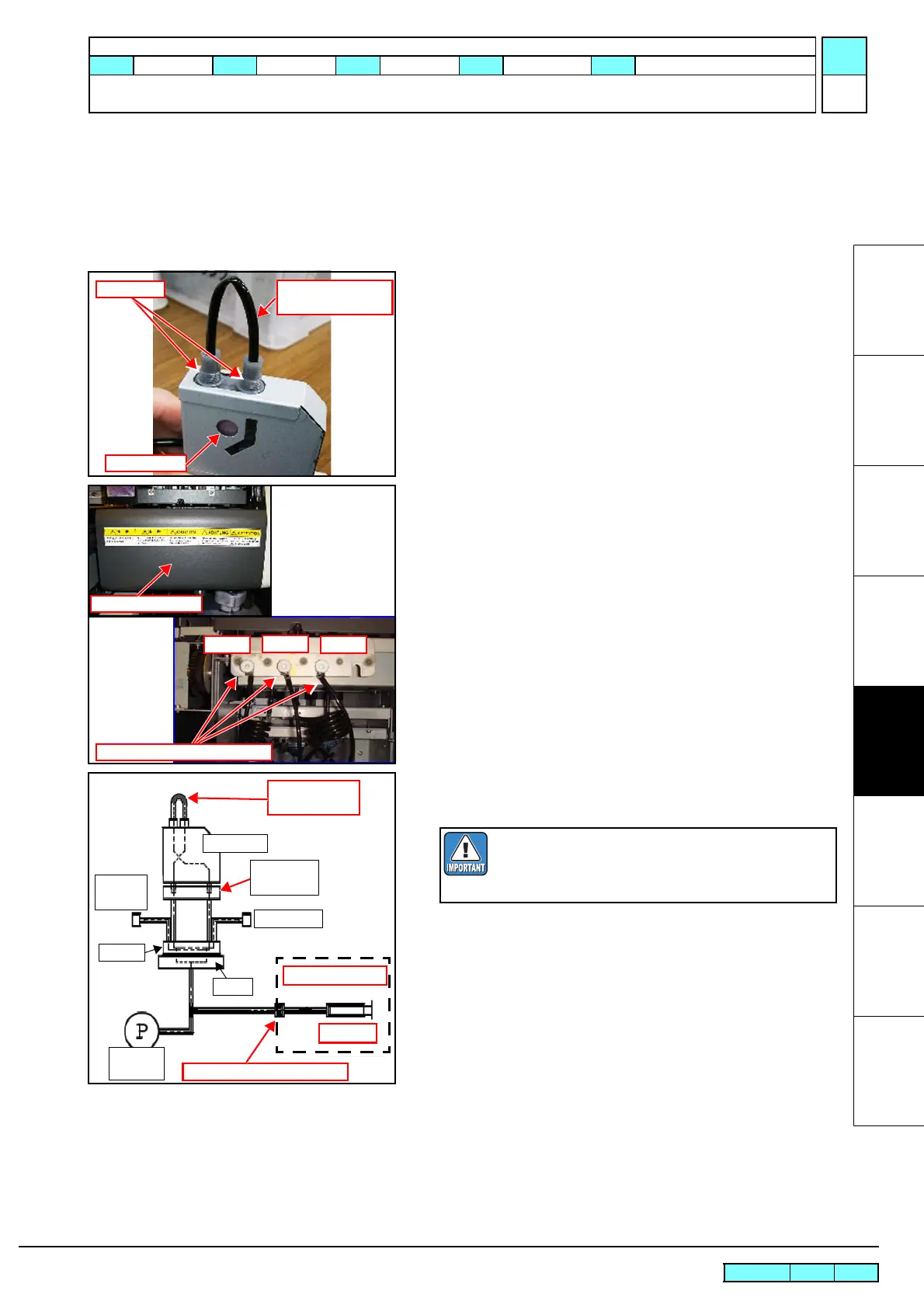

2. Remove the Station Cover.

(Make the port for checking negative pressure usable.)

•Fixing screw x2

3. Attach the Leak Checking jig (Syringe) with the port for check-

ing negative pressure.

4. Check the “Leak”.

• Pull the Piston of syrige.

Criteria

OK: When you pull the piston of the syringe, you feel load, and

if you loose the power to pull, it tries to return backward.

(There is no leak of air and when you pull the piston, the

route becomes in the vacuum status.)

NG: If you can pull the piston of the syringe easily, or even if

you loose the power to pull, it does not return backward.

(There is any leak of air somewhere in the route and air

has entered in the syringe.)

Port

Dumper

Tube(Single Black)

SJ-MMK 2.5 x 4.5

Station Cover

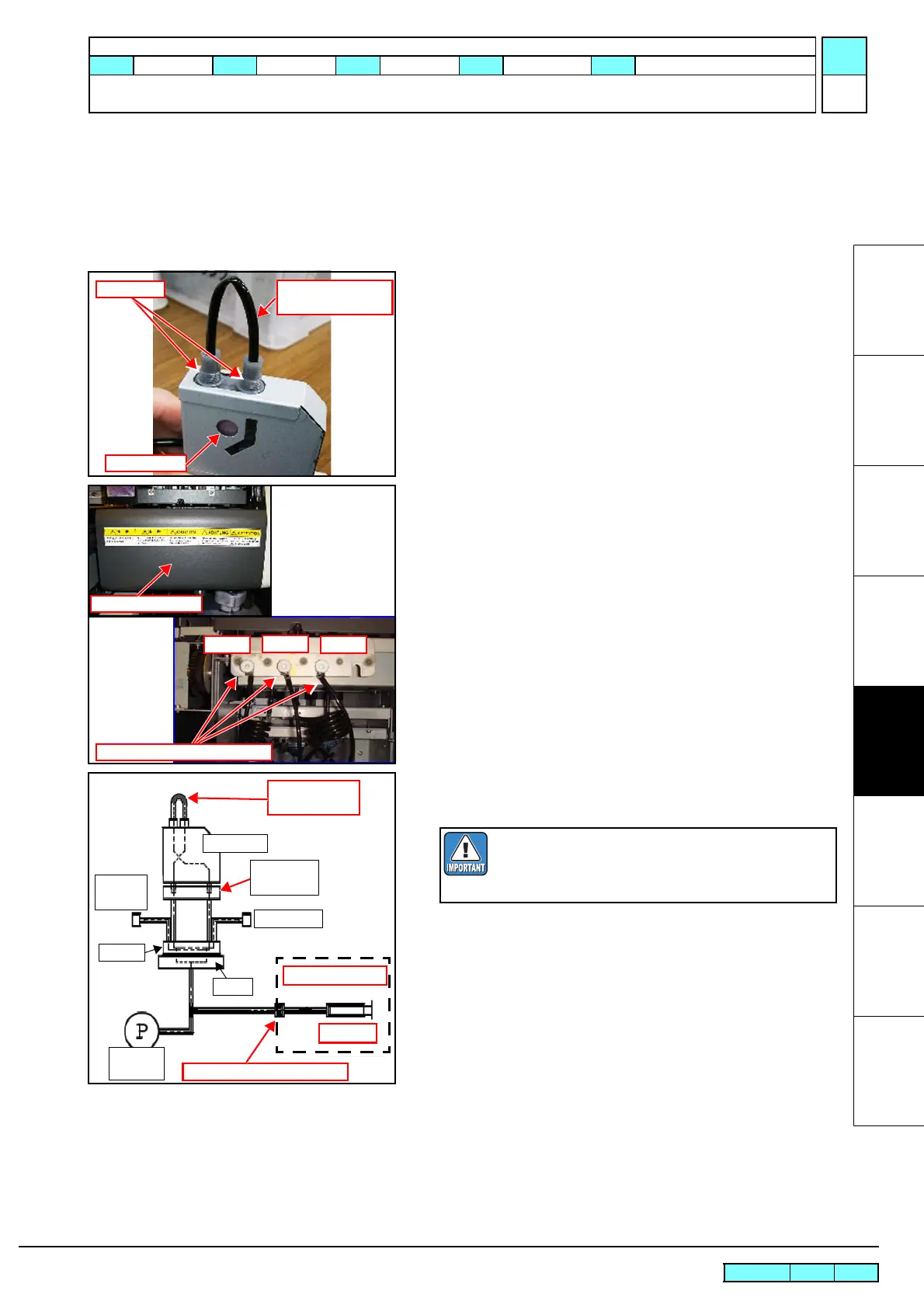

Head1

Head2

Head3

Port for checking negative pressure

Dumper

Tube

Inside 2.5mm

Port for checking negative pressure

Head

Syringe

Tube

pump

Air drain port

Air drain

port

Dumper

Adupter

Cap

Leak Cheking jig

Do not press the piston of the syringe.

It may absorb foreign object into the nozzle and

cause discharging defect.

Loading...

Loading...