© 2011 MIMAKI ENGINEERING CO.,LTD. 4.2.17 R.2.0 P.1

1

2

3

4

5

6

7

8

R.1.1

Maintenance Manual > Adjustment > Adjustment Items > Head Voltage Adjustment

Model UJF-3042/FX Issued 2010.08.27 Revised 2011.09.30 F/W ver 1.80 / 1.00 Remark

2.0

4.2.17 Head Voltage Adjustment

Outline

This section describes the head voltage adjustment which is performed when the ink discharge becomes unstable and

the deflection of ink drop flight path occurs. As an adjusted value, an offset value for the head-specific reference volt-

age is set.

If this adjustment does not improve the situation, the head needs to be replaced.

Check

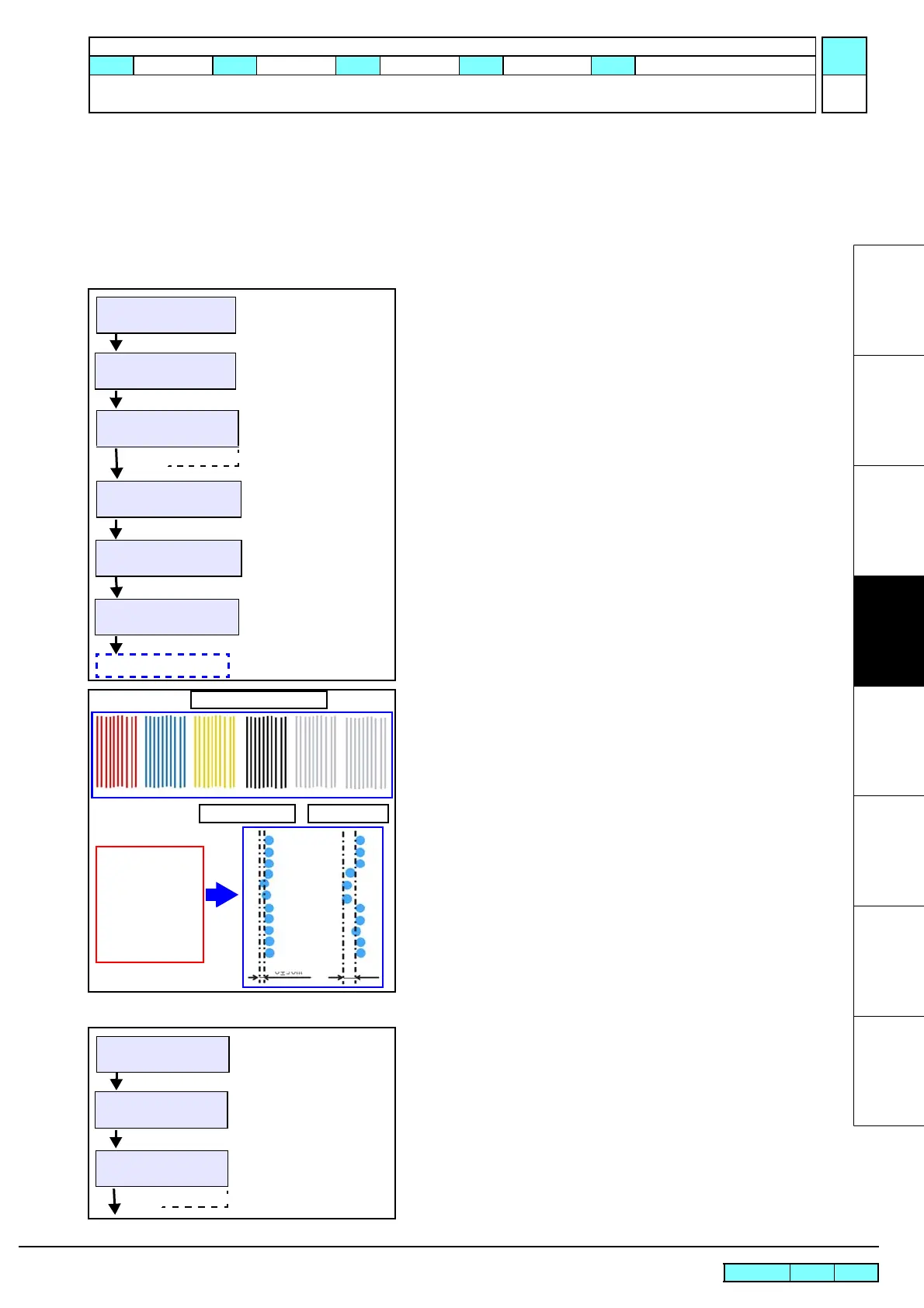

1. Set the media in the table.

2. Select [#ADJUST] -> [HEAD VOLT ADJ].

3. Select “CHECK” for [SELECT].

4. Press [ENTER] and print a pattern.

[ENTER]: Starts printing a pattern.

5. Check the pattern.

Enlarge a single shot line from nozzle row of each color and

check the dots in the line.

If the deviation of each dot in Y direction is within the follow-

ing range, the color (nozzle row) is considered acceptable.

“0 ±30 um

If the deviation is big as shown in “Bad example” in the left fig-

ure, perform the voltage adjustment described below.

Work Procedures

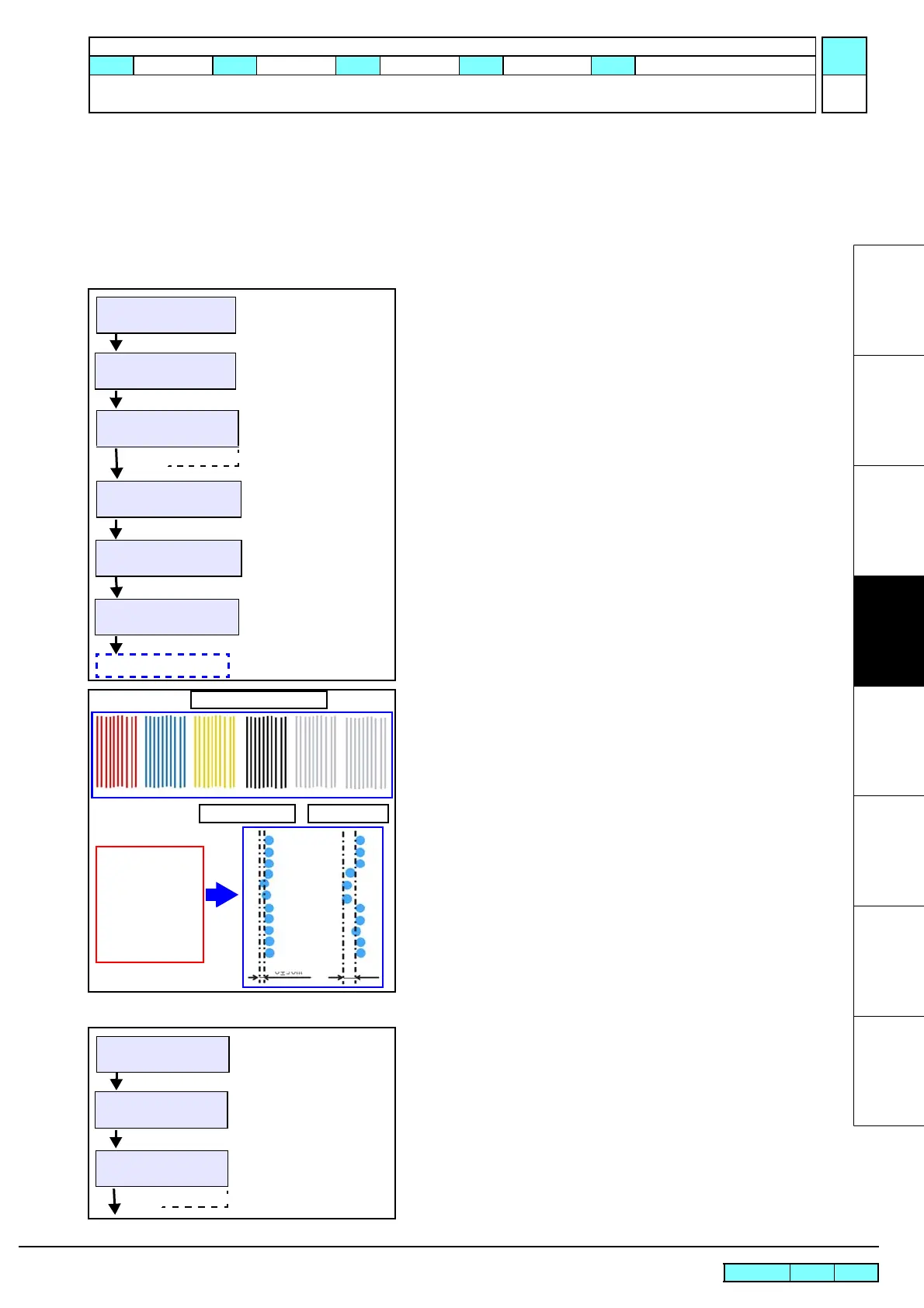

6. Select [#ADJUST] -> [HEAD VOLT ADJ].

7. Select “ADJUST” for [SELECT], and Press [ENTER] key.

FUNCTION

#ADJUST <ent>

#HEAD VOLT ADJUST

SELECT :CHECK

#HEAD VOLT ADJUST

PRINTING

ADJUST

#HEAD VOLT ADJUST

PRINT START :ent

HEAD TEMP. CONTROL

PLEASE WAIT

Patern Drawing

#ADJUST

HEAD VOLT ADJ <ent>

Good example

Single shot from one

nozzle row

Acceptable deviation

of each dot in the same

nozzle row:

“0

±

30 um”

0~30um

Check Patern (all color)

Bad example

FUNCTION

#ADJUST <ent>

#ADJUST

HEAD VOLT ADJ <ent>

#HEAD VOLT ADJUST

SELECT :ADJUST

CHECK

Loading...

Loading...