8 Operation

Maschinenfabrik Reinhausen GmbH 2020184 3587317/21 ENTAPCON

®

▪ Desired load stress type

▪ Parallel operation error delay time

Note that the parameters "Error if no communication" and "Behavior if no

communication" have no function in the circulating reactive current mini-

mization without CAN communication parallel operation method.

8.18.1.4 Tap stagger (optional)

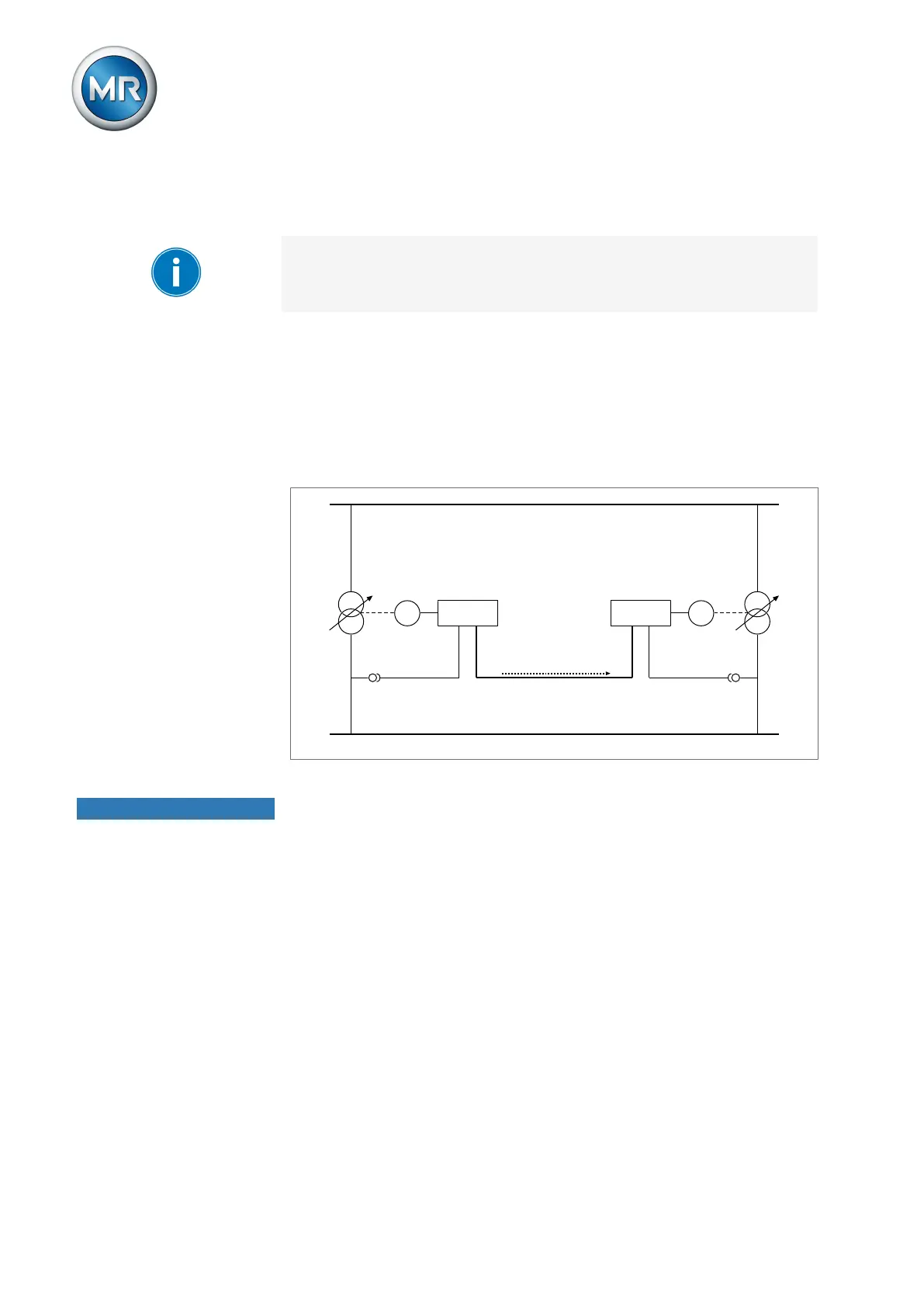

The tap stagger parallel operation method is used to generate a defined cir-

culating reactive current in two transformers running in parallel in order to

compensate for the reactive power in the grid. In this case, one voltage regu-

lator works as the master and one voltage regulator as the follower. The

master handles voltage regulation and transmits the desired tap position to

the follower over the CAN bus.

Master Follower

Tap position

CAN bus

M AVR MAVR

T1 T2

Figure127: Tap stagger

NOTICE

Damage to the transformers

An inadmissibly high circulating reactive current can lead to the transform-

ers being damaged.

► Ensure that the circulating reactive current generated through the tap

stagger parallel operation method does not exceed the performance lim-

its of the transformers.

Function To generate a defined circulating reactive current, you must select the de-

sired tap stagger level. Starting from the same tap position, the master and

follower then switch in opposing directions (e.g. tap stagger level = 2: master

+1, follower -1). The magnitude of the circulating reactive current depends

on how large the tap position difference is between the master and follower.

The on-load tap-changers switch in opposing directions based on the setting

of the selected parameter until the desired tap stagger level is reached.

Loading...

Loading...