8 Operation

Maschinenfabrik Reinhausen GmbH 2020226 3587317/21 ENTAPCON

®

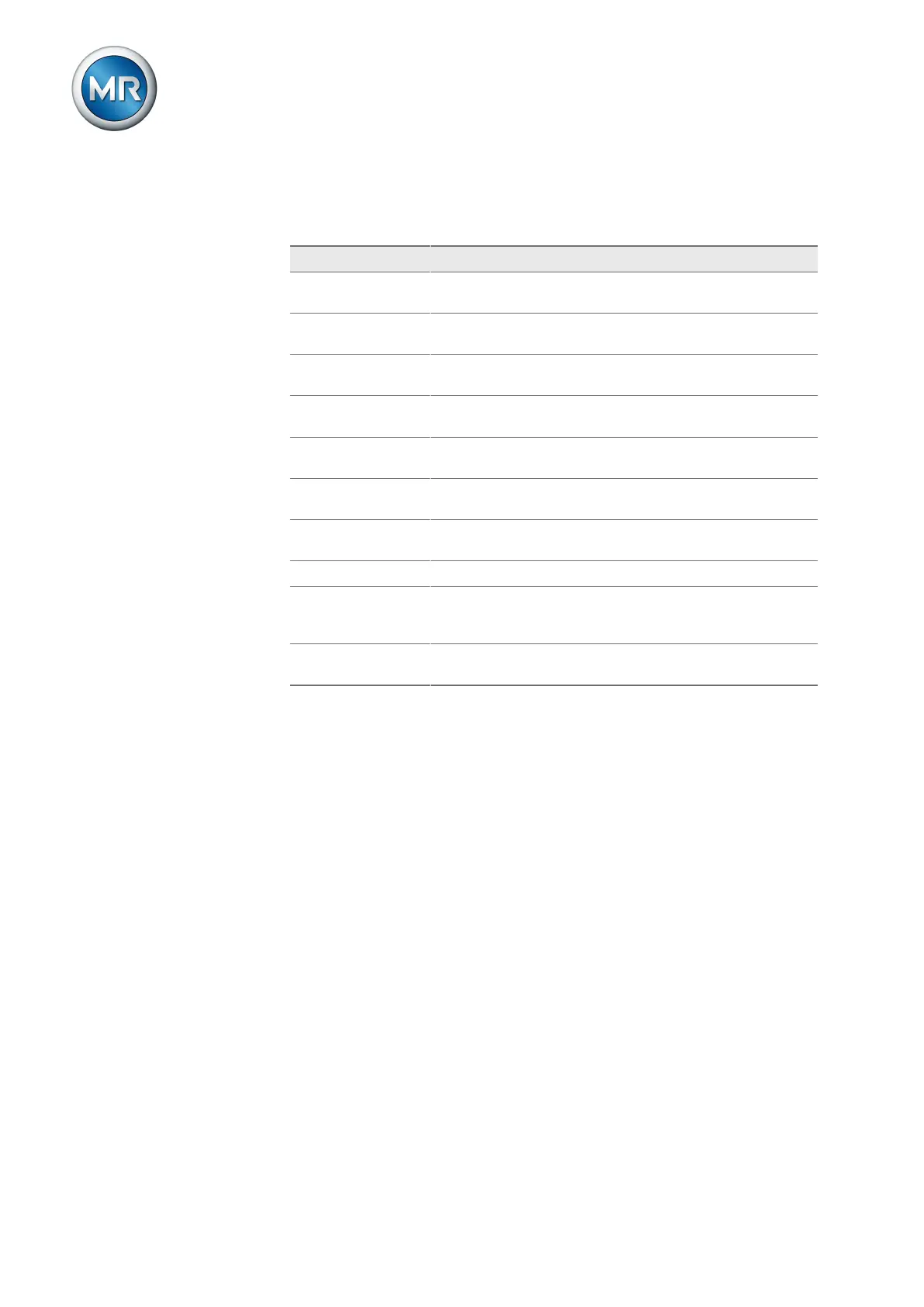

8.22 Maintenance (optional)

The device monitors the following maintenance:

Maintenance Description

OLTC maintenance The on-load tap-changer must be maintained in accordance

with the MR standards.

OLTC replacement The on-load tap-changer must be replaced with a new on-

load tap-changer.

DSI replacement The diverter switch insert must be replaced with a new di-

verter switch insert.

Contact wear The main switching contacts or transition contacts of the on-

load tap-changer must be exchanged or replaced.

Oil change and

cleaning

The oil must be changed and the diverter switch insert, oil

compartment, and oil conservator must be cleaned.

Selector mainte-

nance

The on-load tap-changer selector must be maintained in ac-

cordance with the MR standards.

Oil sample An oil sample must be taken and analyzed; the limit values

specified by MR for added insulating oil must be observed.

Oil filter unit The oil filter of the oil filter unit must be replaced.

OLTC operator inter-

val

Maintenance interval for the on-load tap-changer; the interval

depends on the number of tap-change operations or on time,

and the operator can specify it.

Transformer opera-

tor interval

Time-dependent maintenance interval for the transformer,

which the operator can specify.

Table80: Maintenance tasks

Loading...

Loading...