B245/B276/B277/B268/B269 Service Manual 18-Jan-06

249

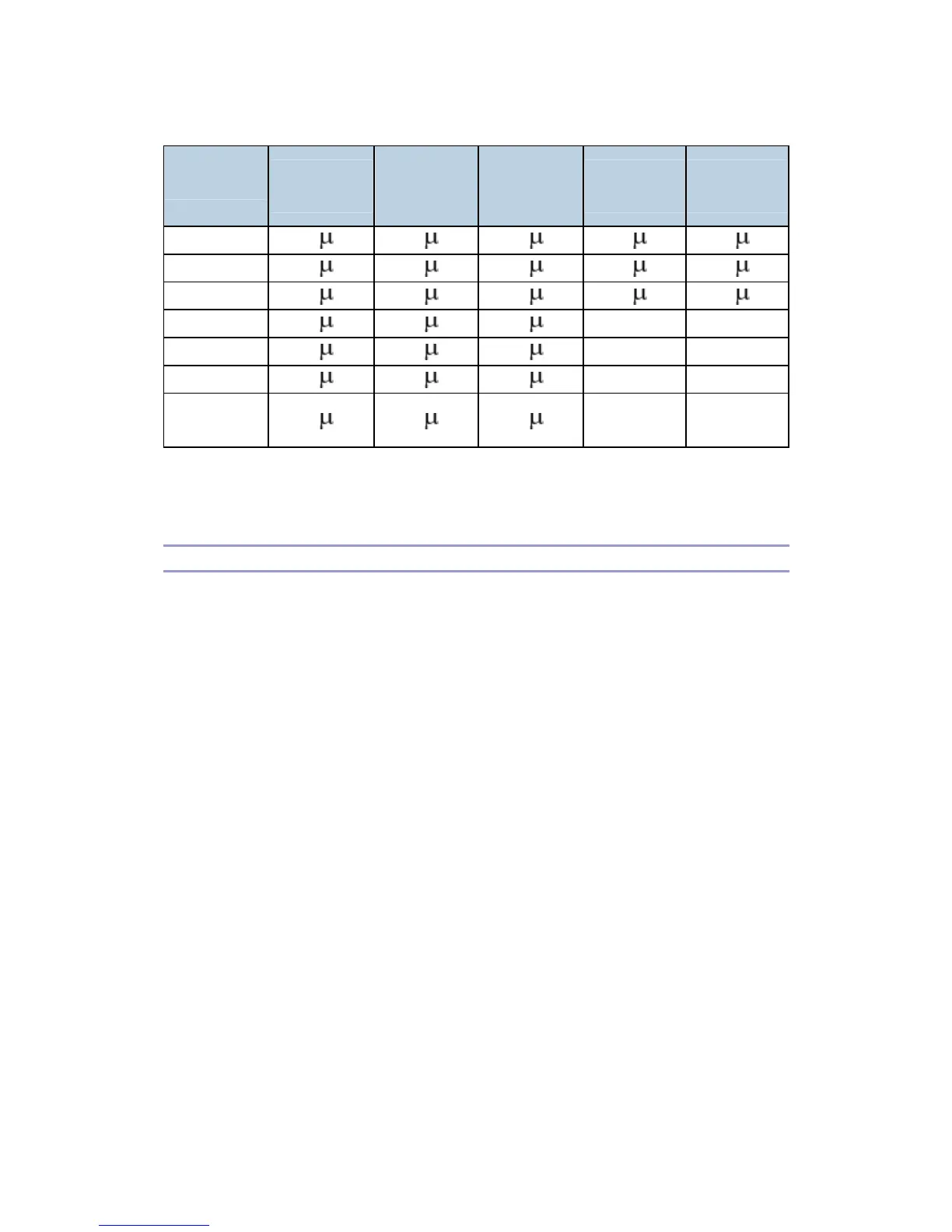

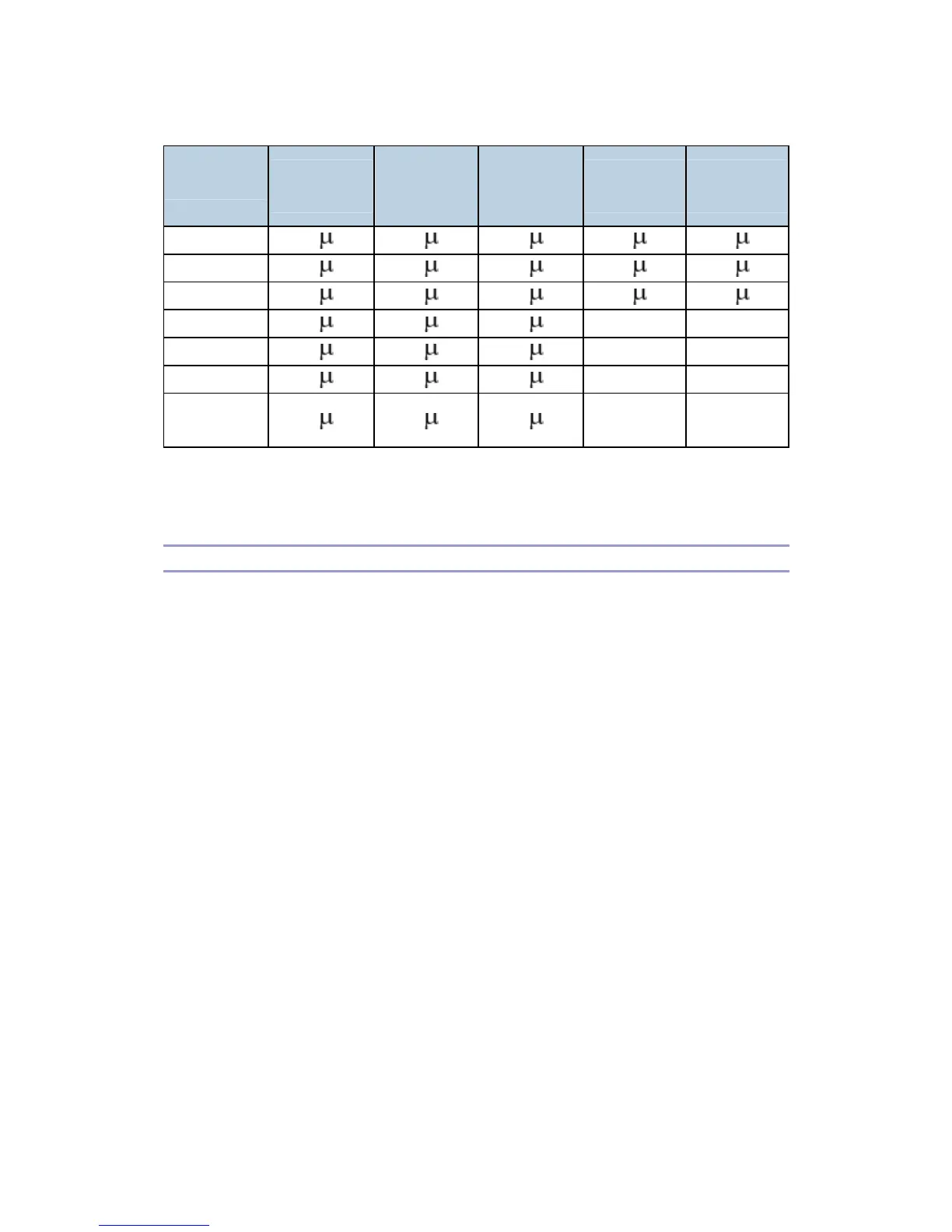

By-pass Tray

(Thick/OHP)

Paper Tray/

By-pass Tray

(Normal)

By-pass Tray

(Special/

Envelope)

Duplex

(2nd Side)

Duplex

(2nd Side)

A4 SEF

21

A 15

A 28

A 15

A 24

A

B5 SEF

22

A 19

A 28

A 19

A 22

A

A5 SEF

22

A 19

A 28

A 19

A 28

A

HLT SEF

22

A 19

A 28

A

— —

B6 SEF

22

A 19

A 28

A

— —

A6 SEF

22

A 19

A 34

A

— —

Post card/

Envelope

22

A 19

A 34

A

— —

Be careful when increasing the transfer current. This may cause a ghosting effect, in which

part of the image at the top of the page is repeated lower down the page at a lower density. In

the worst case, it may also damage the OPC drum.

Transfer Roller Cleaning

If the paper size is smaller than the image, or if a paper jam occurs during printing, toner may

be transferred to the roller surface. To prevent the toner from transferring to the back side of

the printouts, the transfer roller requires cleaning before the next printing run.

During transfer roller cleaning, the high voltage supply unit supplies a negative cleaning

voltage (about –1 kV) to the transfer roller. Any negatively charged toner on the transfer roller

is then transferred back to the drum. Then a positive cleaning current (+10 microamperes) is

applied to the transfer roller to push back to the drum any positively charged toner on the

transfer roller.

The machine goes through the cleaning mode in the following conditions:

Before starting the printing job (only if enabled with SP 2996; note that the default setting

is off).

Just after the power is switched on.

After a copy jam has been cleared.

After 10 or more sheets of paper have been copied and the copy job has finished.

Also, the transfer roller cleaning current can be adjusted using SP 2301 4.

Loading...

Loading...