Section 04 FUEL SYSTEM

Subsection 02 (FUEL TANK AND FUEL PUMP)

GENERAL

WARNING

Fuel lines remain under pressure at all times.

Always proceed with care and use appro-

priate safety equipment when working on a

pressurized fuel system. Wear safety glasses.

WARNING

Always disconnect battery prior to work-

ing on the fuel system. Fuel vapors are

flammable and explosive under certain con-

ditions. Always work in a well ventilated

area. Do not allow fuel to spill on hot en-

gine parts and/or on electrical connectors.

Proceed with care when removing/installing

high pressure test equipment or disconnect-

ing fuel line connections. Cover the fuel

line connection with an absorbent shop rag.

Wipe off any fuel spillage in the bilge.

WARNING

When the repair is completed, ensure that

hoses and connections from fuel rail to the

fuel pump are properly secured. Then, pres-

surize the fuel system. After carrying out a

fuel pump pressure test, use the valve on the

fuel pressure gauge to release the pressure

(if so equipped).

WARNING

The fuel pump is energized for a few seconds

each time the START button is depressed.

It builds fuel system pressure very quickly.

Prior to pressing the START button, ensure

there are no disconnected or damaged fuel

lines that may leak fuel. A high pressure

leak test must be carried out whenever a fuel

system component has been disconnected.

WARNING

Ensure wires and hoses are routed and se-

cured away from any vibrating, rotating,

moving or hot components or sharp edges.

Use appropriate shields and fastening de-

vices as per factory standards.

NOTICE

Whenever repairing the fuel system,

always check for water infiltration in the fuel

tank. Replace any damaged, leaking or deteri-

orated fuel line.

SYSTEM DESCRIPTION

The fuel system is comprised of:

– A fuel tank

– A vented fuel tank cap

– A fuel pump module mounted inside the fuel

tank

– A variety of hoses.

The fuel pump module is basically comprised of:

– An electric fuel pump mounted inside a canister

type pump reservoir

– A lower inlet filter

– An upper outlet filter

– A pressure regulator

– A float type fuel level sensor.

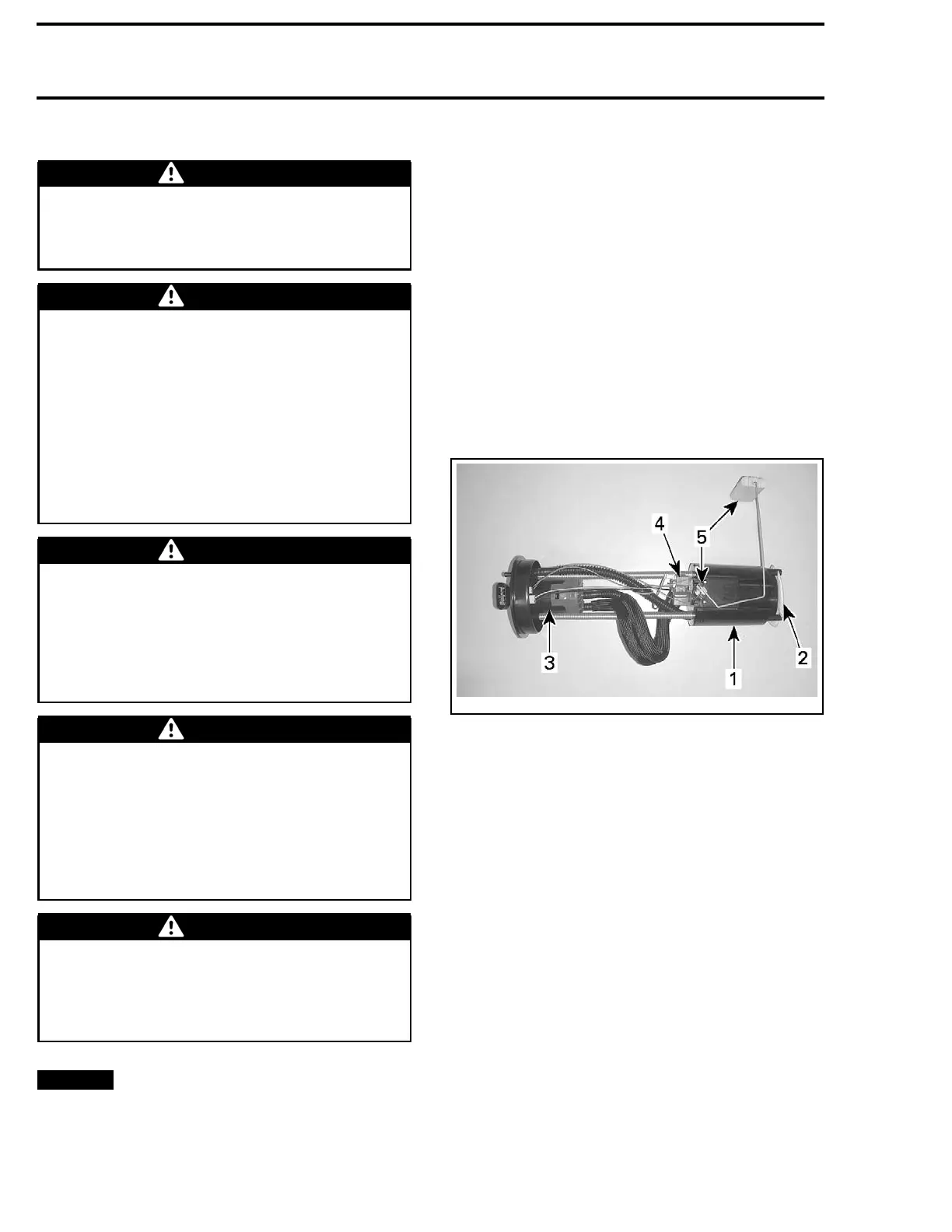

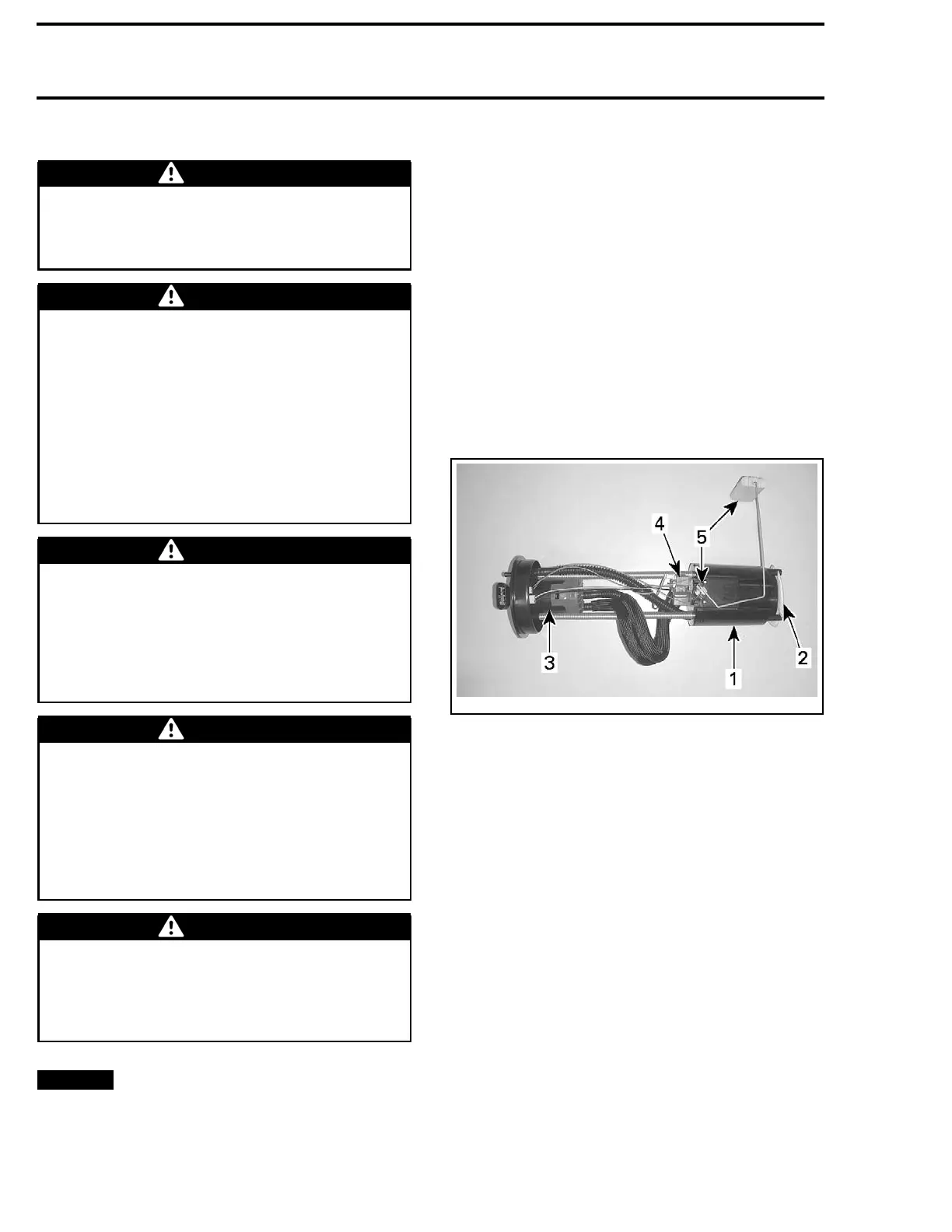

smr2008-022-007_a

FUEL PUMP MODULE

1. Fuel pump reservoir

2. Lower inlet f ilter

3. Upper outlet filter

4. Fuel pressure regulator

5. Float type fuel level sensor

Fuel Pump Operation

When the pump is in operation, it draws fuel into

the canister through a lower inlet filter and a disk

type valve.

The pressurized fuel is pushed through an upper

outlet filter to the fuel rail.

Excess fuel pressure generated by the pump is

routed from the upper filter back to the pump can-

ister reservoir by a pressure regulator mounted on

the pump reservoir cover.

When the START button is pressed, the electrical

system is powered. The fuel pump will come on

for approximately 2 seconds to pressurize the fuel

rail in preparation for the engine start.

The ECM supplies the ground signal to turn on the

fuel pump motor.

The pressure regulator will ensure appropriate

fuel pressure is supplied to the injectors.

90 219100893-021

Loading...

Loading...