Section 06 ST EE RING AND PROPULSION

Subsection 02 (iBR, REVERSE AND VTS)

BRAKE AND REVERSE LEVER

SWITCH (BRLS)

Testing and Specifications

BRLS PINOUT

PIN SIGNAL

BRLS-A 5 VDC

BRLS-B GND

BRLS-C View signal % in BUDS2

BRLS-D 5VDC

BRLS-E GND

BRLS-F View signal % in BUDS2

NOTE: When moving BRLS lever, the BRLS per-

centage should increase or decrease in a steady

linear fashion.

If BUDS2 does not show BRLS percentage mov-

ing or if reading is erratic:

– Check for BRLS reference voltage.

– Check for BRLS ground.

– Carry out a continuity test of the w iring be-

tween the iBR actuator and the BRLS.

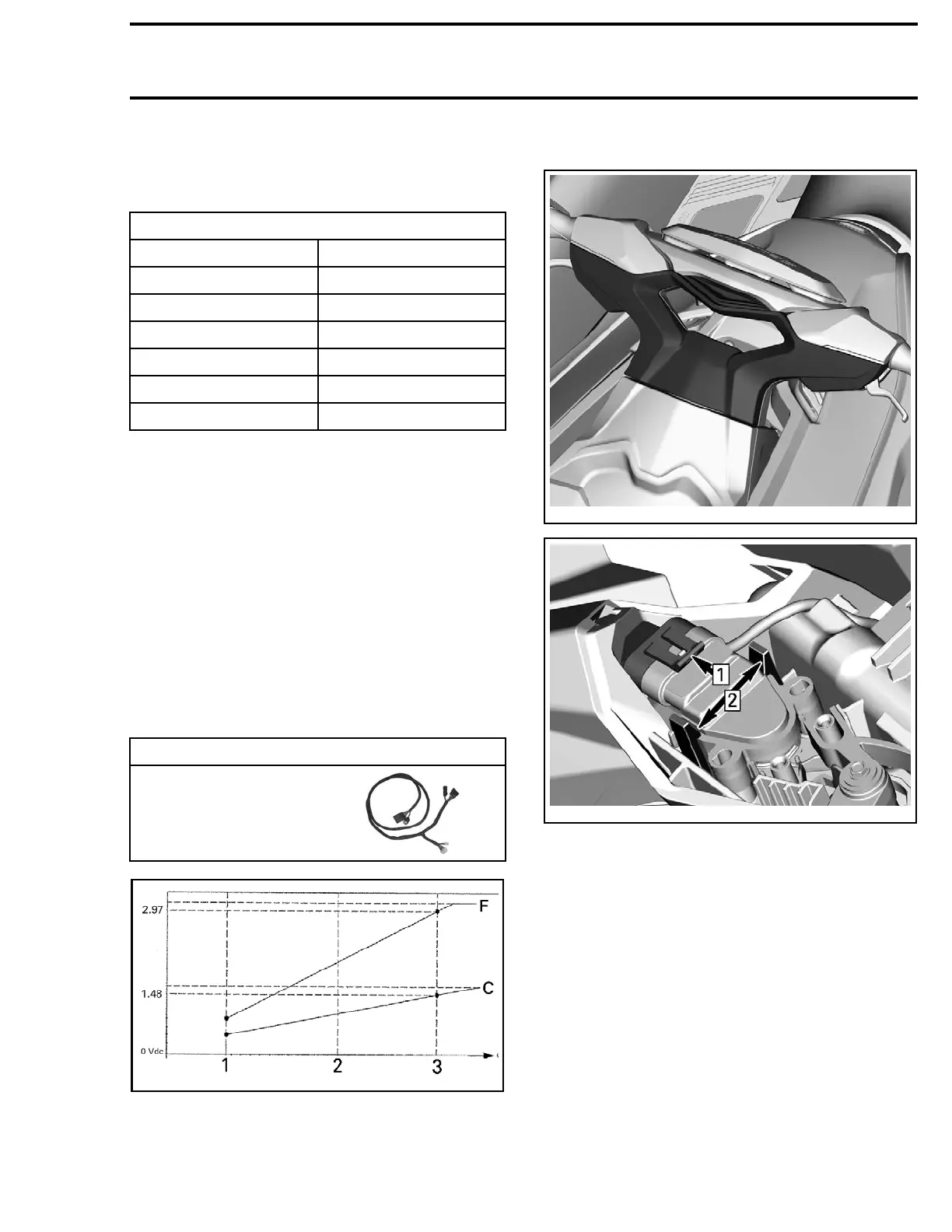

NOTE: When installed on vehicle the BRLS-C Vdc

signal should always be half of the BRLS-F Vdc

signal when testing with a multimeter.

To test, install Diagnostic harness between steer-

ing harness connectors.

REQUIRED TOOL

DIAGNOSTIC HARNESS

(P/N 529 036 384)

smr2014-119-017_a

APPROXIMATE BRLS SIGNAL VOLTAGE CURVE PINS F AND C

1. BRLS released

2. BRLS at 50% pulled

3. BRLS fully pulled

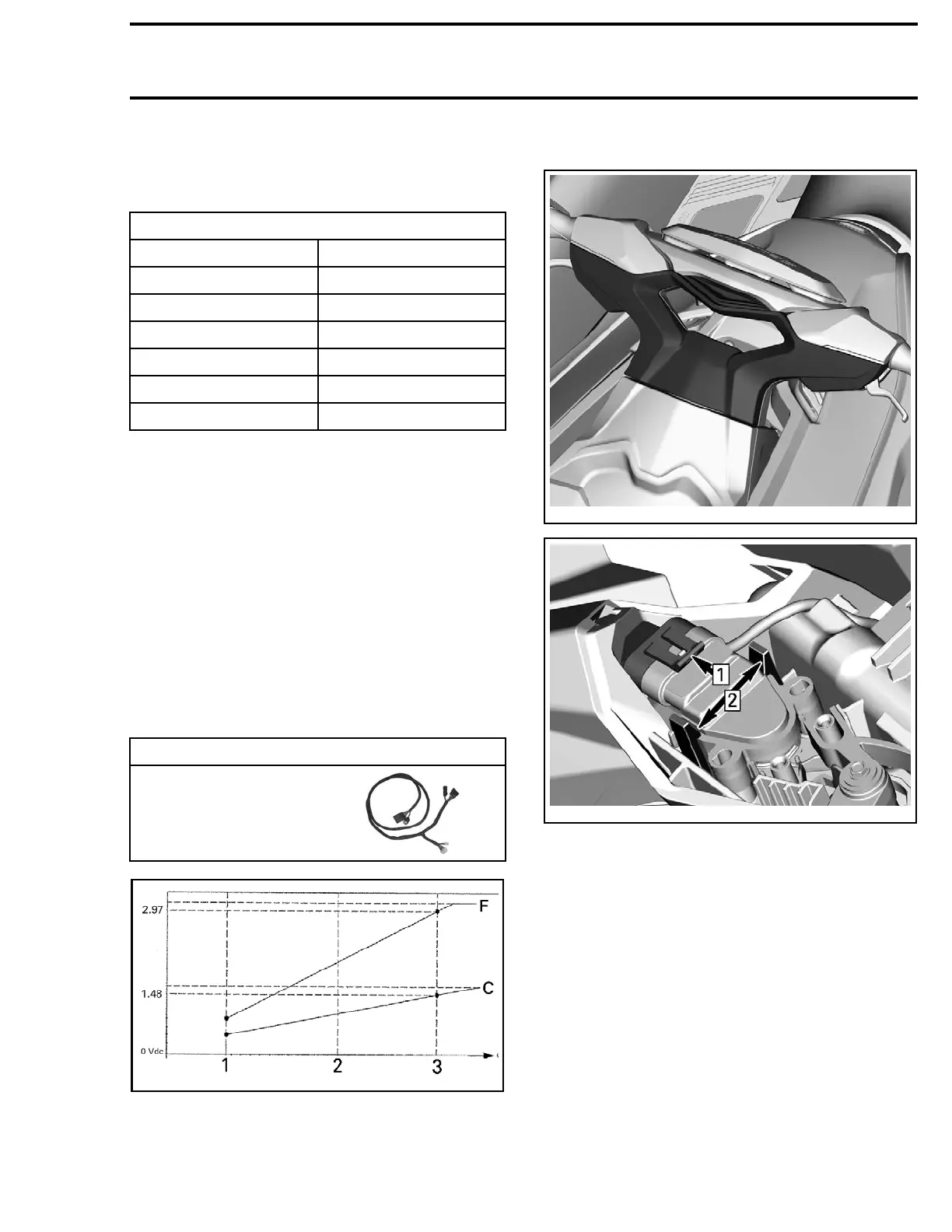

Removing the BRLS

219100893-029-019_a

smr2014-119-013_a

Installing the BRLS

The installation is the reverse of the removal pro-

cedure.

219100963-018 181

Loading...

Loading...